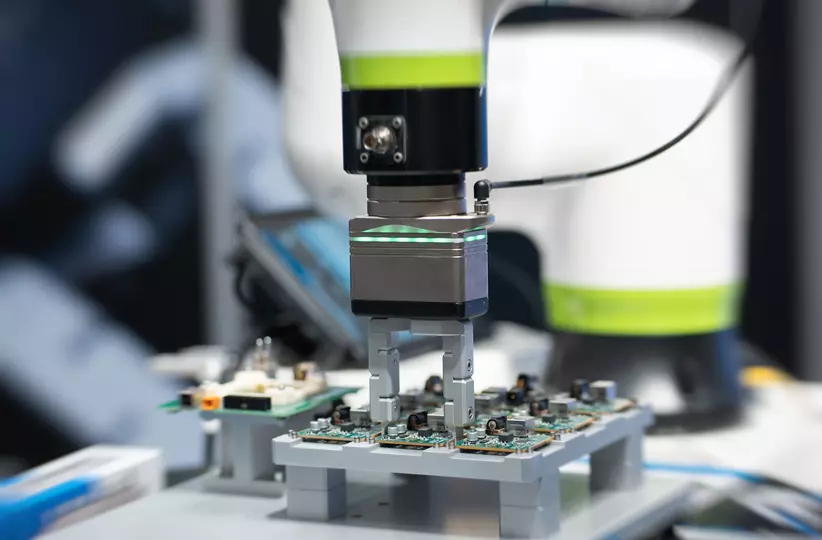

Sestavljanje

Poenostavite proces sestavljanja z montažnimi roboti FANUC

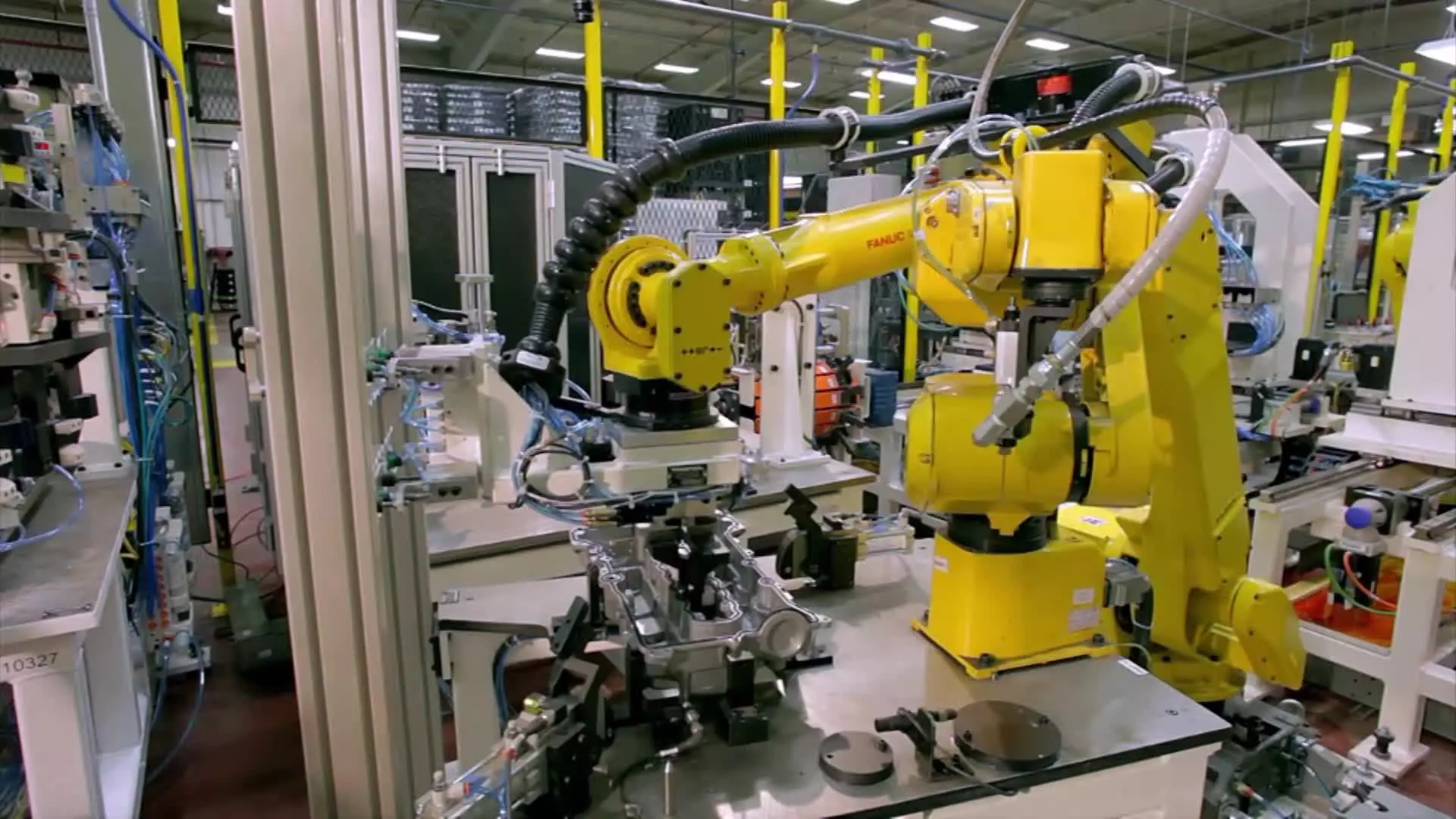

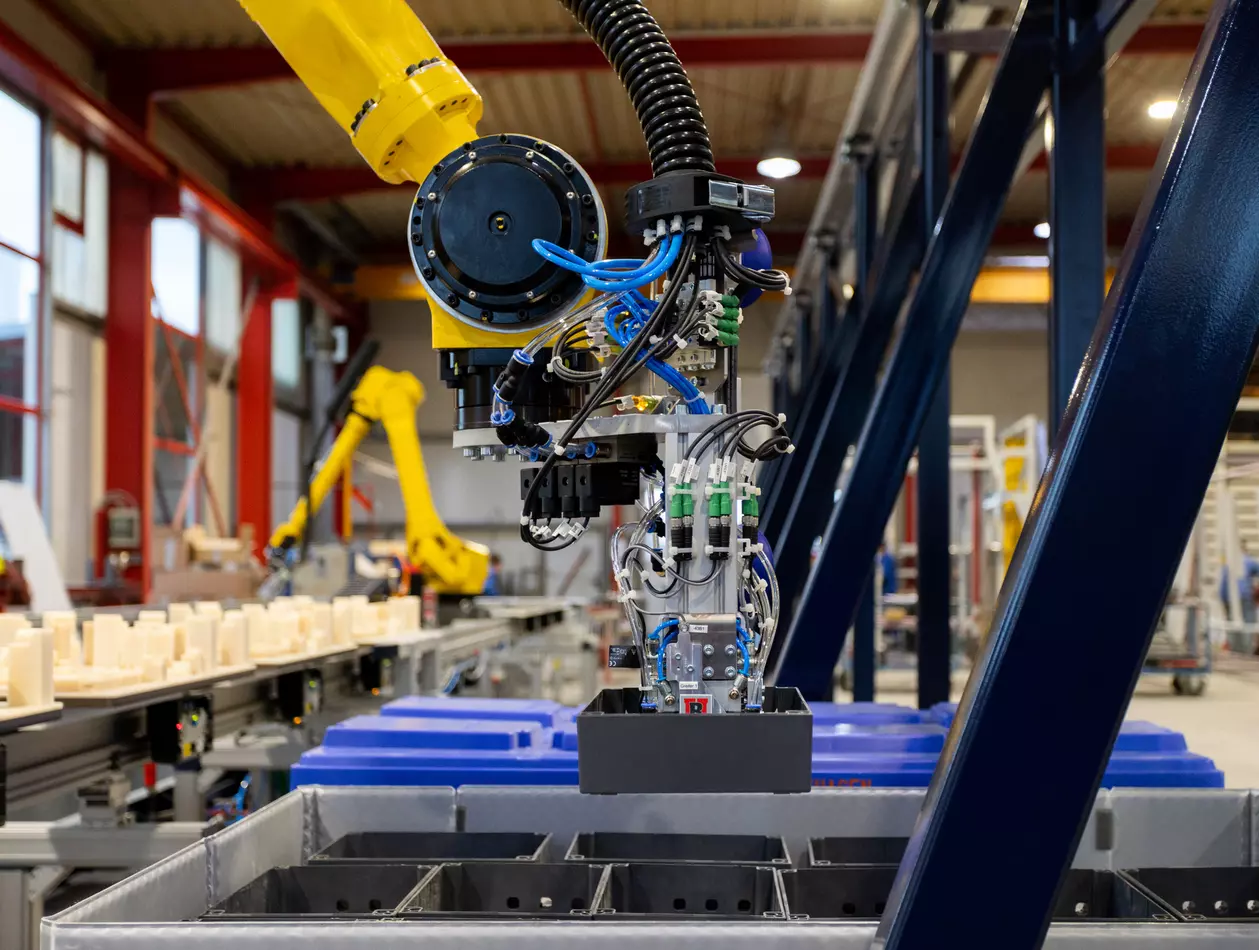

Roboti FANUC so oblikovani za visoko učinkovitost in natančnost. Odlikuje jih napredna tehnologija za večjo učinkovitost, vključno z visoko hitrostjo delovanja, velikim koristnim tovorom in izjemno natančnostjo. Ti industrijski roboti so izdelani iz trpežnih materialov, kar zagotavlja dolgo življenjsko dobo in zanesljivost v različnih industrijskih okoljih. Opremljeni so z uporabniku prijaznimi vmesniki in združljivi s perifernimi napravami, zato je njihova integracija v obstoječe sisteme nemotena. Varnost je prednostna naloga in zagotavlja nemoteno delovanje. Poleg tega roboti FANUC omogočajo prilagodljivost pri namestitvi in so primerni za široko paleto aplikacij, od sestavljanja majhnih delov do težkih nalog.

