Machine Tending

Streamline your Loading and Unloading Process with FANUC Machine Tending Robots

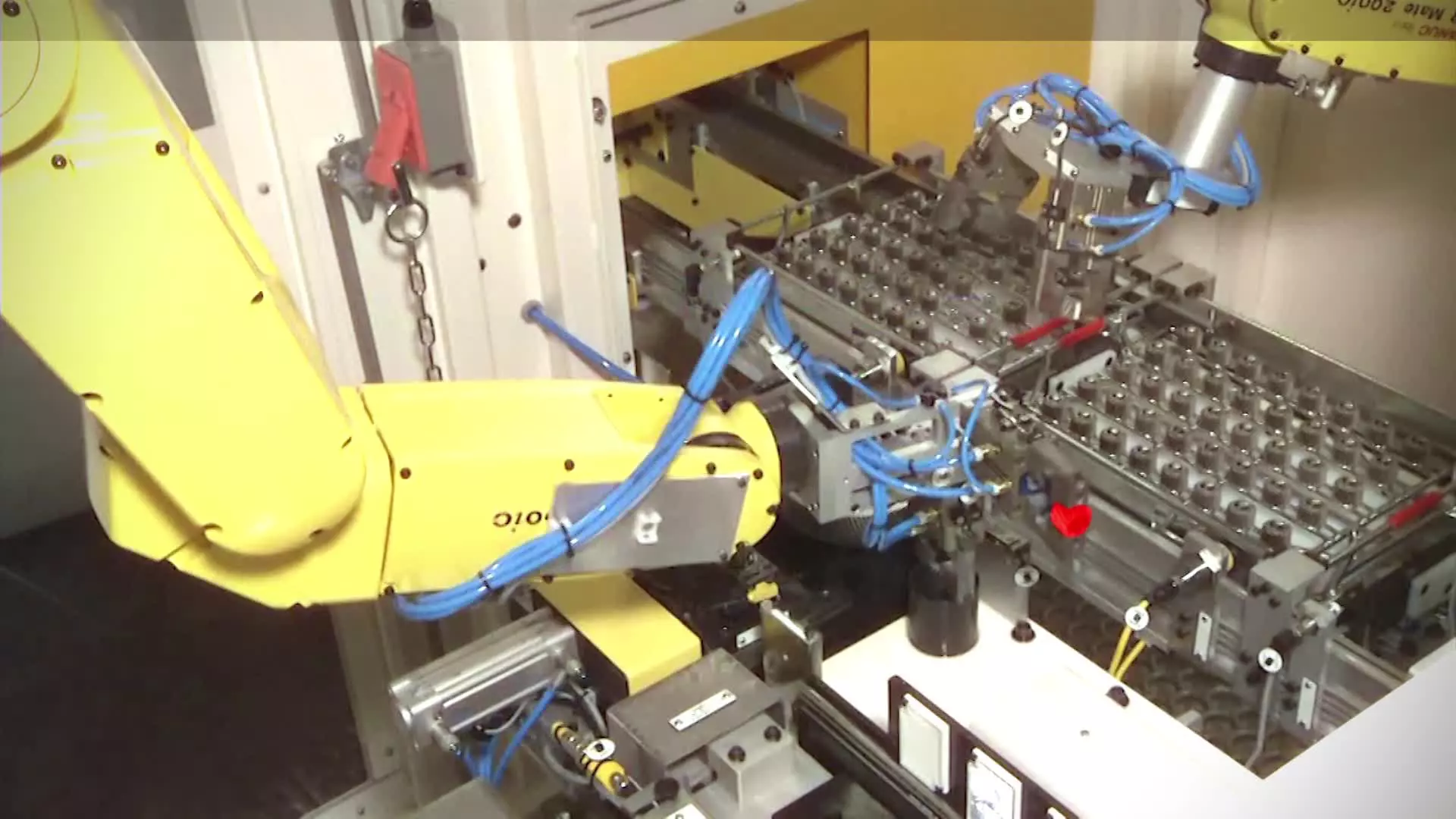

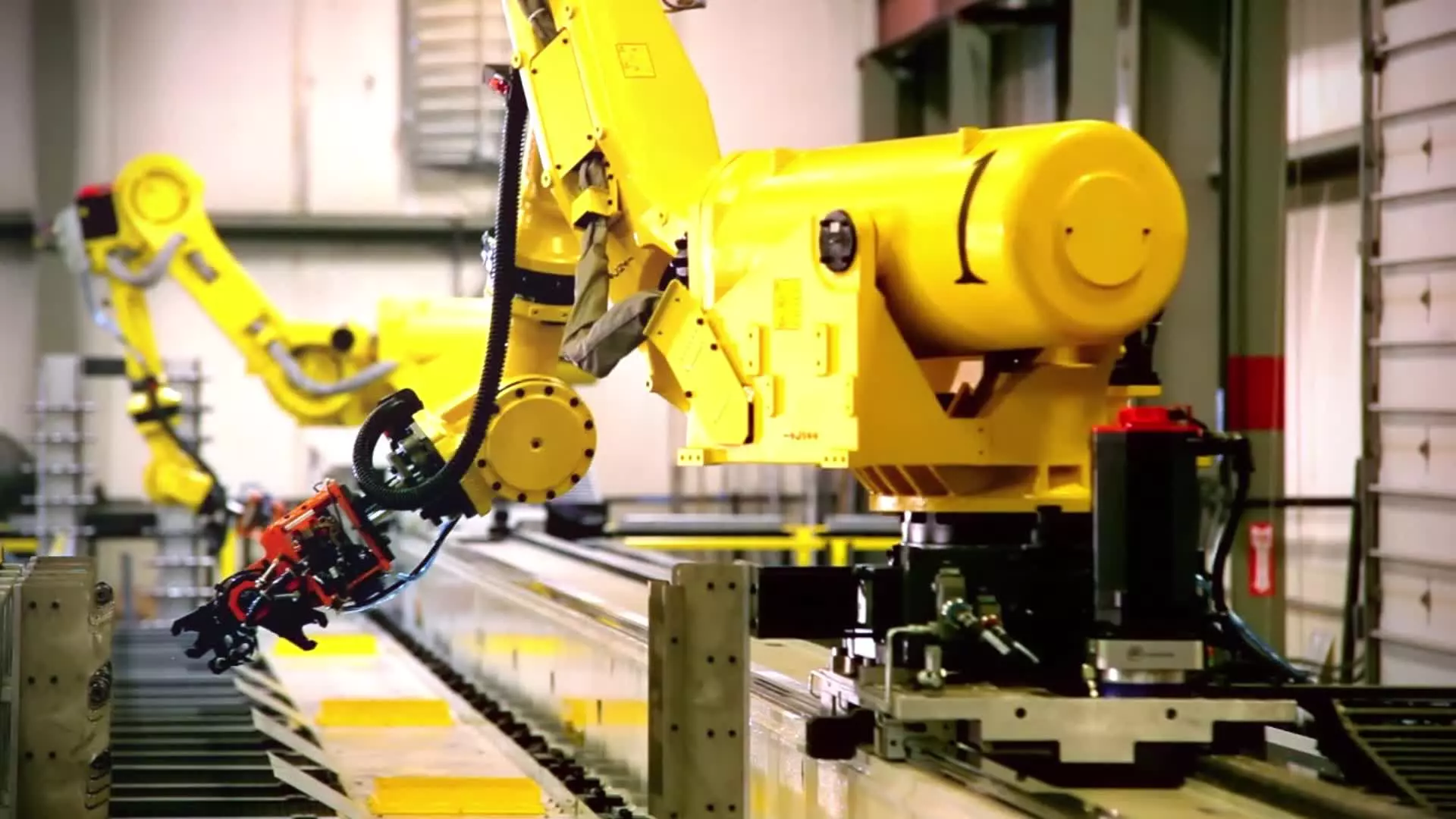

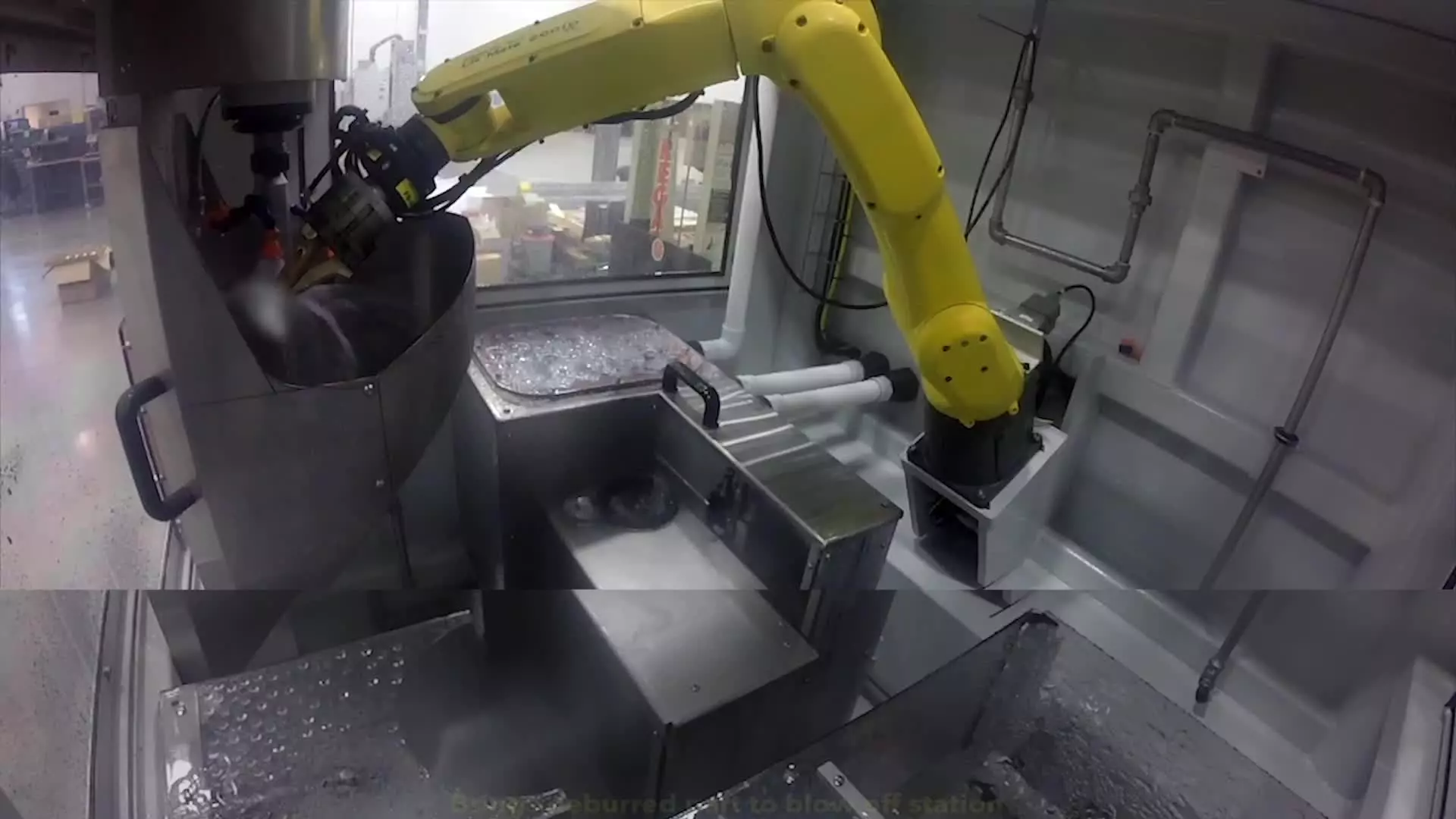

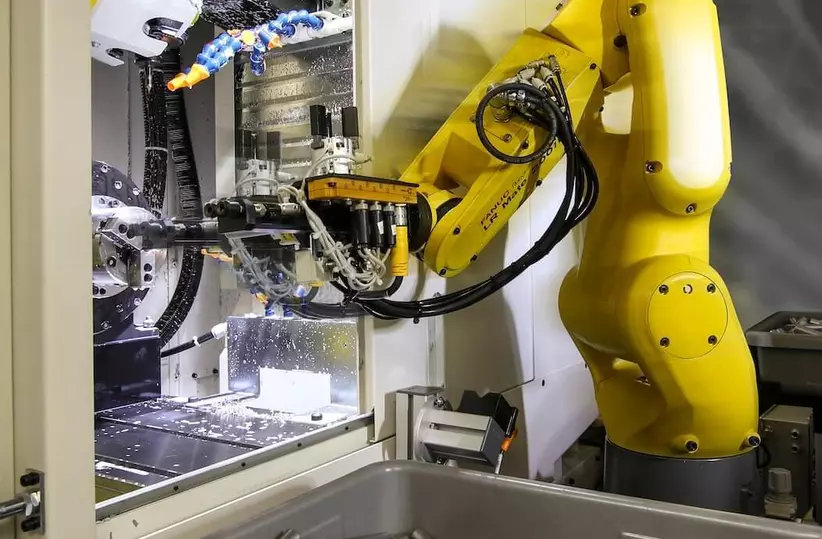

