Assembly Order Picking with Two Robots on a 13 Metre Traversing Axis

Get Inspired

W pełni zautomatyzowany montaż młynków do kawy

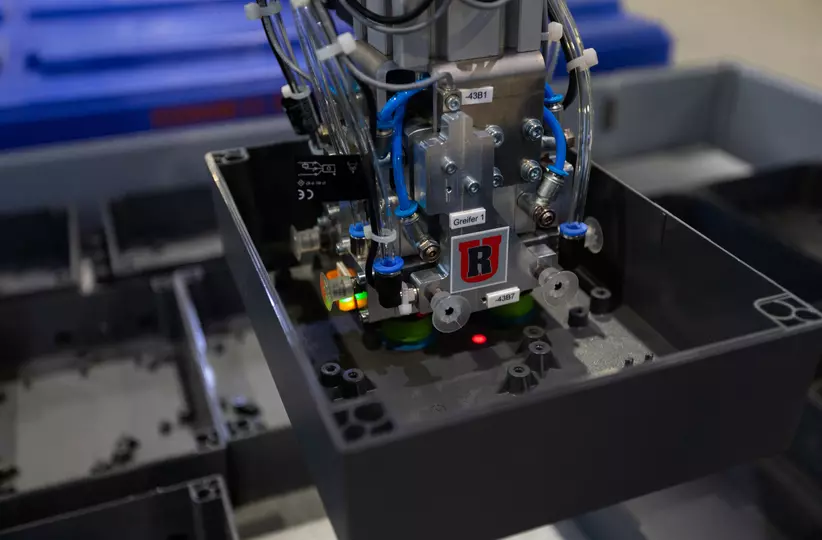

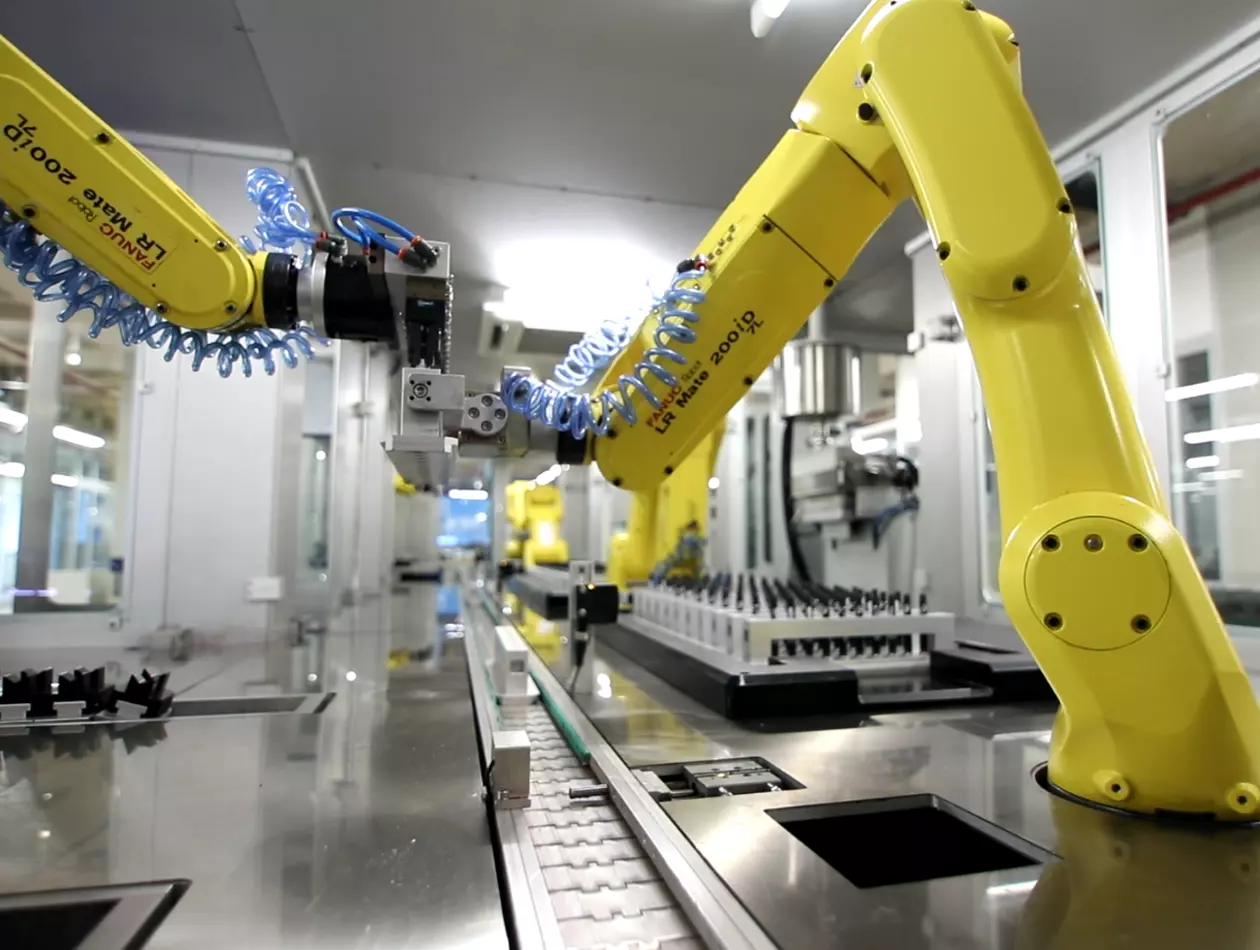

W produkcji popularnych urządzeń gospodarstwa domowego, takich jak młynki do kawy, o sukcesie decyduje szereg kluczowych czynników. Tylko jasno zorganizowane, wydajne i ukierunkowane na cel procesy mogą zapewnić wymaganą niezawodność produkcji. Osiągnięcie takiego poziomu jest znacznie bardziej realne dzięki automatyzacji – co potwierdza Eugster/Frismag AG, lider rynku, który wdrożył 14 przemysłowych robotów FANUC LR Mate oraz system FANUC ZDT (Zero Down Time). Dzięki temu firma może dziś automatycznie montować jeden młynek do kawy co 7 sekund, w sposób ciągły i niezawodny.

Producent kosmetyków dostrzega piękno automatyzacji FANUC

Firma Erkul Cosmetics z Turcji odnosi liczne korzyści w zakresie jakości i wydajności dzięki wysokowydajnym produktom automatyzacyjnym marki FANUC. To dynamicznie rozwijające się przedsiębiorstwo z branży kosmetycznej dąży do ustalenia nowych standardów produkcji w swoim sektorze, wykorzystując przewagi konkurencyjne, jakie oferują rozwiązania FANUC.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Obsługa materiałów

Montaż