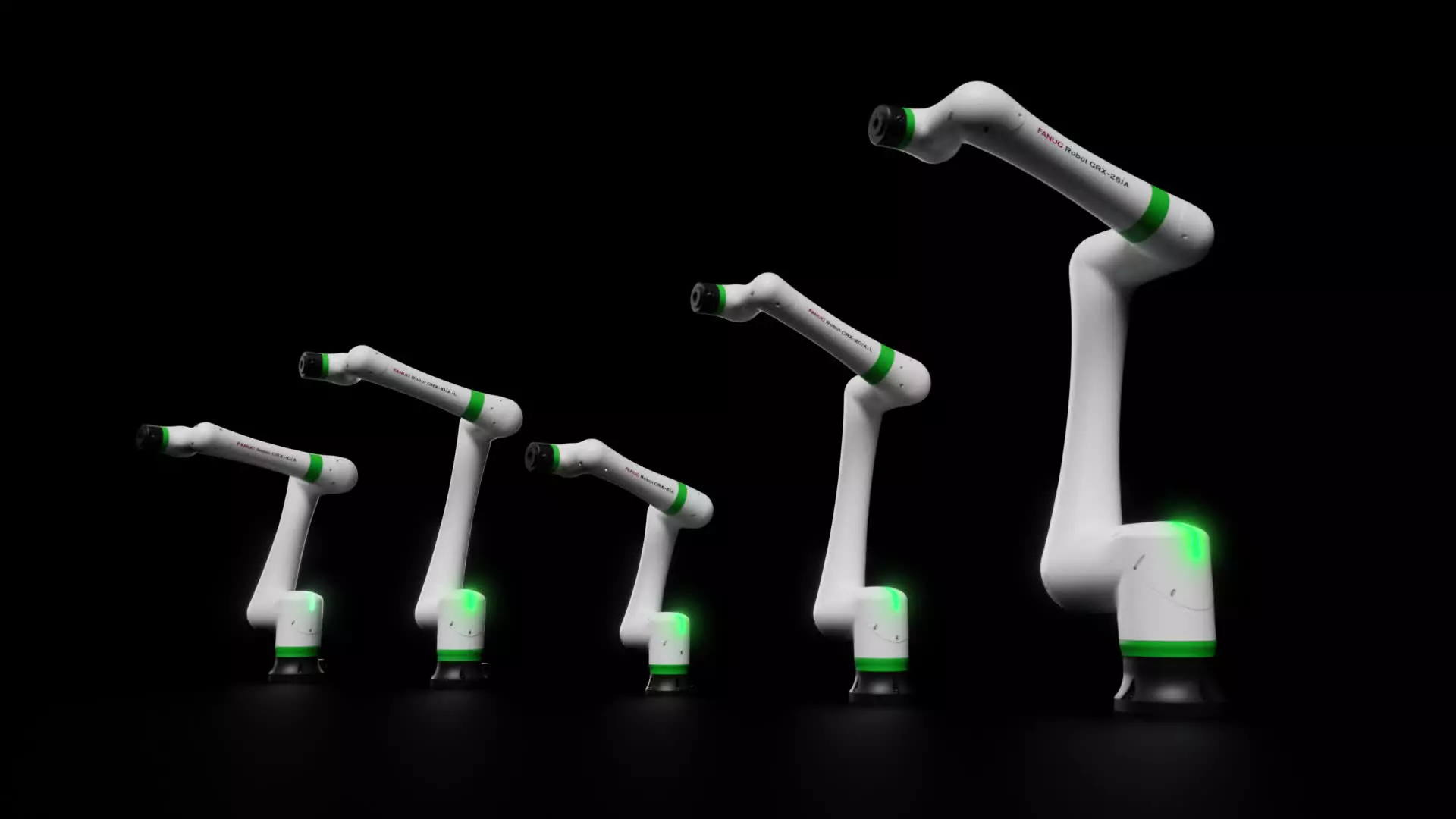

CRX-10𝑖A/L

Get Inspired

Get Inspiration from Other's Success

Cooker Hood Manufacturer Extracts the Advantages of FANUC Robots

The co-operation between FANUC and extractor hood manufacturer Silverline, which started with a special automated bonding project in 2015, has led to a total of 17 robots working across the company’s factory in Turkey. FANUC regularly sees this kind of outcome, where taking the initial leap into robot investment leads to an almost immediate realisation that manufacturing can reach entirely new performance levels.

Leading Plastic Parts Producer Relies on Automated FANUC Solutions

All growing manufacturers need a reliable technology partner with innovative machines and solutions that can underpin success in the globally competitive market. Able to provide suitable testimony is Germany-based AKO Kunststoffe GmbH, a fourth-generation family-run injection moulding business that relies on around 30 FANUC ROBOSHOT all-electric injection moulding machines, including eight automated with FANUC industrial robots.

