ROBOSHOT 𝛼-S220𝑖B

Share

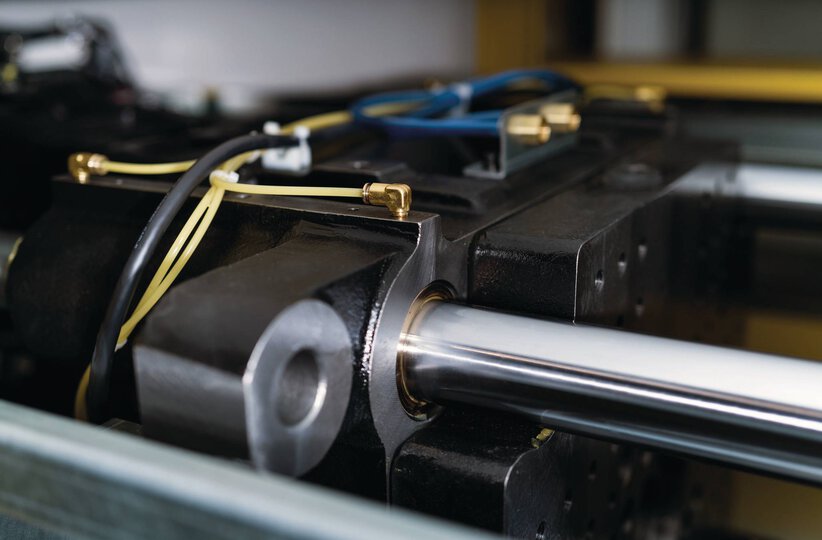

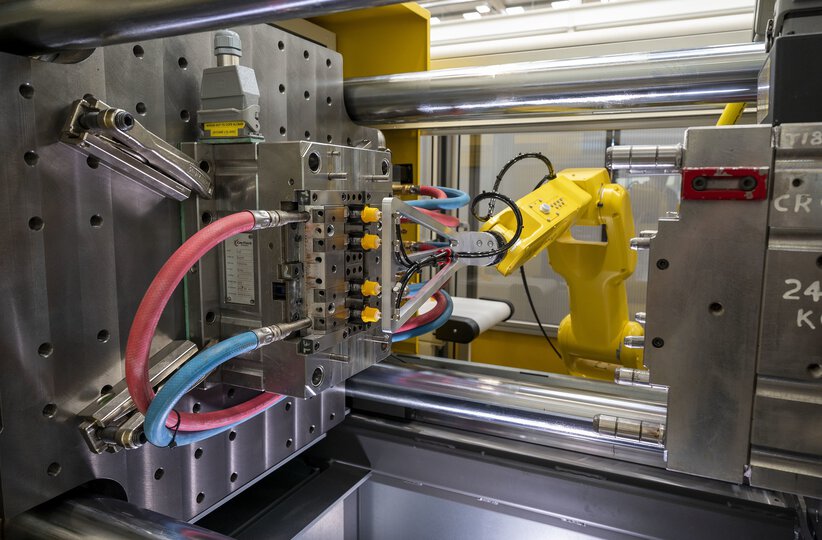

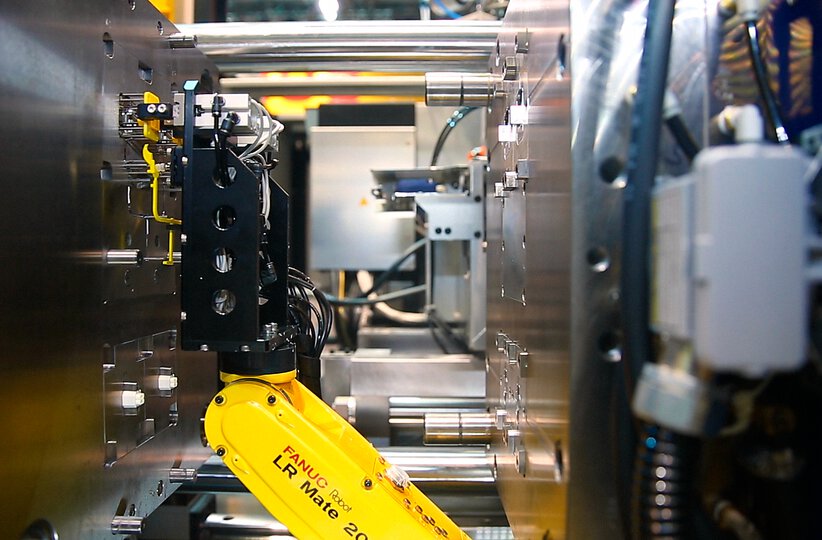

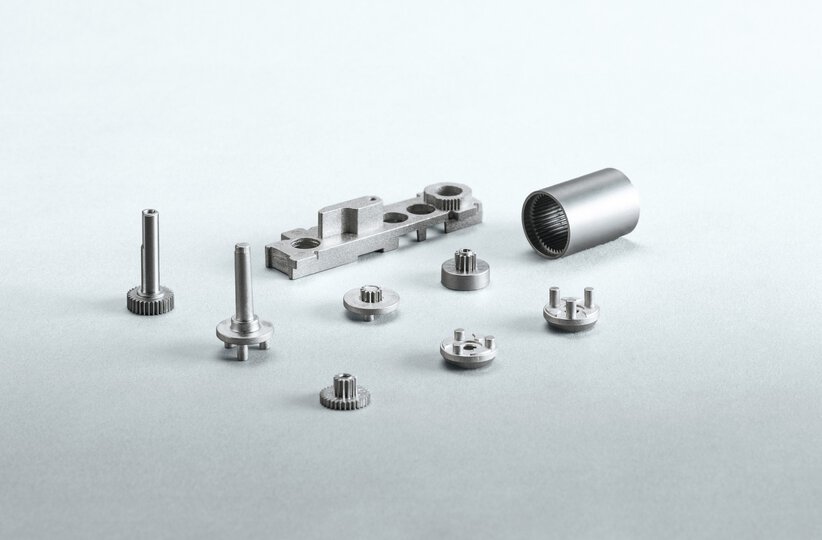

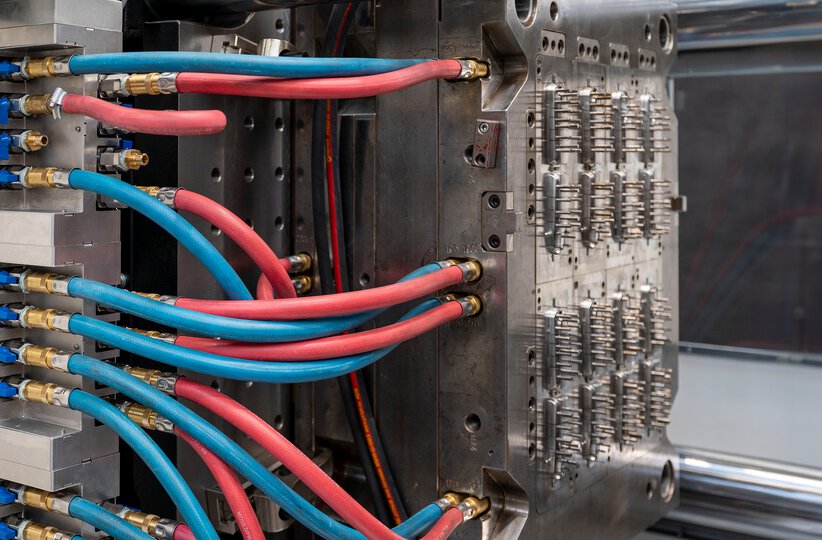

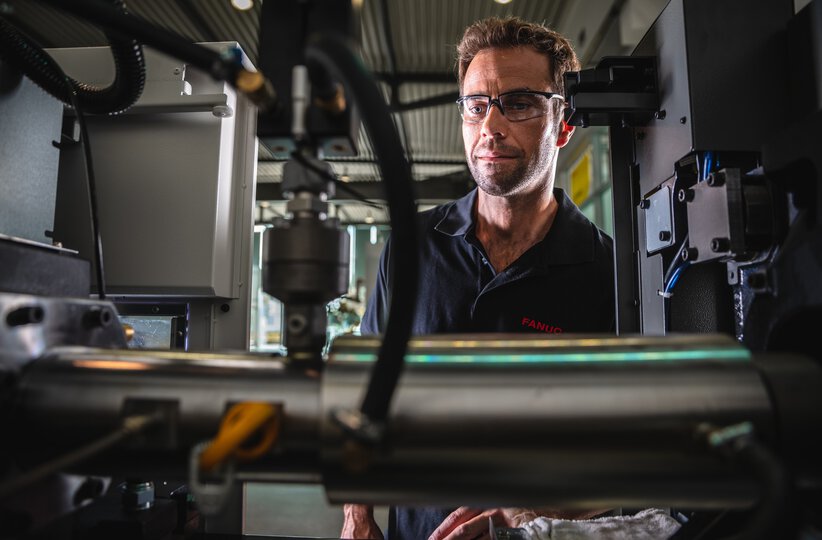

Designed to excel in connector businesses, automotive manufacturing, electronics production, medical device fabrication, and consumer goods manufacturing, this machine delivers consistent quality and precision. Its advanced 2K multi-component molding technology ensures unmatched flexibility, making it the preferred choice for all-rounder applications across a wide array of industries.

