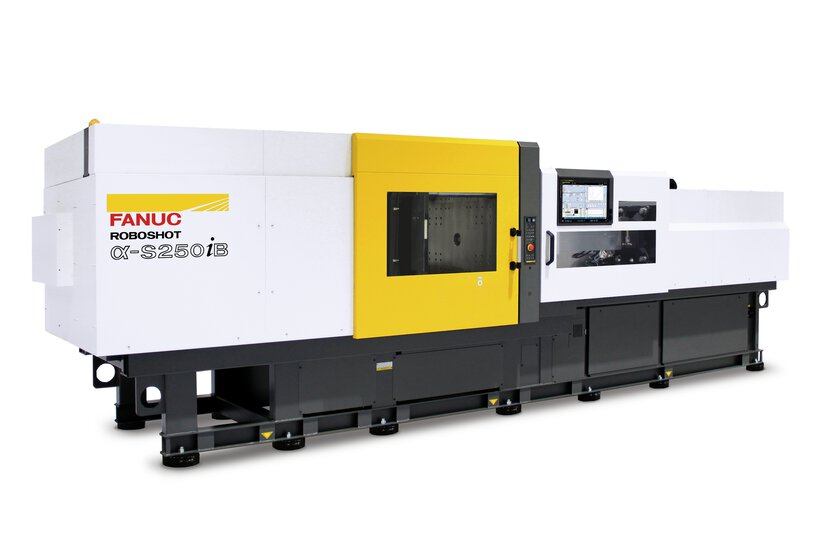

ROBOSHOT 𝛼-S250𝑖B

Get Inspired

Get Inspiration from Other's Success

Optimised Resources and Sustainable Moulding Thanks to FANUC

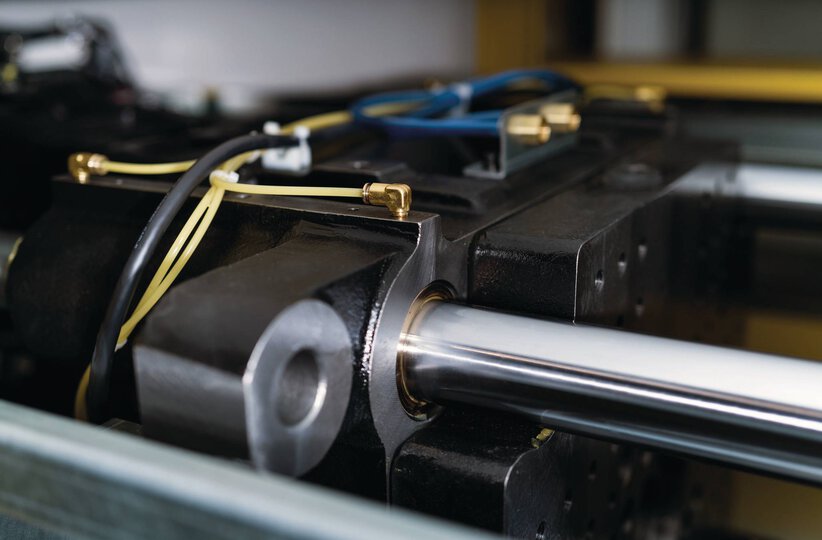

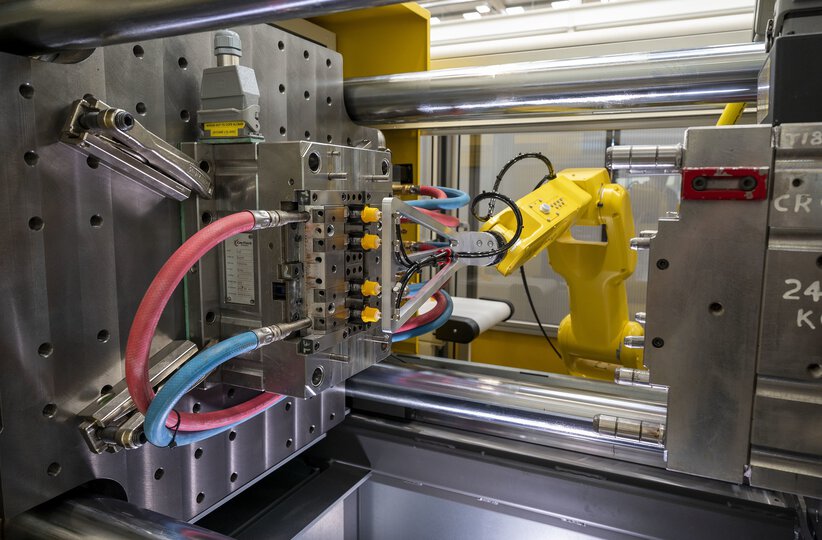

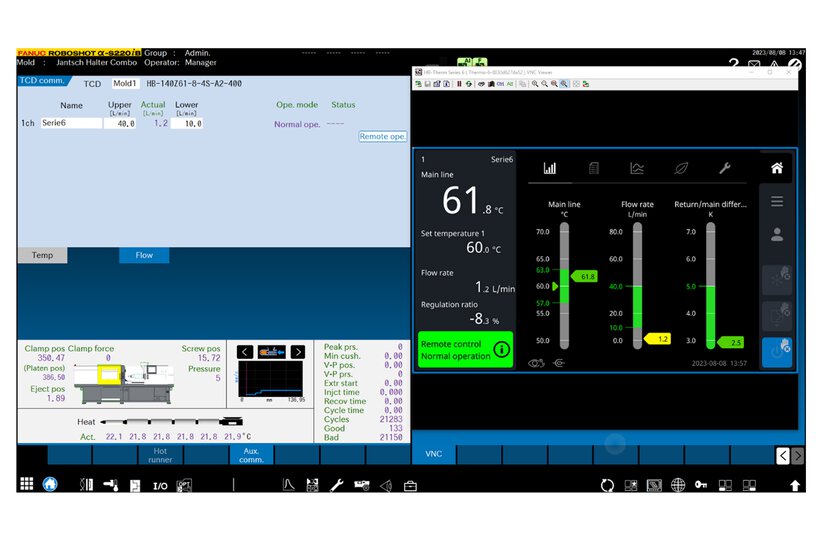

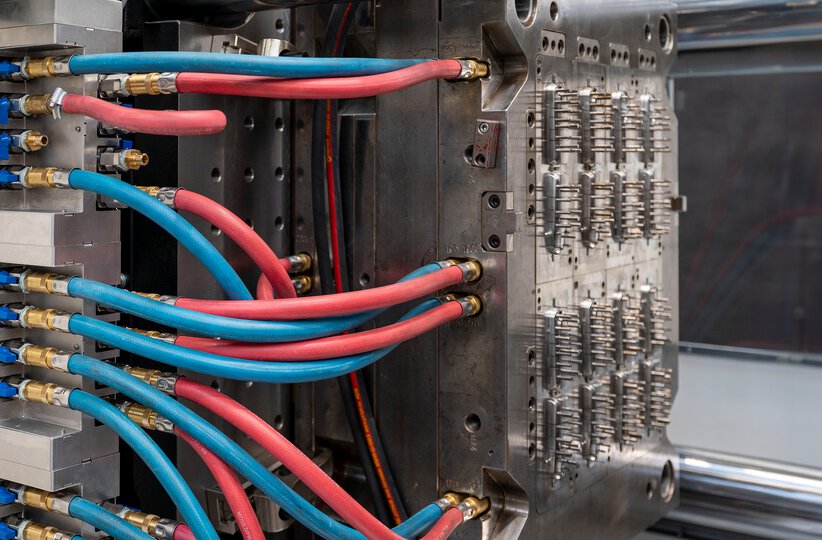

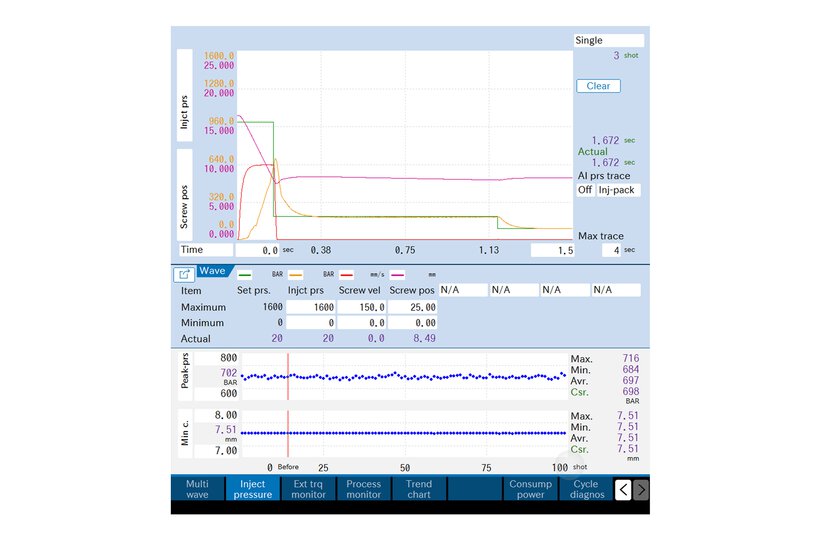

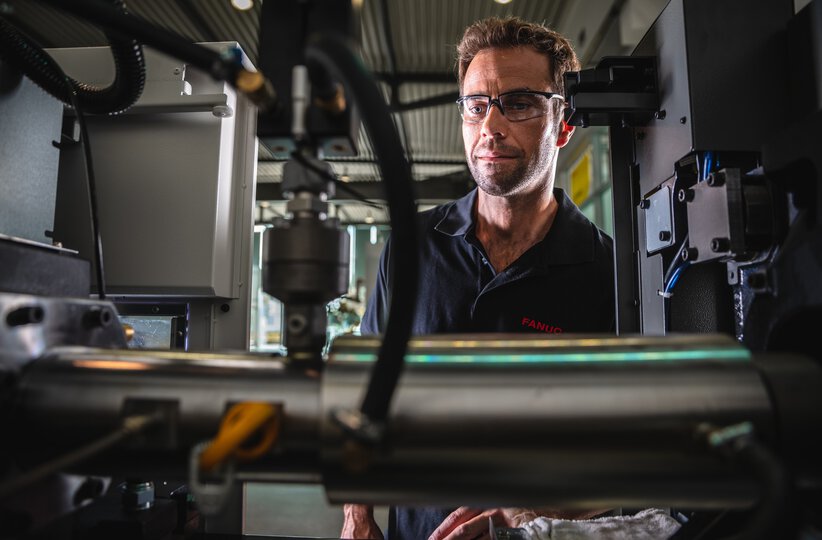

In the food packaging industry, production must be fast, reliable and clean. No wonder Poloplast chose FANUC's ROBOSHOT injection moulding machines. In addition