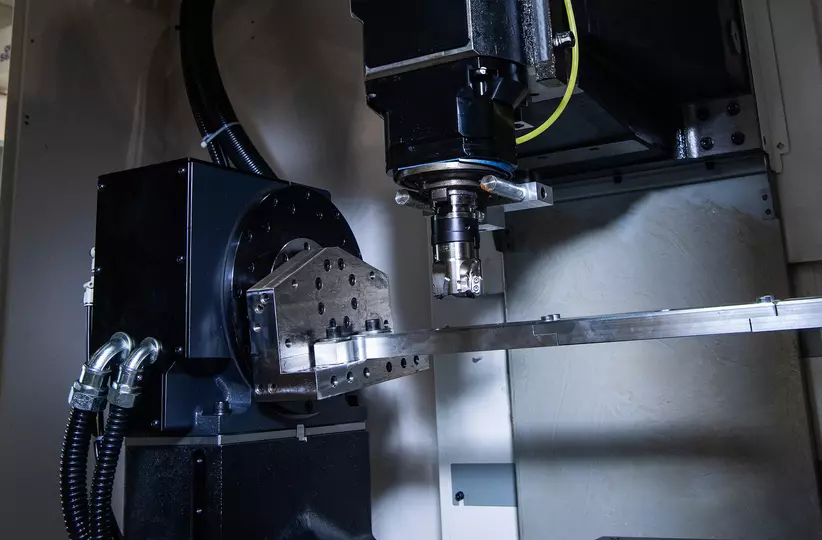

ROBODRILL Compact CNC Machining Centers

Automated Machining for more Versatile Milling, Drilling and Tapping

The new-generation ROBODRILL promises unrivalled quality and precision at great hourly rates. With an unbeatable tool change time of 0.7 seconds and a turret capable of handling tools weighing 4 kg, the new advanced version is the fastest and strongest vertical machining centre on the market. With the shortest cycle times on most machining operations, all ROBODRILL machines are real high-speed all-rounders, offering incredible performance and unbeatable efficiency.

When it comes to new products or changing product numbers, ROBODRILL’s inherent versatility becomes a tangible asset. Instead of relying on a dedicated transfer machine, spreading your machining across several ROBODRILLs allows for higher flexibility across a wide range of applications and industries – saving you money in the process.

Designed to adapt to your every need, FANUC ROBODRILL has a flexibility that covers 3, 4 or even 5 simultaneous axes, thus representing an excellent supplement to your production facilities. Free up larger vertical machining centres for bigger jobs by using our CNCs to absorb extra demand.

Get Inspiration from Others' Success

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

Vedos Achieves Precision with FANUC ROBODRILL

When it comes to finding the right balance between high-precision, efficiency and cost, precision component manufacturer Vedos relies on FANUC’s ROBODRILL milling centers.

Success of FANUC Robot Cell Leads to New Revenue Stream

What do most contract machining companies consider when looking to reach the next level of efficiency, productivity and reliability? The answer, of course, is automation. For this very reason, Germany-based WU Mechanische Werkstätte GmbH built an automation cell -featuring a FANUC industrial robot - for loading and unloading one of its own machine tools. Two years later, a visitor liked the concept so much he asked WU to build him one. This marked the beginning of an additional revenue stream based on the design and build of automation cells featuring high-performance industrial robots from FANUC.

FANUC robots enable 24/7 CNC machining at RADMOT

Automated CNC machining cells comprising various machine tools and robots require astute design and integration. So why not simplify the process by turning to the world’s most prominent manufacturer of both CNC machine tools and robots: FANUC. That was precisely the strategy of RADMOT, a major Poland-based provider of machining services when it wanted to implement a new CNC milling cell involving three machining centres and two robots that could run unmanned 24 hours a day, 7 days a week – without any collisions between robots.

Perfect Fit for Your Application

CNC Milling

5 Axis Machining

Tailored Solutions for Your Industry

Electronics

Complex Machining for the Automotive Industry