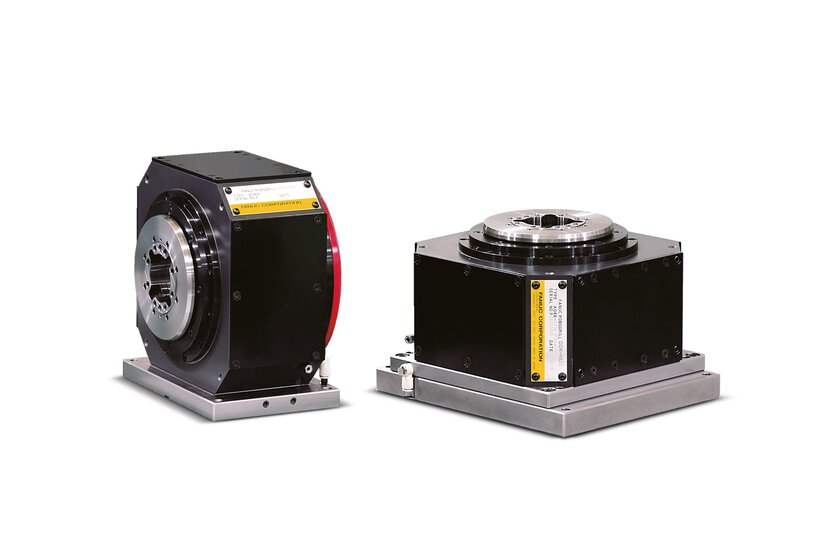

ROBODRILL 𝛼-D21M𝑖B5 Plus

Get Inspired

Get Inspiration from Other's Success

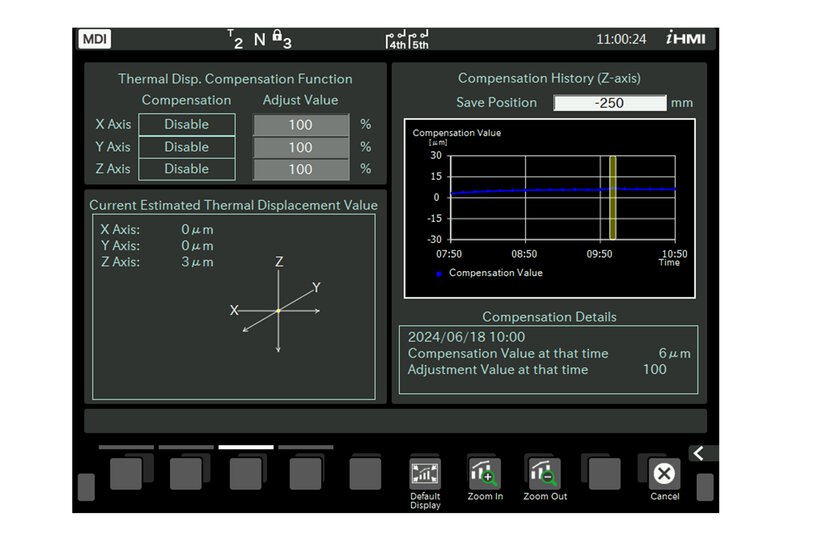

Higher machining throughput and product quality with FANUC

Investing in a new machine tool typically comes with a checklist that includes priorities such as precision, speed, efficiency and reliability. While many machines claims to meet these objectives, only actual results in real-world applications can qualify such assertions. And where better to test the merits of FANUC machines than a high-volume machine shop serving sectors that include automotive, white goods and electronics. The results speak for themselves.

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

FANUC Provides Vision of the Future at ZAP

While machining can benefit greatly from the adoption of a machine-tending robot, the addition of 3D cameras introduces an extra level of intelligence that leads to autonomous production and particular benefits for manufacturers.