to immediate efficiency improvements and energy savings, the advanced software features on the machines allow the company to further monitor and increase productivity while expanding its range of biodegradable products.

Injection Moulding Shop Shapes its Future with FANUC

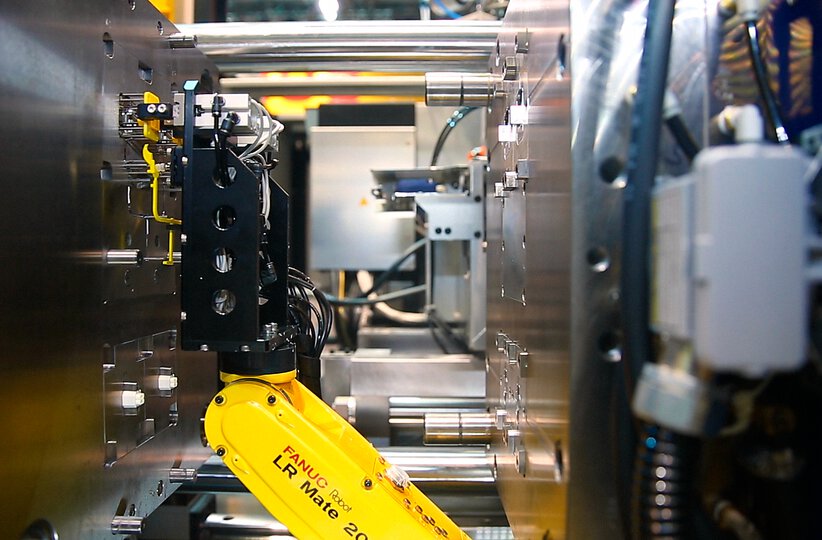

There are numerous plastic injection moulding machines available on the market, but most modern manufacturers seek a core set of key attributes based on flexibility, energy efficiency and performance. As a result, the highly capable FANUC ROBOSHOT, with its