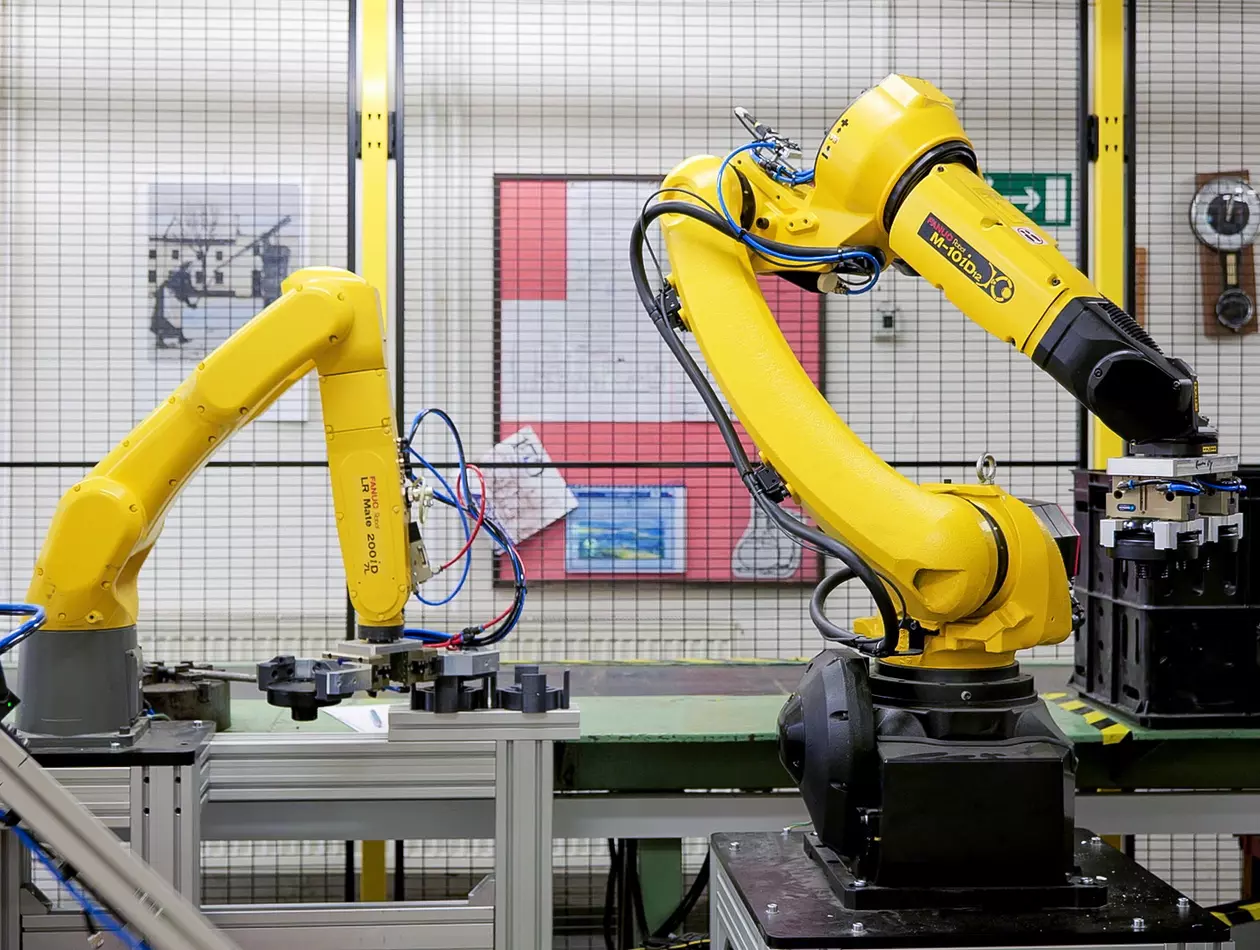

M-10𝑖D/12

Get Inspired

Get Inspiration from Other's Success

Automation is the Best Medicine at DEMO

A key player in the pharmaceutical industry, significantly improved its production capabilities with FANUC's automated solutions. By integrating FANUC robots, DEMO optimised the filling, packaging, and labeling processes, resulting in enhanced efficiency, accuracy, and overall productivity in their operations.

FANUC Robots Wash Away Inefficiency

Wäscherei Aschenbrenner GmbH struggled with a staff shortage for tasks like loading laundry folding machines. To solve this, they turned to Sewts GmbH, who provided the VELUM system. This system uses FANUC robots to prepare up to 700 towels per hour for folding. The automation has greatly improved efficiency, resolved the labour shortage, and reduced labour costs, promising a quick return on investment.