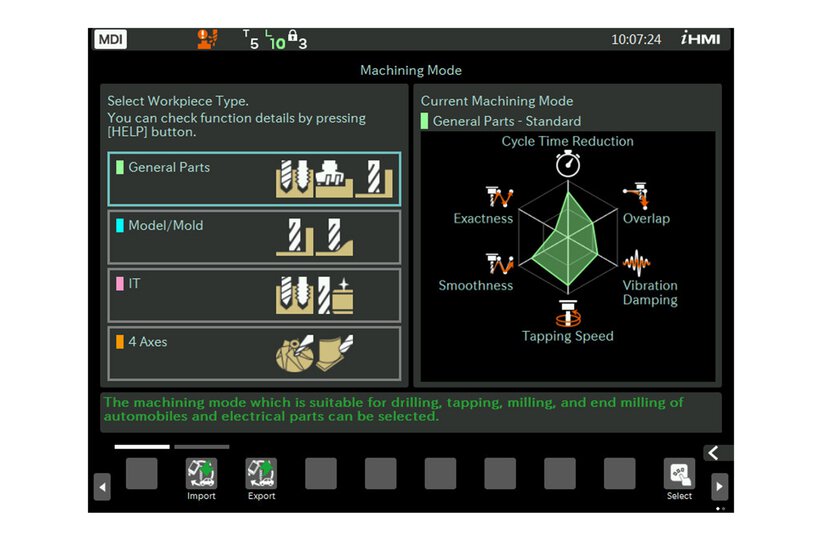

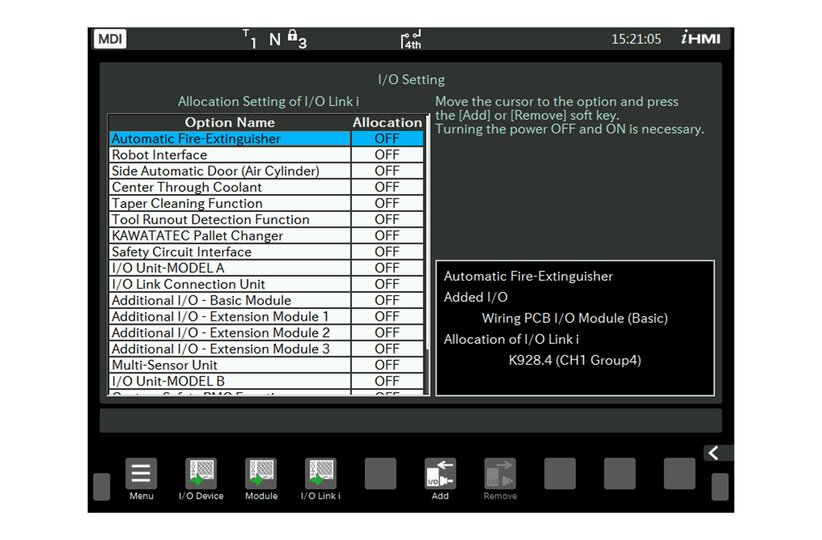

Perfect Fit for Your Application

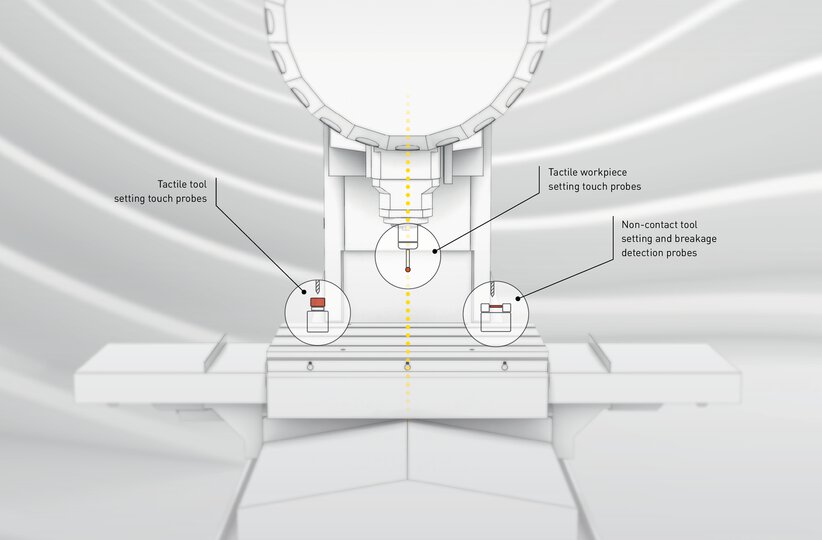

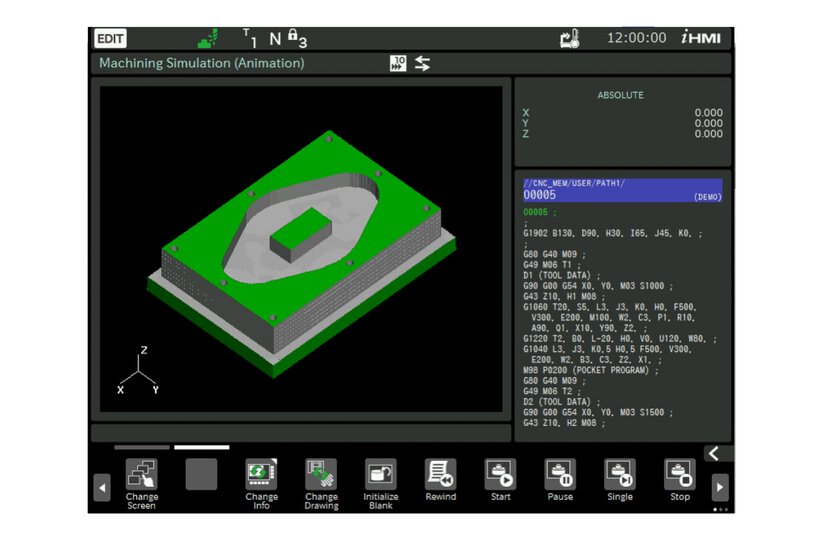