potential for rapid tool changes and all-electric low energy consumption, is a proven choice for any manufacturer of plastic products looking to become more competitive and gain market share. Among those able to provide testimony is Hungary-based Viskiplast.

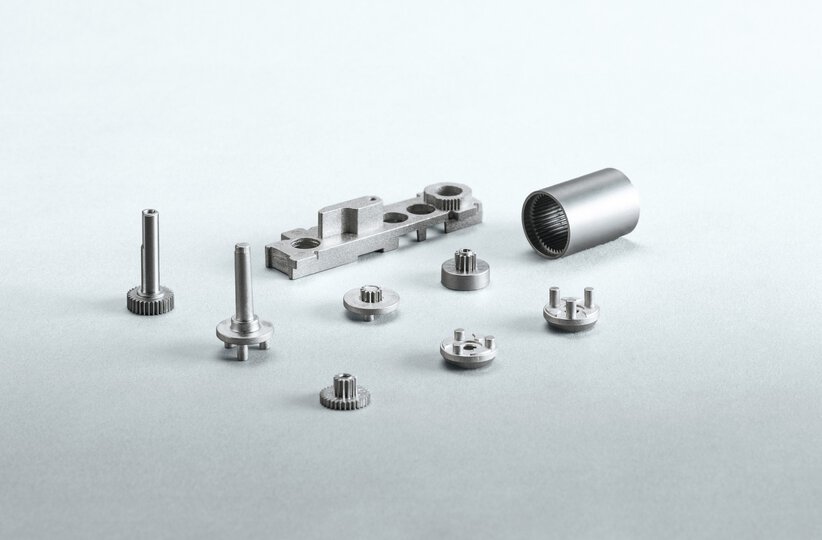

Perfect Fit for Your Application

Injection Moulding

Tailored Solutions for Your Industry

Food & Beverage

Electronics

Advanced Injection Moulding for the Aerospace Industry

Advanced Injection Moulding for the Automotive Industry

Advanced Injection Moulding for the Medical Industry