Tonnage

2200 kN | 220 tonf

Tie bar spacing, H×V

650x650 mm

Screw diameter (mm)

32, 36, 40, 44, 48, 52, 56 mm

Get Inspired

Get Inspiration from Other's Success

Erkul Cosmetics

Cosmetics Manufacturer Sees the Beauty of FANUC Automation

Erkul Cosmetics in Turkey benefits from a myriad of quality and efficiency benefits provided by various high-performance FANUC automation products. This fast-growing cosmetics enterprise is looking to set a benchmark for manufacturing in its sector, supported by the competitive gains that FANUC solutions provide.

Poloplast

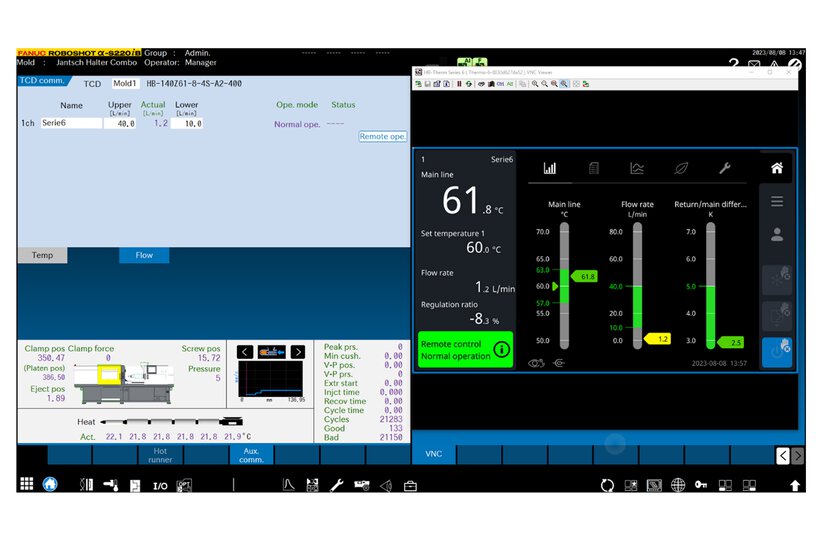

Optimised Resources and Sustainable Moulding Thanks to FANUC

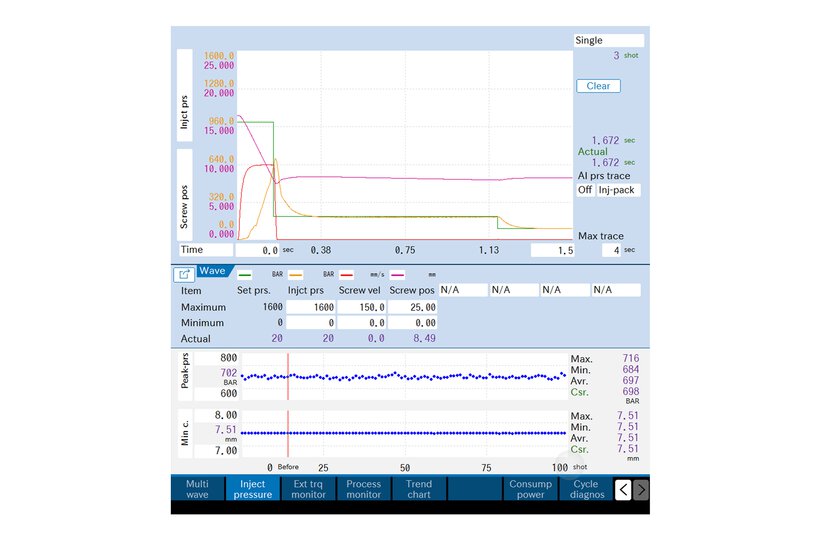

In the food packaging industry, production must be fast, reliable and clean. No wonder Poloplast chose FANUC's ROBOSHOT injection moulding machines. In addition to immediate efficiency improvements and energy savings, the advanced software features on the machines allow the company to further monitor and increase productivity while expanding its range of biodegradable products.