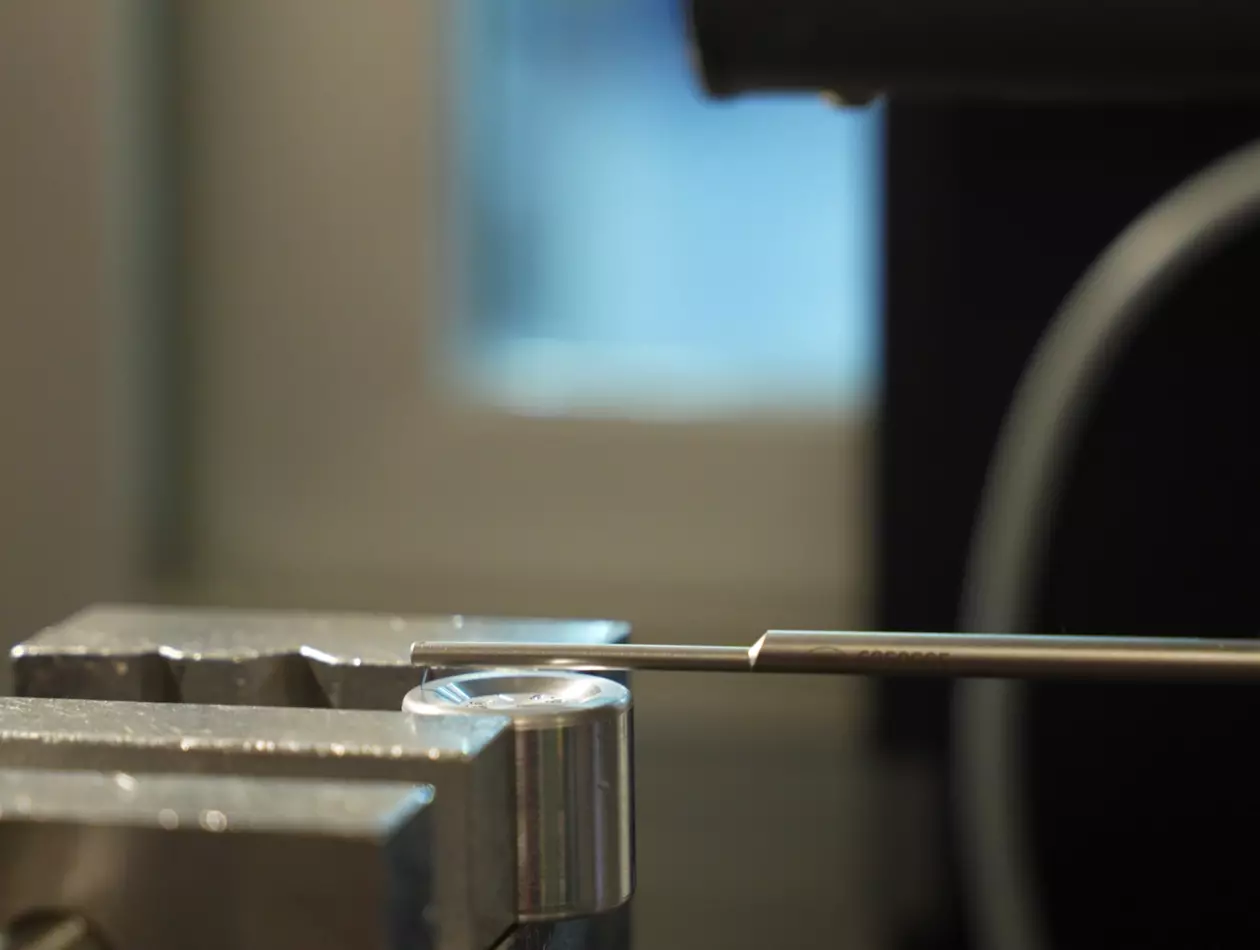

CNC Milling

5 Axis Machining

Tailored Solutions for Your Industry

Electronics

Complex Machining for the Medical industry

Complex Machining for the Automotive Industry