Navdihnite se

Navdihujte se z uspehi drugih

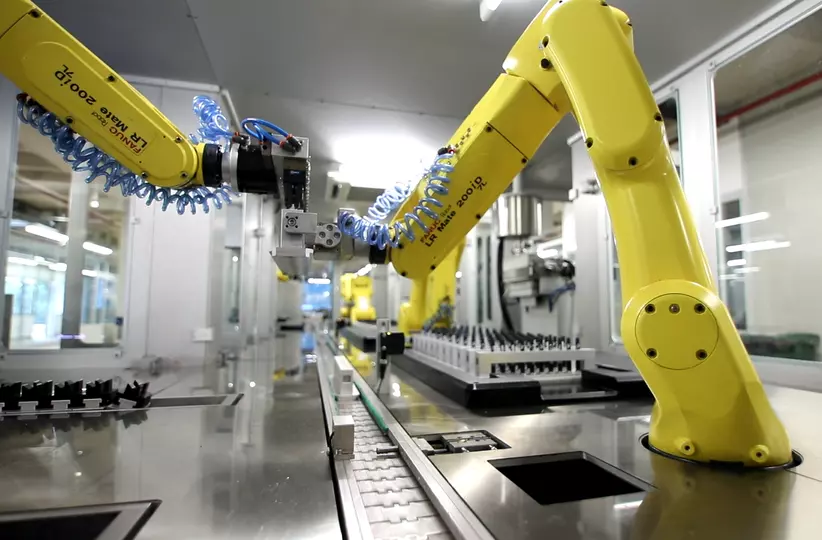

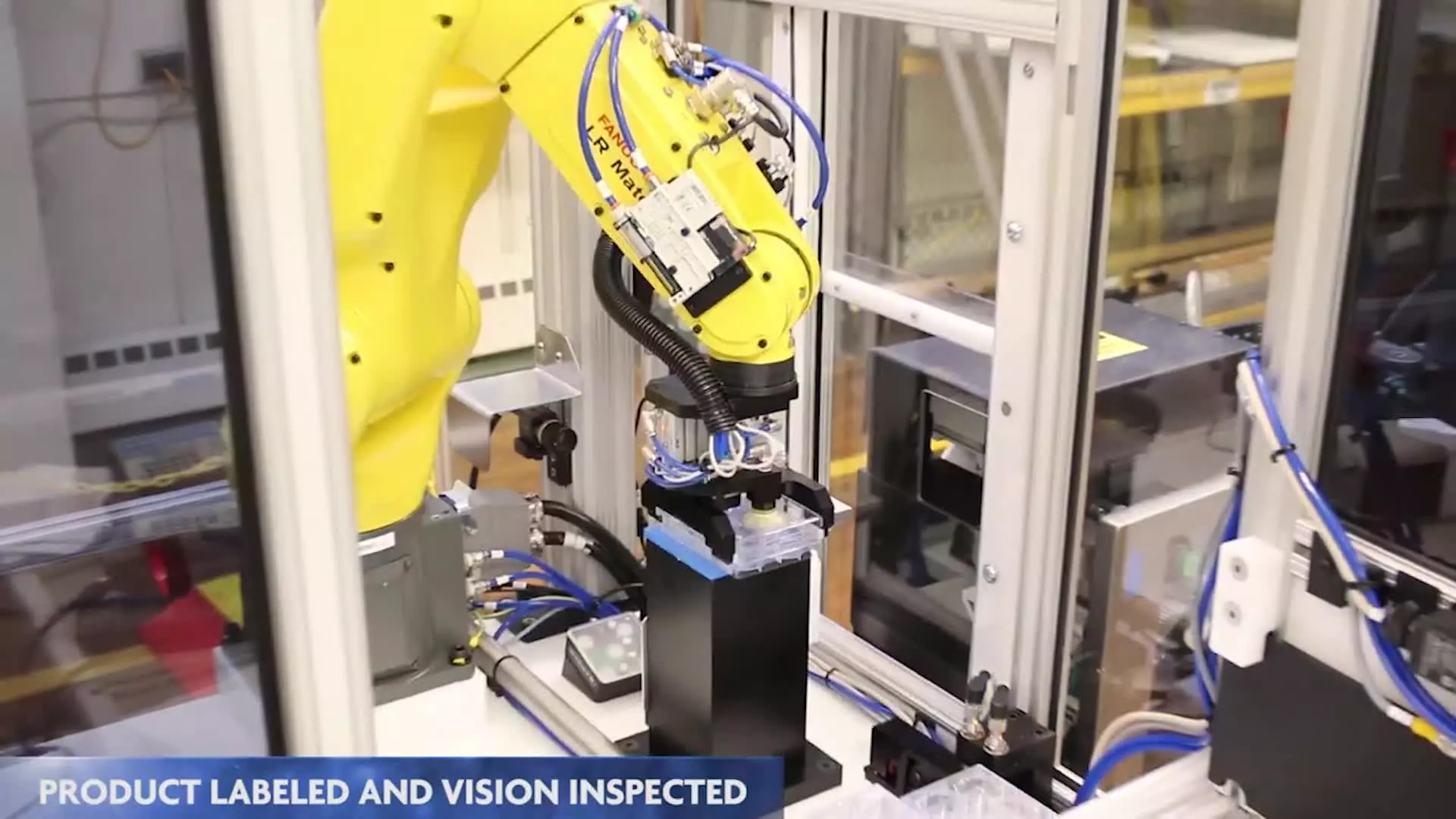

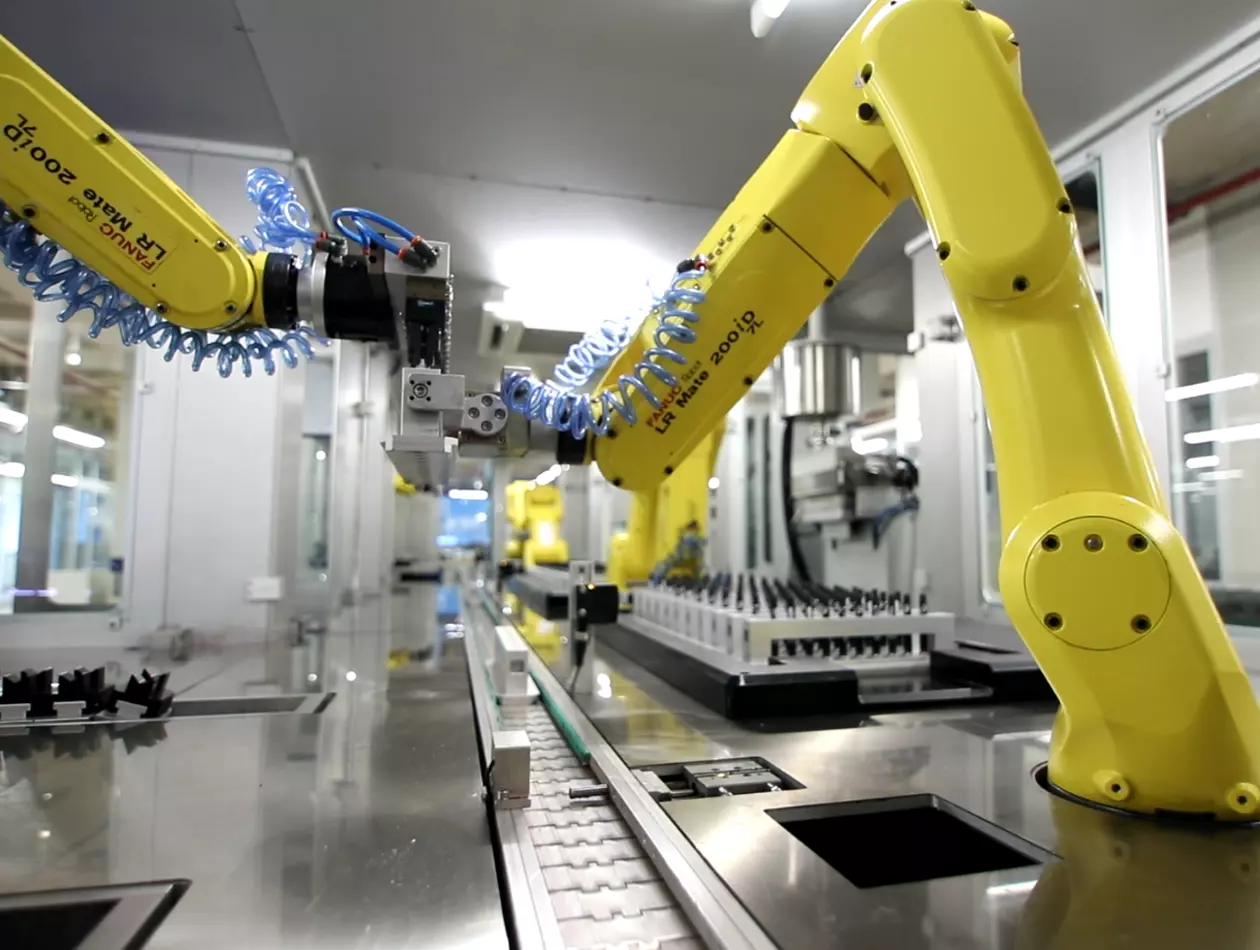

Fully Automated Assembly of Coffee Grinders

In the manufacture of popular household appliances such as coffee grinders, a number of prerequisites determine production success. For instance, only clearly structured, efficient and target-orientated processes will result in the required levels of production reliability. Achieving this ambition becomes significantly more realistic using automation, as market leader Eugster/Frismag AG can testify following its adoption of 14 FANUC LR Mate industrial robots and FANUC ZDT (Zero Down Time), which now enable the continuous automated assembly of a coffee grinder every 7 seconds.