FANUC robots for machine tending automate the loading and unloading of machine tools, enhancing productivity and precision. Key models like the M-20 series and CRX series are designed for various industries, including automotive, aerospace, and electronics. These robots offer features such as intuitive guidance, high reliability, and advanced vision systems, making them ideal for improving efficiency and reducing downtime in manufacturing processes.

Get Inspired

Get Inspiration from Other's Success

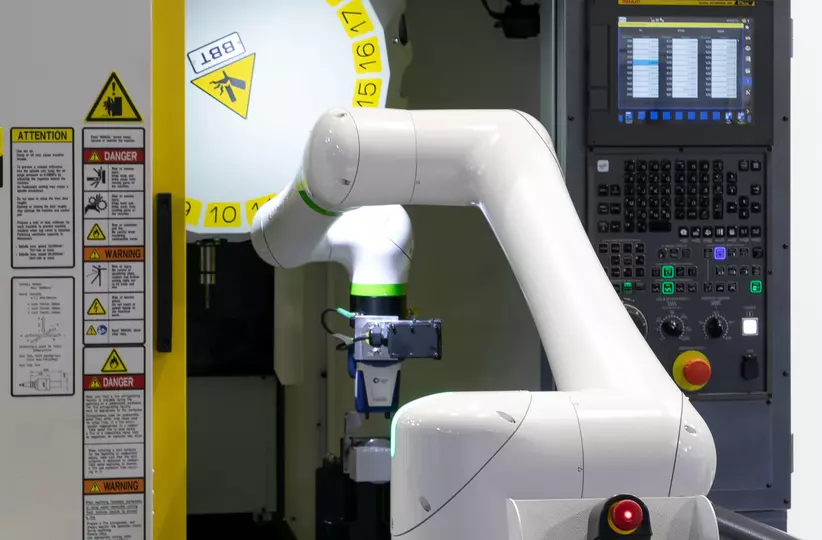

Man and Technology in Close Contact

The Cobot CRX-10𝑖A/L from FANUC makes it easy to produce reliably in the tightest of spaces. It has a compact design and significantly increases machine availability.

