Keramik

FANUC Robots Extend the Benefits of Stretch Hood System

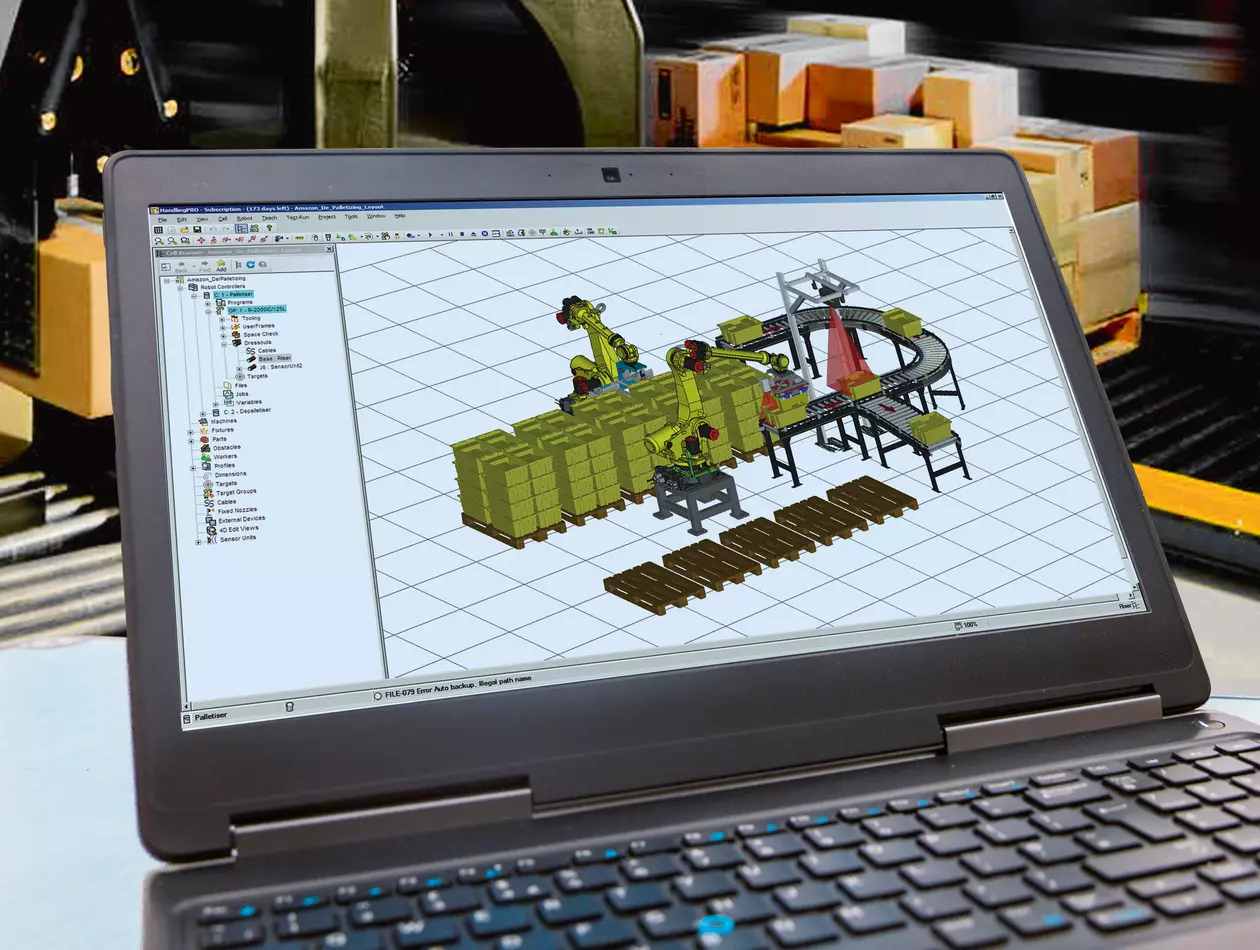

Keramik Makina, a FANUC system integrator, combined palletising and shrink hood systems with FANUC robots to form powerful end-of-line solutions at the paint factory of Polisan Kansai in Türkiye.

Megosztás

FANUC M-410𝑖C robots are purpose-designed for palletising operations.

Dedicated kinematics facilitate the best possible level of palletising efficiency.

M-410𝑖C robots can handle a large gripper and heavy payload at maximum speed.

FANUC M-410𝑖C robots offer multiple palletising positions for increased throughput.

Get Inspired

SIMLOGIC

Robotok a tejtermelésben

A robotok számára gyerekjáték az igénybevételt jelentő raklaprakodási feladatok elvégzése. Az összetett alkalmazások esetében az átgondolt fejlesztés és tervezés biztosítja a termelés hatékonyságát és versenyképességét.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Raklapozás

A raklapozási folyamat automatizálása növelheti a műveletek biztonságát és hatékonyságát. Az opciók széles skálájából választhat, így megtalálja a különböző méretekhez, hasznos terhekhez, ciklusidőkhöz és pontossági igényekhez tökéletesen illeszkedő megoldást, miközben biztosíthatja, hogy termékeit a lehető legnagyobb gondossággal kezeljék.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.