Perfect Fit for Your Application

Injection Moulding

Injection moulding is a highly efficient manufacturing process that enables the production of complex, high-quality plastic components with precision and consistency. Utilising advanced automation and robotics, this technology is essential for industries requiring large-scale production, ensuring cost-effective solutions without compromising on the integrity or performance of the final product.

Tailored Solutions for Your Industry

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

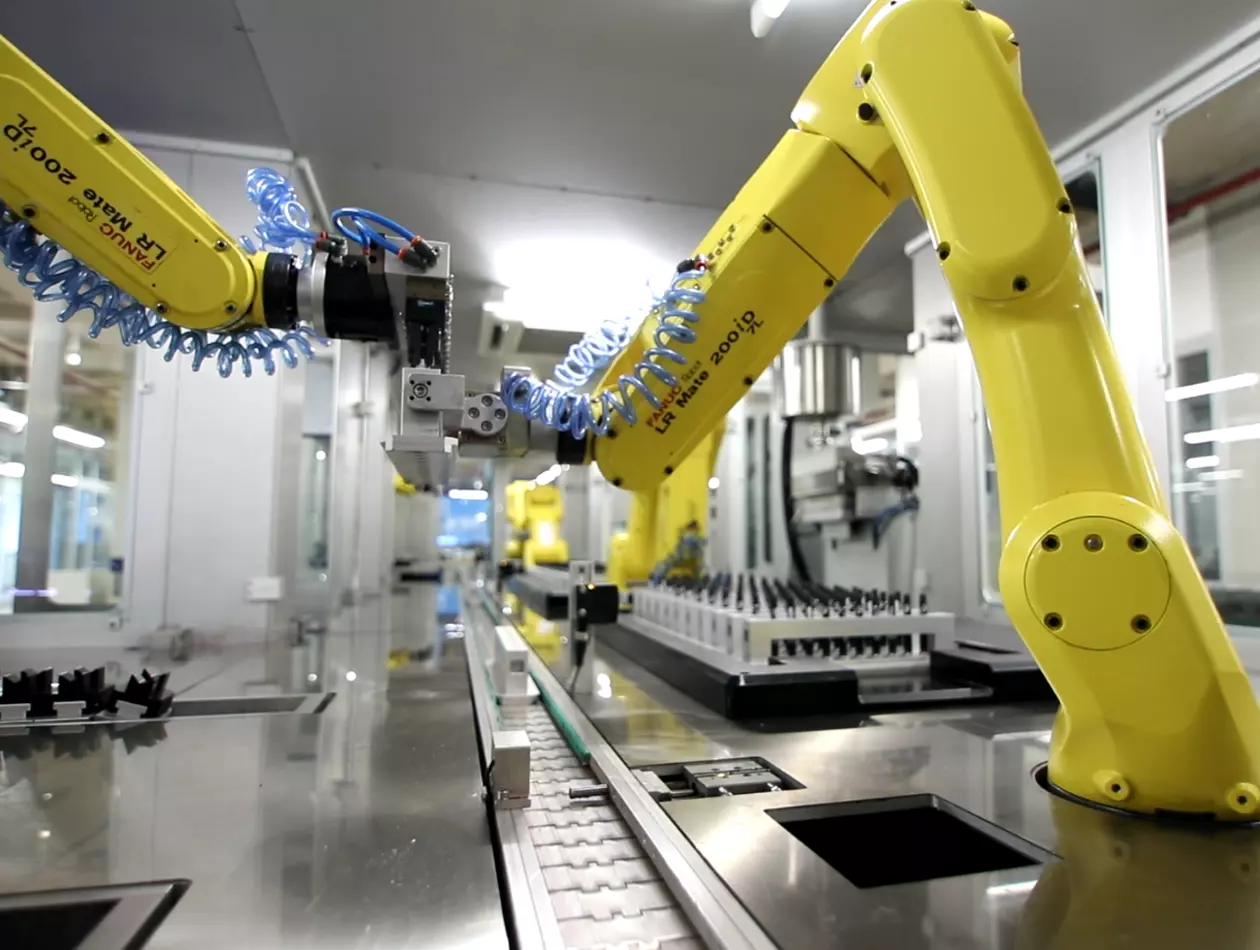

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Advanced Injection Moulding for the Aerospace Industry

Optimise Aerospace Manufacturing with FANUC’s Advanced Injection Moulding Expertise!

Advanced Injection Moulding for the Automotive Industry

Automotive Injection Moulding Excellence with FANUC’s Technology!

Advanced Injection Moulding for the Medical Industry

Consistency and Reliability in Medical Manufacturing Processes!

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.