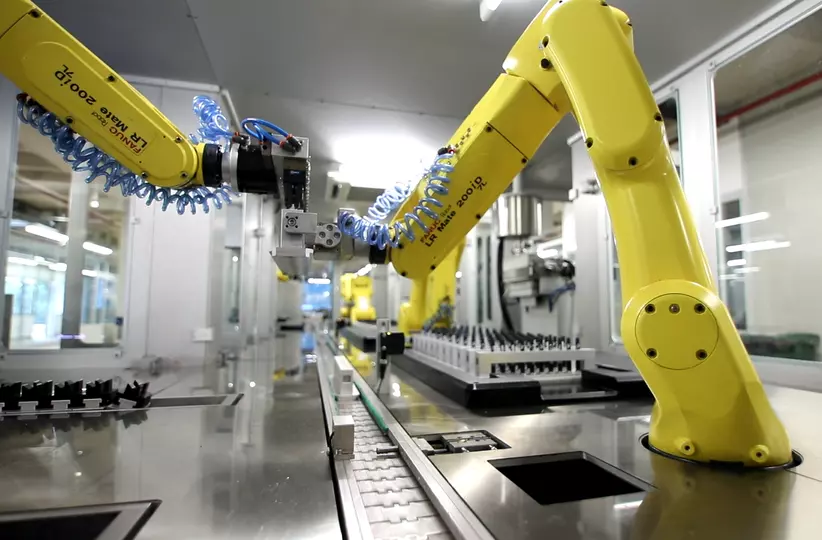

FANUC Provides Vision of the Future at ZAP

While machining can benefit greatly from the adoption of a machine-tending robot, the addition of 3D cameras introduces an extra level of intelligence that leads to autonomous production and particular benefits for manufacturers.

Automation is the Best Medicine at DEMO

A key player in the pharmaceutical industry, significantly improved its production capabilities with FANUC's automated solutions. By integrating FANUC robots, DEMO optimised the filling, packaging, and labeling processes, resulting in enhanced efficiency, accuracy, and overall productivity in their operations.