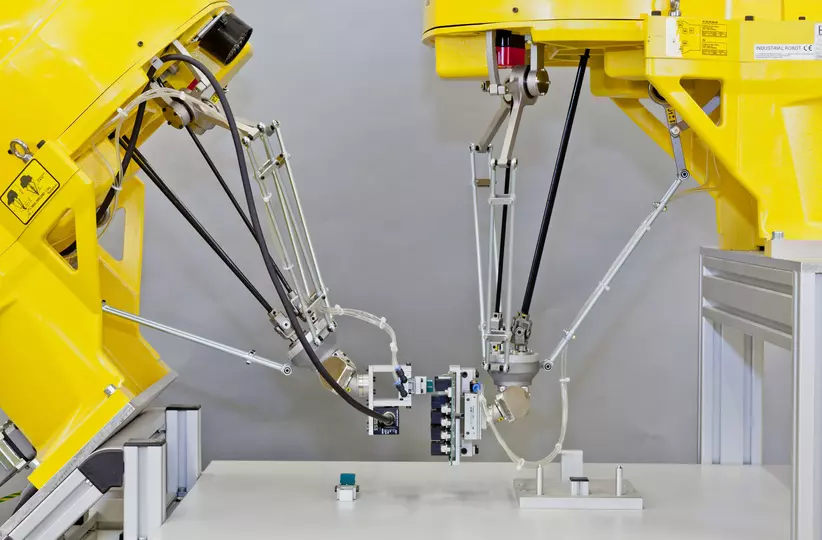

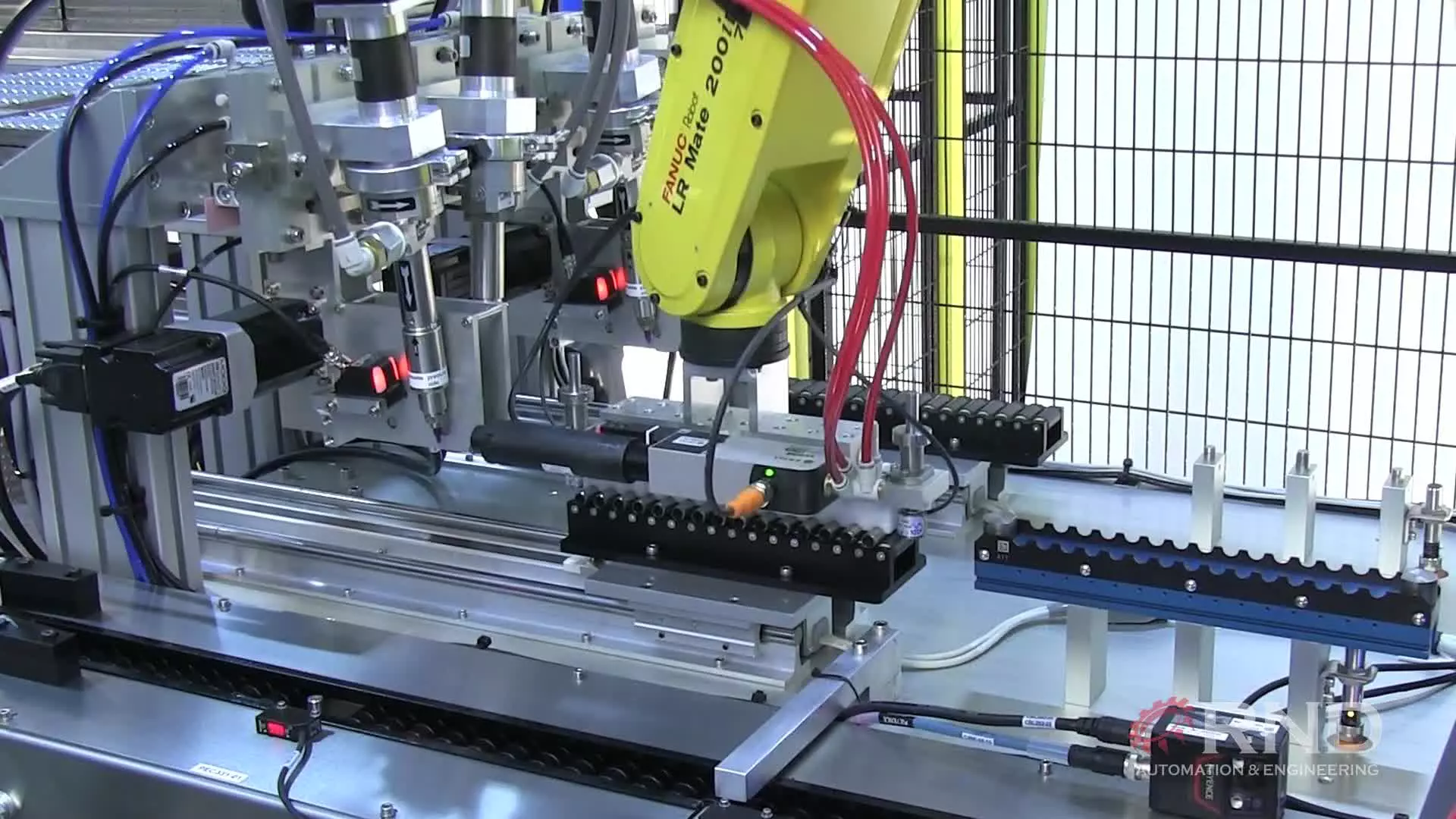

Assembly Order Picking with Two Robots on a 13 Metre Traversing Axis

Automating a production line can be done flexibly and in a small space. Customised solutions and safety software functions are a key element for successful implementation.

Proizvajalec kozmetike vidi lepoto avtomatizacije FANUC

Podjetje Erkul Cosmetics v Turčiji izkorišča številne prednosti kakovosti in učinkovitosti, ki jih zagotavljajo različni visoko zmogljivi izdelki FANUC za avtomatizacijo. To hitro rastoče kozmetično podjetje želi postaviti merila za proizvodnjo v svojem sektorju, pri čemer ga podpirajo konkurenčne prednosti, ki jih zagotavljajo rešitve FANUC.

