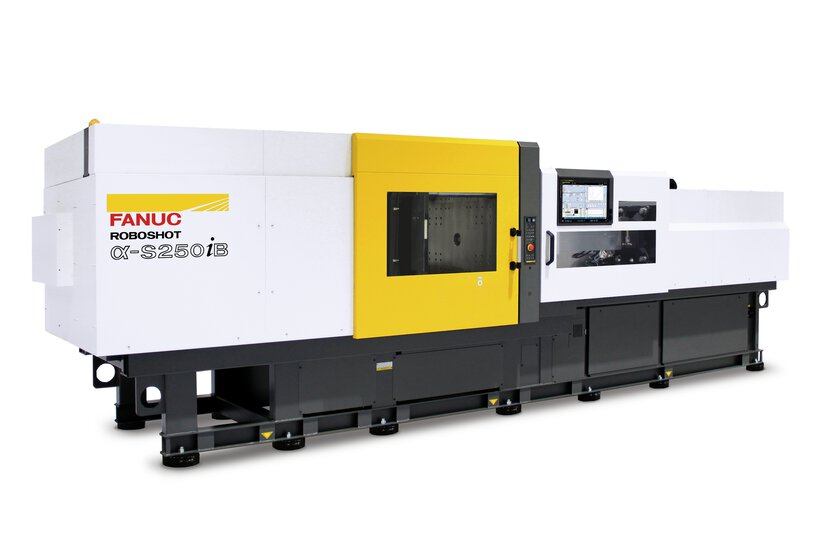

ROBOSHOT Electric Injection Moulding Machines

The Future of Injection Moulding!

Ready to revolutionise your injection moulding? Join Andy Armstrong, Head of Sales ROBOSHOT Europe, as he unveils the game-changing new machine. Discover cutting-edge features like the powerful CNC control and intuitive touchscreen, plus unparalleled benefits like energy monitoring and production efficiency. Witness the machine's rock-solid hardware for unwavering reliability, precision, and speed. Watch now and transform your production!

Leading Plastic Parts Producer Relies on Automated FANUC Solutions

All growing manufacturers need a reliable technology partner with innovative machines and solutions that can underpin success in the globally competitive market. Able to provide suitable testimony is Germany-based AKO Kunststoffe GmbH, a fourth-generation family-run injection moulding business that relies on around 30 FANUC ROBOSHOT all-electric injection moulding machines, including eight automated with FANUC industrial robots.

Leading OEM Drives Energy Efficiency With FANUC ROBOSHOT Machines

Although electricity prices levelled off across 2023 and 2024 following huge spikes in 2020 and 2022, they are still significantly higher than pre-pandemic levels, with many experts predicting they may remain high for the rest of this decade and potentially beyond. The way for beleaguered manufacturers to fight back is to invest in energy-efficient machinery, just like the FANUC ROBOSHOT injection moulding machine.

TESY on the Road to Efficiency With ROBOSHOT

High production efficiency, low energy costs and noise emissions bundled with great technical support and service is what customers can expect from FANUC’s ROBOSHOT fully electric injection moulding machine.

Injection Moulding

Electronics