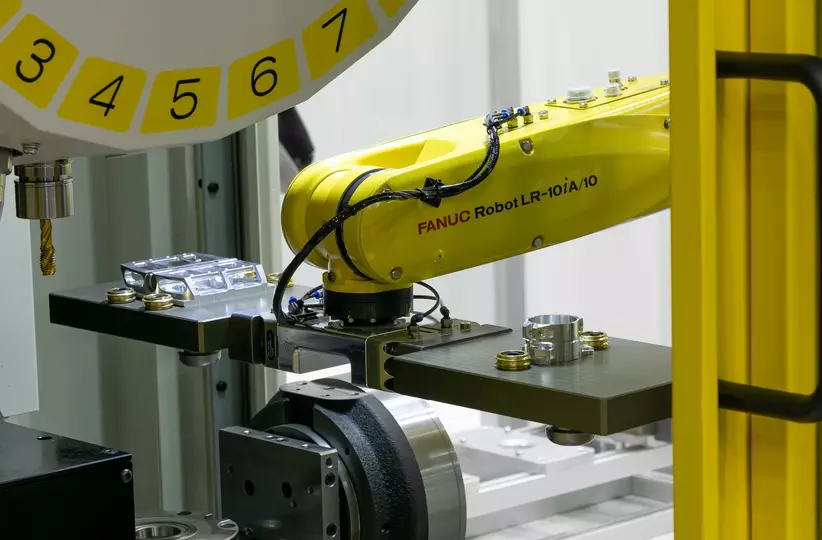

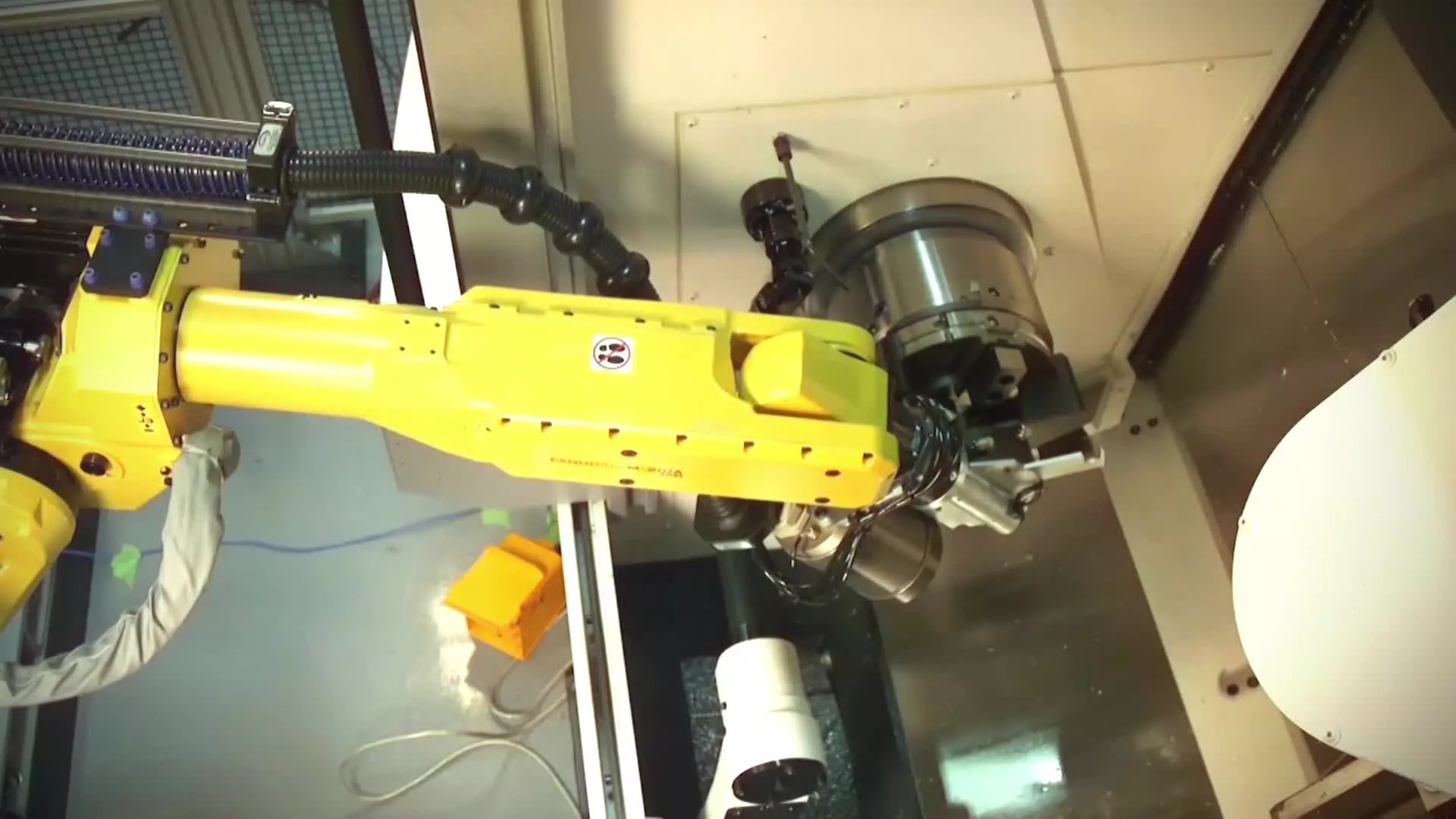

FANUC robots enable 24/7 CNC machining at RADMOT

Automated CNC machining cells comprising various machine tools and robots require astute design and integration. So why not simplify the process by turning to the world’s most prominent manufacturer of both CNC machine tools and robots: FANUC. That was precisely the strategy of RADMOT, a major Poland-based provider of machining services when it wanted to implement a new CNC milling cell involving three machining centres and two robots that could run unmanned 24 hours a day, 7 days a week – without any collisions between robots.

Transform your Industry with FANUC Machine Tending Robots

Automotive

Aerospace

Electronics

Medical

Pharmaceutical

Plastics

Electric Vehicles

All Industries

Learn More about our Infinite Possibilities

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.