Robot Cell Established at Filter Manufacturer in Just 14 Days

When the COVID-19 pandemic swept across Europe, the need for effective particle filters to protect people from the virus was clear to see. FANUC, along with numerous other suppliers, sprang into action, in this case establishing a fully automated production cell to accelerate the manufacture of particle filters at the SIGMA Research & Development Institute in the Czech Republic.

Perfect Fit for Your Application

Machine Tending

Material Handling

Assembling

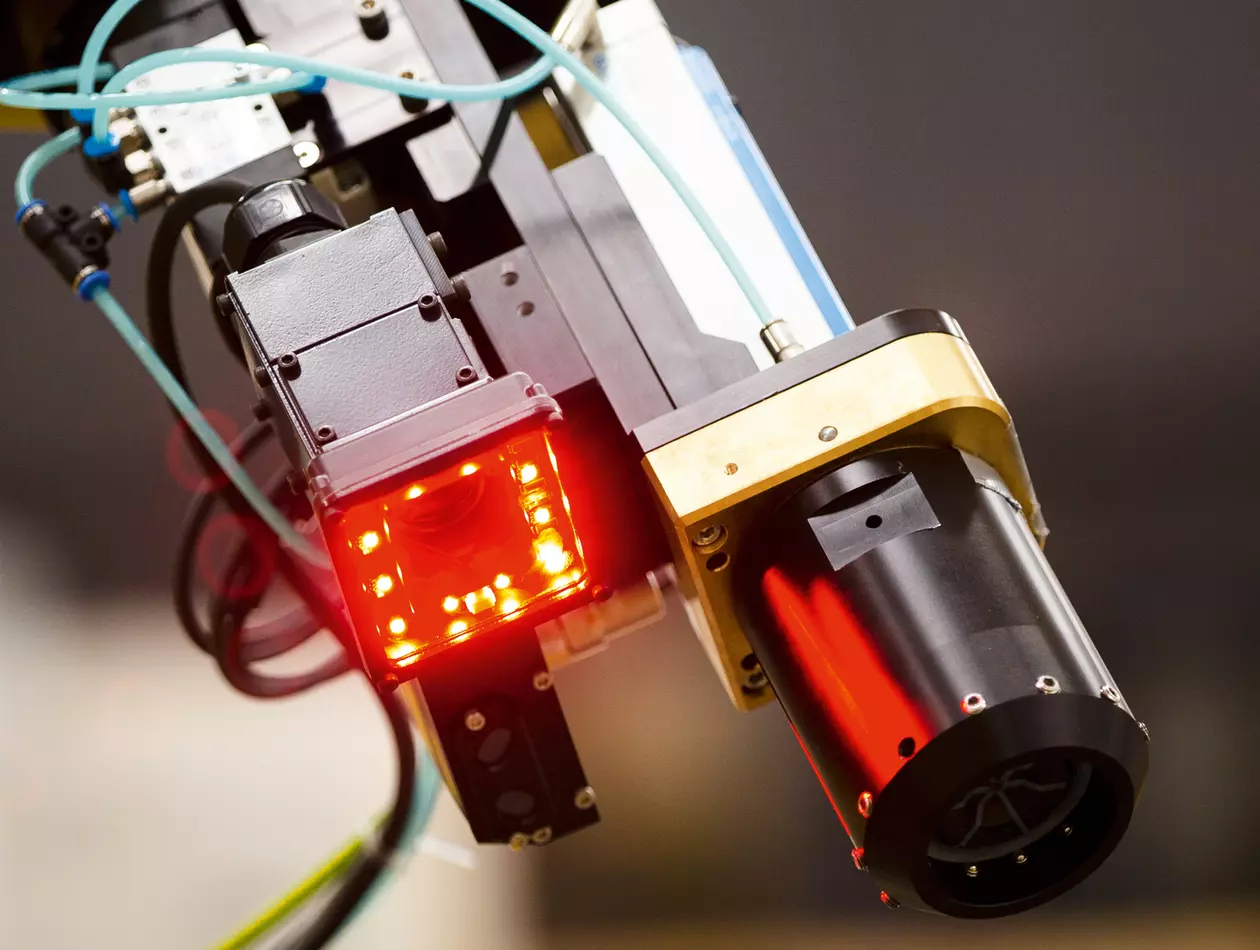

Vision Inspection

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

Robotics & Automation for the Automotive Industry

Electric Vehicles

Electronics

Food & Beverage

Robotics & Automation for the Medical Industry