Spremenite svojo industrijo z industrijskimi roboti FANUC

Avtomobilska industrija

Vesoljska industrija

Medicina

Električna vozila

Vse panoge

Preberite več o naših neskončnih možnostih

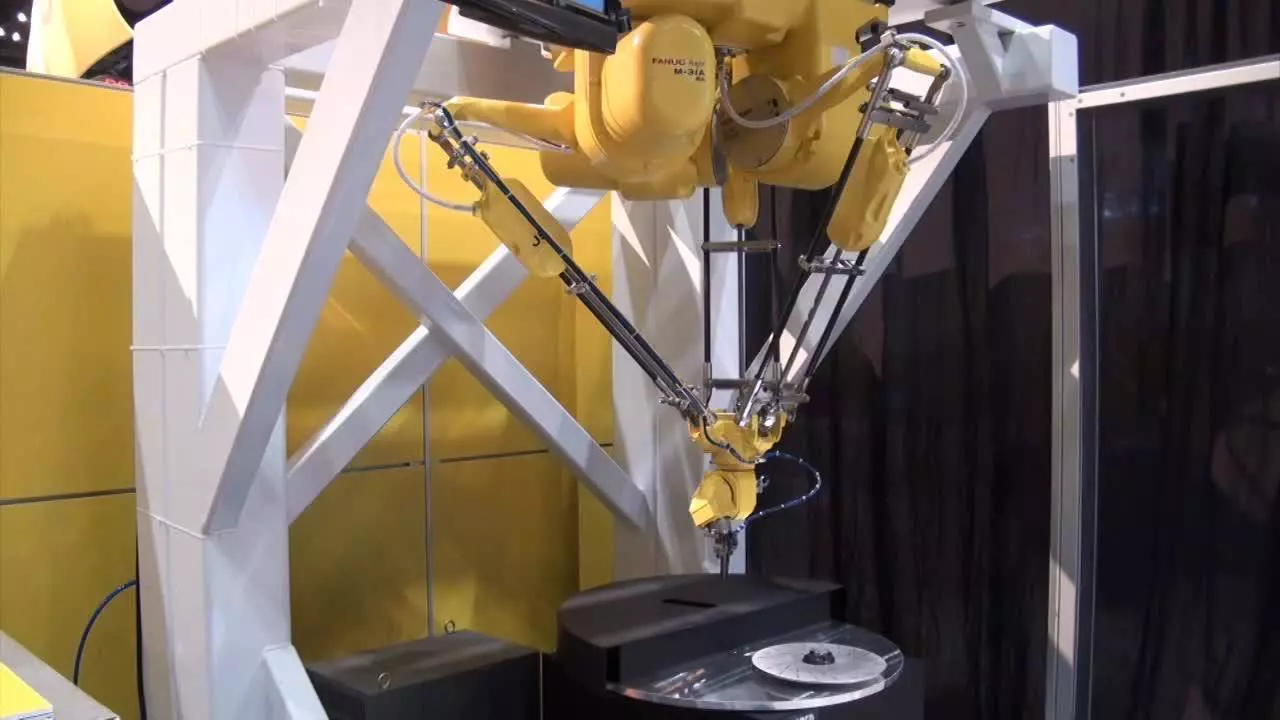

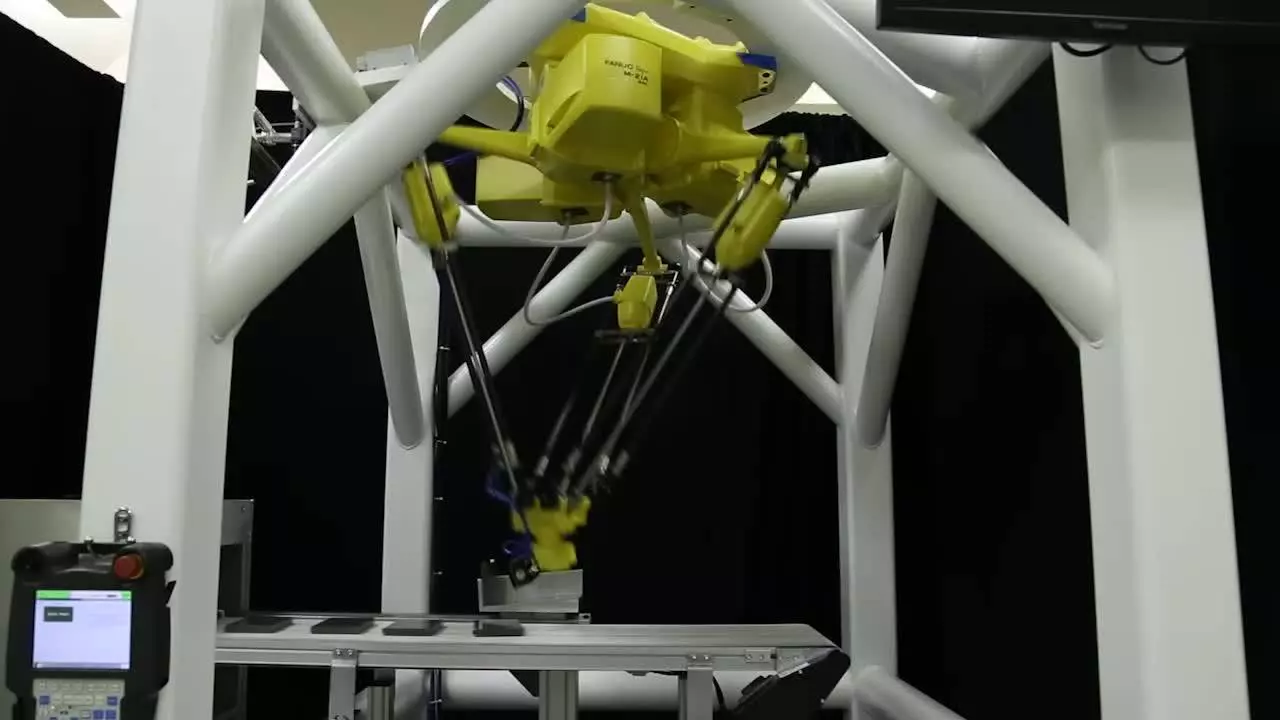

Šestosni robot FANUC M-3iA Delta sestavi ventilator

Robot FANUC M-1iA - sestava obeska za ključe

Robot FANUC M-1iA - električni priključek

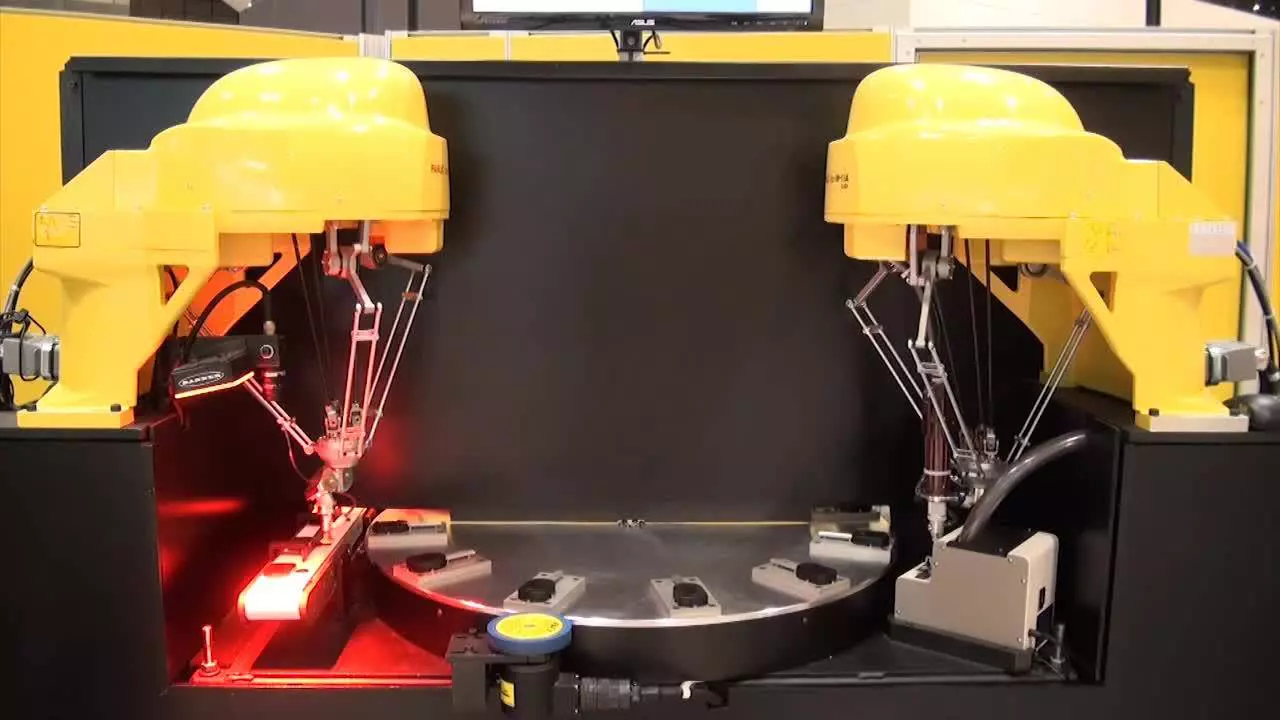

Robot FANUC M-2iA/3AL sestavlja celice avtomobilske baterije z vizualnim sledenjem črte

Sestavni sklop baterijskega paketa za robot FANUC SCARA SR-3iA

Mobilni sodelujoči robot - FANUC CR-7iA/L uporablja AGV za premikanje med postajami za montažo ro...

Naše rešitve za druge aplikacije

Povečajte učinkovitost, natančnost in produktivnost z rešitvami FANUC za različne aplikacije

Zagotavljamo rešitve za izboljšanje vaših proizvodnih procesov, od zelo natančnih robotov do pametne avtomatizacije.