Drôtové rezačky FANUC ROBOCUT

Pomocou nášho viacúčelového stroja na elektroerozívne obrábanie drôtom môžete vyrábať množstvo zložitých komponentov s bezkonkurenčnou presnosťou a rýchlosťou.

ROBOCUT Overview Brochure

Discover the complete product range

Inšpirujte sa úspechom iných

EUROEDIL

Spoločnosť EUROEDIL dosiahla vyššie rezné rýchlosti a výrobnú kapacitu so strojmi FANUC

S novými strojmi FANUC v areáli spoločnosti EUROEDIL sa zvýšila rýchlosť rezania a výrobná kapacita, aby sa splnili rastúci dopyt zákazníkov. Okrem toho sa výrazne zvýšila presnosť a precíznosť výroby výsekových nástrojov.

Perfektné prispôsobenie pre vašu aplikáciu

Rezanie drôtom EDM

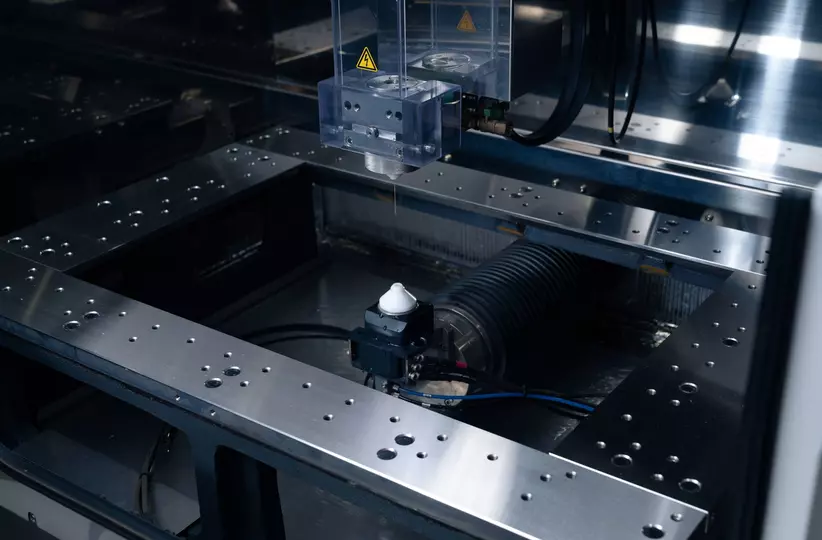

Elektroerozívne obrábanie drôtom (EDM) je presný výrobný proces, ktorý využíva tenký elektricky nabitý drôt na rezanie zložitých tvarov a kontúr v tvrdých kovoch a vodivých materiáloch. Drôt generuje sériu rýchlych elektrických výbojov, ktoré erodujú materiál s mimoriadnou presnosťou bez použitia mechanickej sily. Táto bezkontaktná metóda umožňuje výrobu veľmi detailných, zložitých dielov s vynikajúcou povrchovou úpravou, vďaka čomu je nevyhnutná pre priemyselné odvetvia, ktoré vyžadujú presné obrábanie, ako je letecký priemysel, medicína a výroba foriem.

Riešenia na mieru pre vaše odvetvie

Komplexné obrábanie pre letecký priemysel

Optimalizujte výrobné procesy v leteckom a kozmickom priemysle s najmodernejšími komplexnými riešeniami na obrábanie od spoločnosti FANUC!

Komplexné obrábanie pre automobilový priemysel

Presnosť a efektivita vo výrobe automobilov!