FANUC Cobot Helps GER4TECH Make its Move

Developing a new robot requires expertise, experience and often collaboration with partners who have specialised knowledge in specific technology fields. So, when GER4TECH wanted a specialist in collaborative robots to bring advanced capabilities to its new autonomous mobile robot (AMR), the company reached out to FANUC.

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

Man and Technology in Close Contact

The Cobot CRX-10𝑖A/L from FANUC makes it easy to produce reliably in the tightest of spaces. It has a compact design and significantly increases machine availability.

Perfect Fit for Your Application

Arc Welding

Machine Tending

Material Handling

Assembling

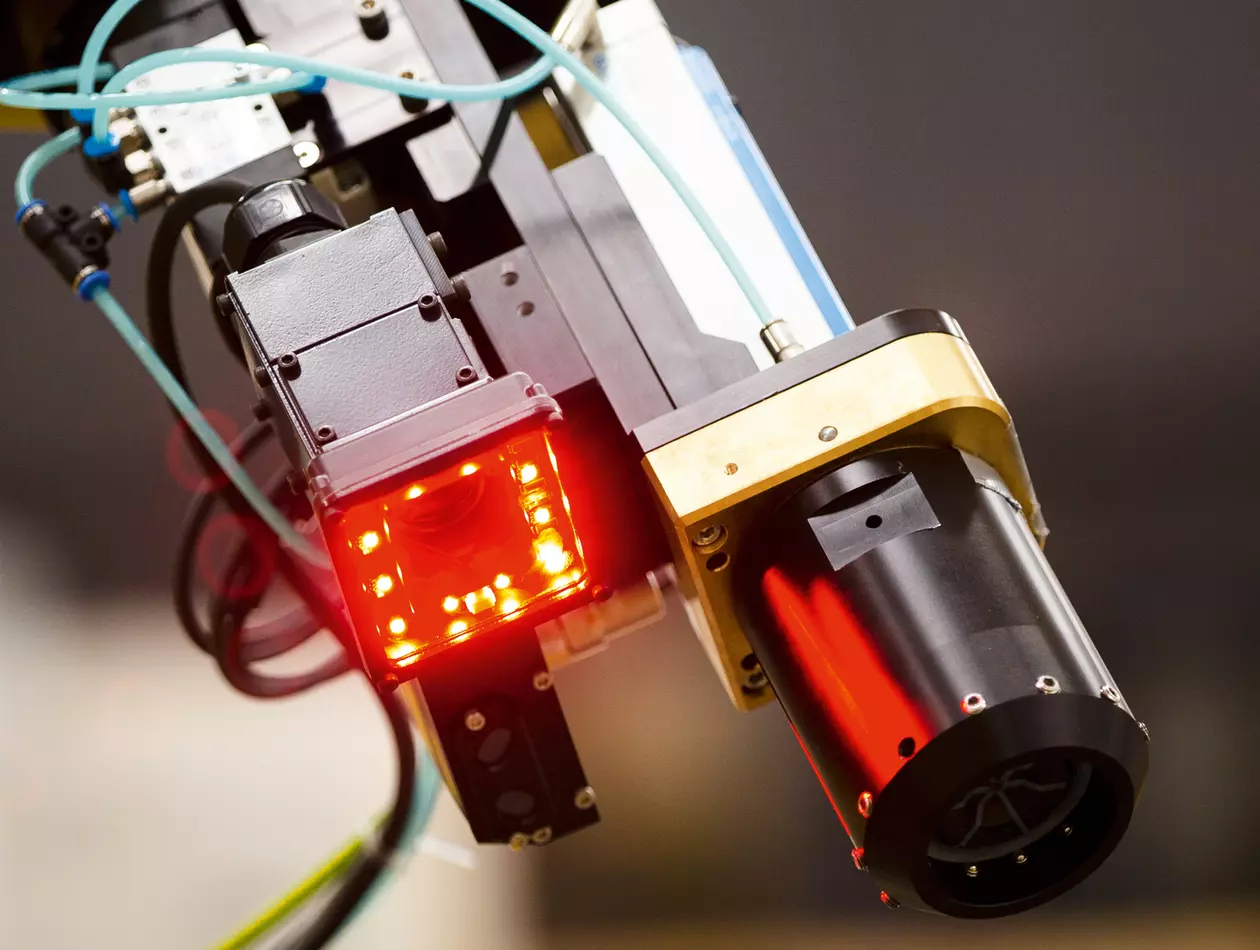

Vision Inspection

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

Robotics & Automation for the Automotive Industry

Electric Vehicles

Electronics

Food & Beverage

Robotics & Automation for the Medical Industry