ROBOSHOT 𝛼-S450𝑖B Small Capacity

Share

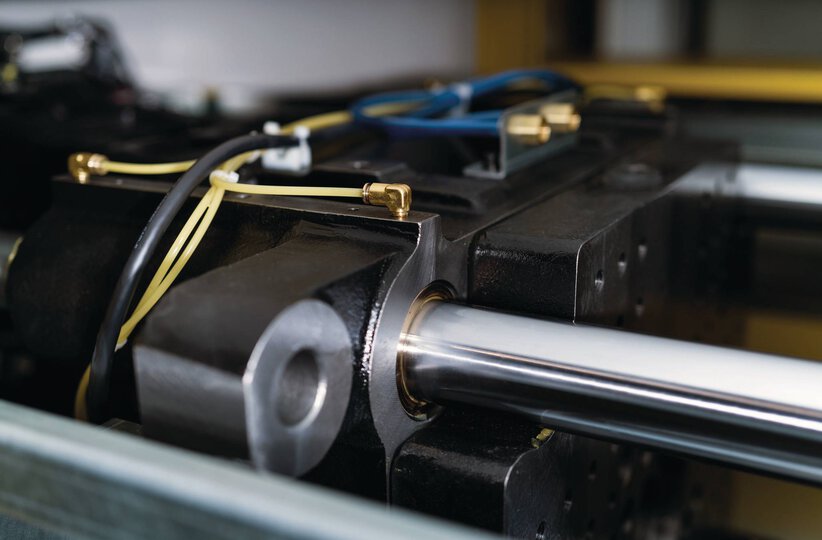

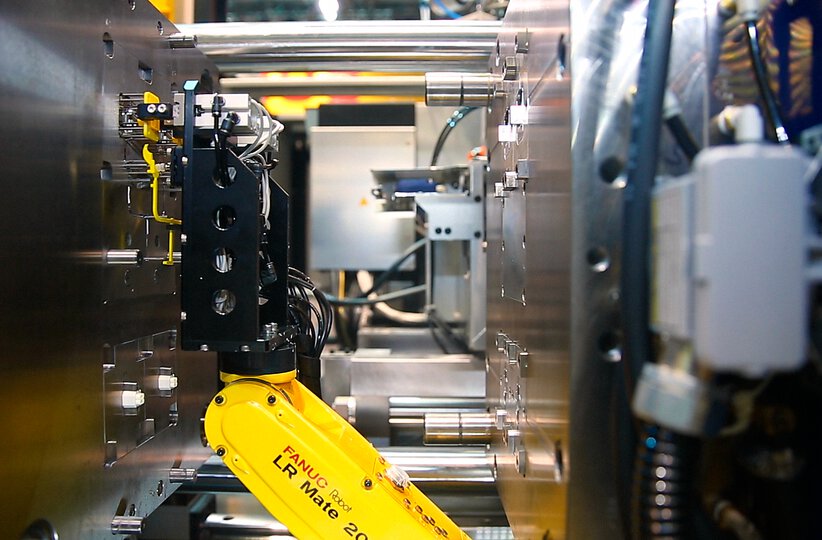

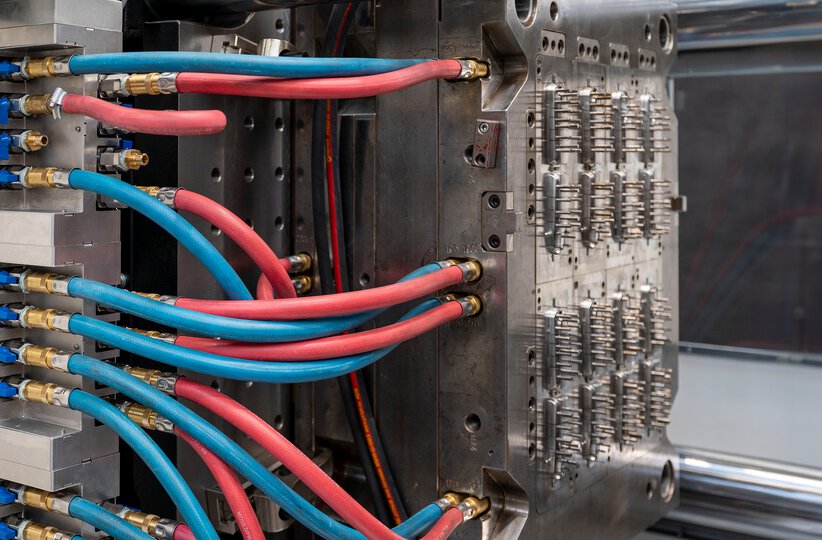

Engineered to exceed the demanding requirements of medical, automotive, and technical moulding industries, this machine sets the standard for excellence in injection molding. Trusted by manufacturers worldwide, it delivers unparalleled reliability and efficiency, ensuring seamless production processes and superior end products.

Tonnage

4500 kN | 450 tonf

Tie bar spacing, H×V

920x920 mm

Screw diameter (mm)

48, 52, 56, 64, 68, 72 mm

Get Inspired

Get Inspiration from Other's Success

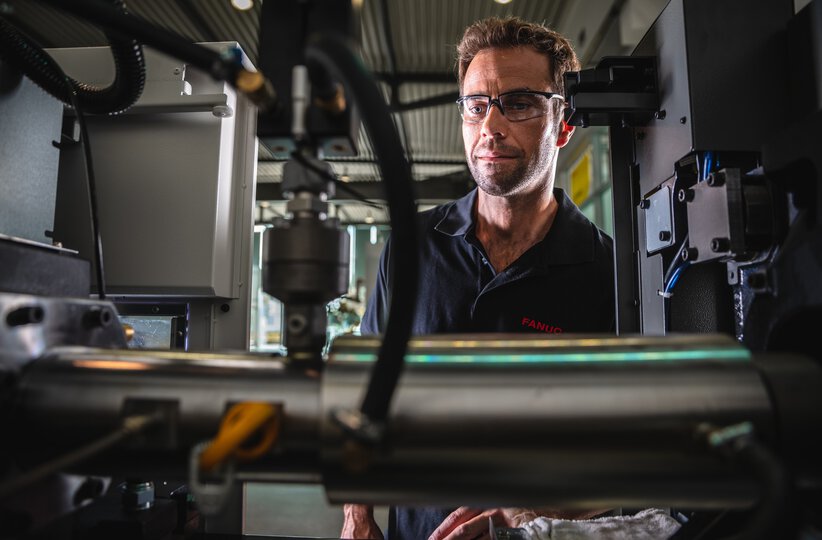

Simon

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

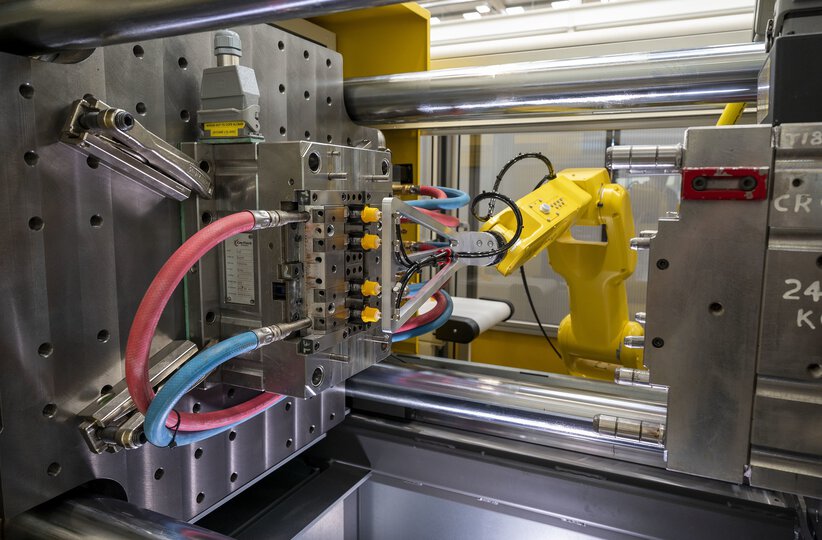

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

Poloplast

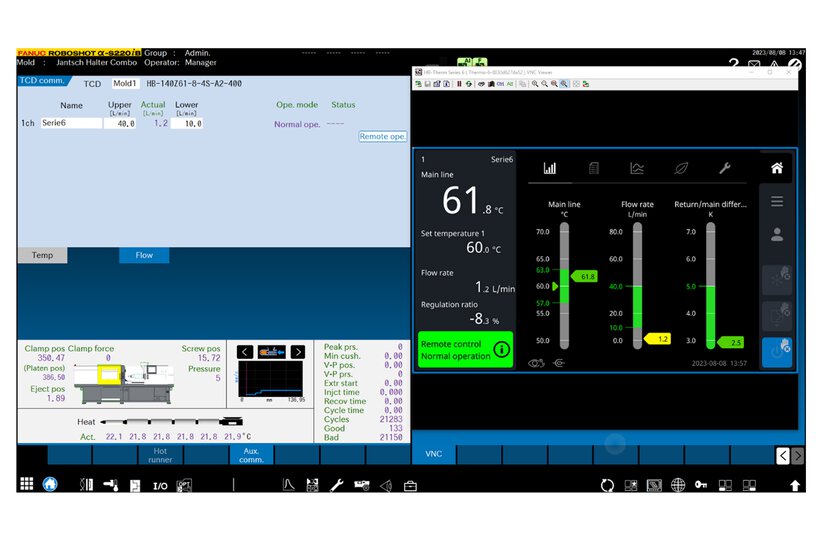

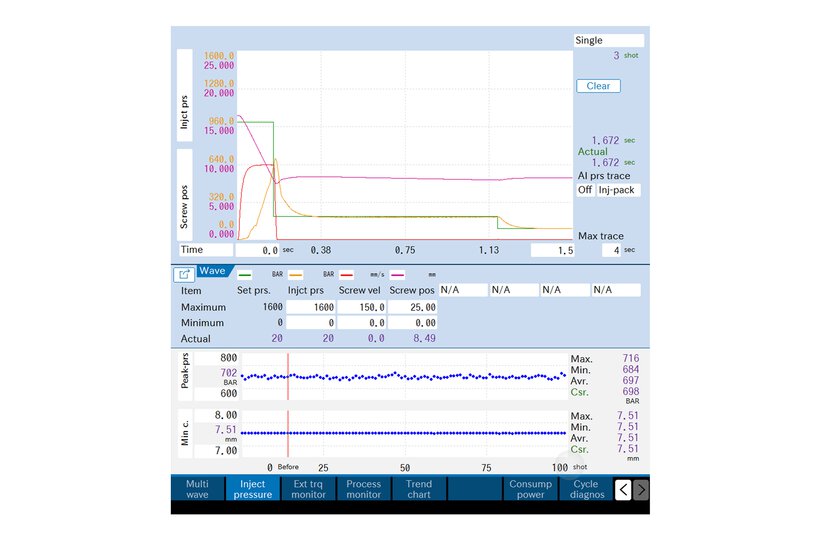

Optimised Resources and Sustainable Moulding Thanks to FANUC

In the food packaging industry, production must be fast, reliable and clean. No wonder Poloplast chose FANUC's ROBOSHOT injection moulding machines. In addition to immediate efficiency improvements and energy savings, the advanced software features on the machines allow the company to further monitor and increase productivity while expanding its range of biodegradable products.

Perfect Fit for Your Application

Injection Moulding

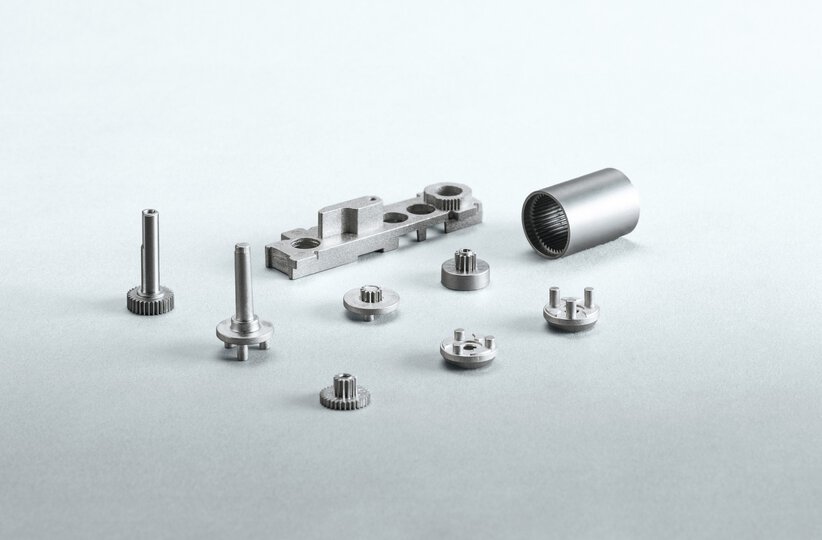

Injection moulding is a highly efficient manufacturing process that enables the production of complex, high-quality plastic components with precision and consistency. Utilising advanced automation and robotics, this technology is essential for industries requiring large-scale production, ensuring cost-effective solutions without compromising on the integrity or performance of the final product.

Tailored Solutions for Your Industry

Food & Beverage

Food & beverage is our bread & butter. Contact us today to put our experience in robots in food & beverage industry to work for you.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Advanced Injection Moulding for the Aerospace Industry

Optimise Aerospace Manufacturing with FANUC’s Advanced Injection Moulding Expertise!

Advanced Injection Moulding for the Automotive Industry

Automotive Injection Moulding Excellence with FANUC’s Technology!

Advanced Injection Moulding for the Medical Industry

Consistency and Reliability in Medical Manufacturing Processes!

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.