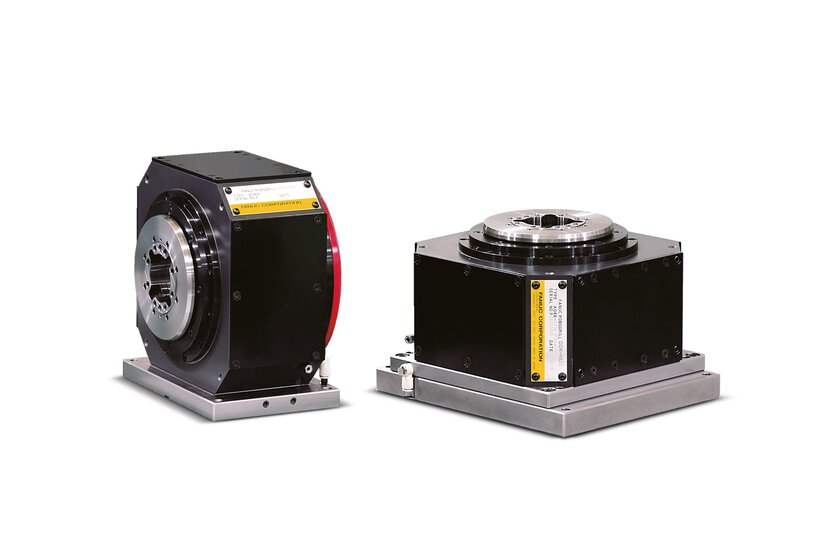

ROBODRILL 𝛼-D21S𝑖B5 ADV Plus

Share

When it comes to executing high-precision operations within a limited workspace, look no further – this is the perfect solution. It emerges as an exceptional machining solution, catering to industries such as watchmaking, jewelry, life sciences, electronics, and more.

Table size

630x330 mm

Travel X/Y/Z

300/300(+100)/400

Max. table load

200 kg

Get Inspired

Get Inspiration from Other's Success

Euroedil

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

ZAP-Mechanika

FANUC Provides Vision of the Future at ZAP

While machining can benefit greatly from the adoption of a machine-tending robot, the addition of 3D cameras introduces an extra level of intelligence that leads to autonomous production and particular benefits for manufacturers.

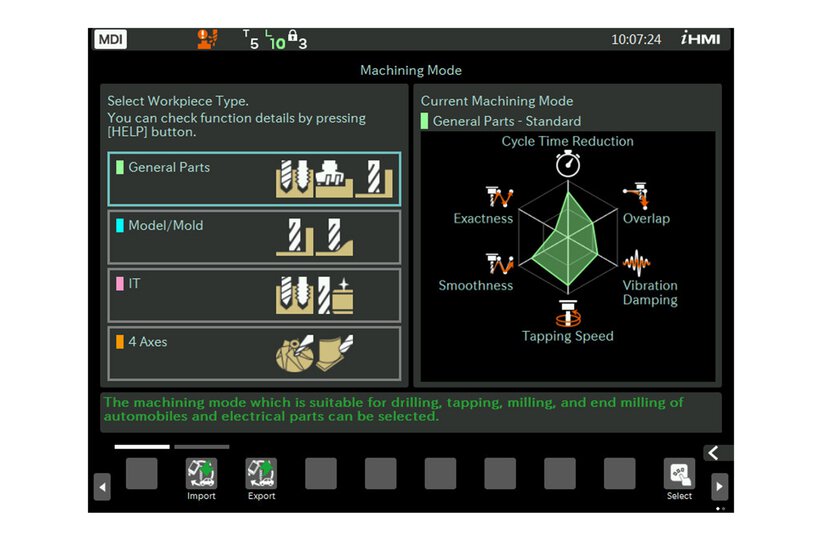

Perfect Fit for Your Application

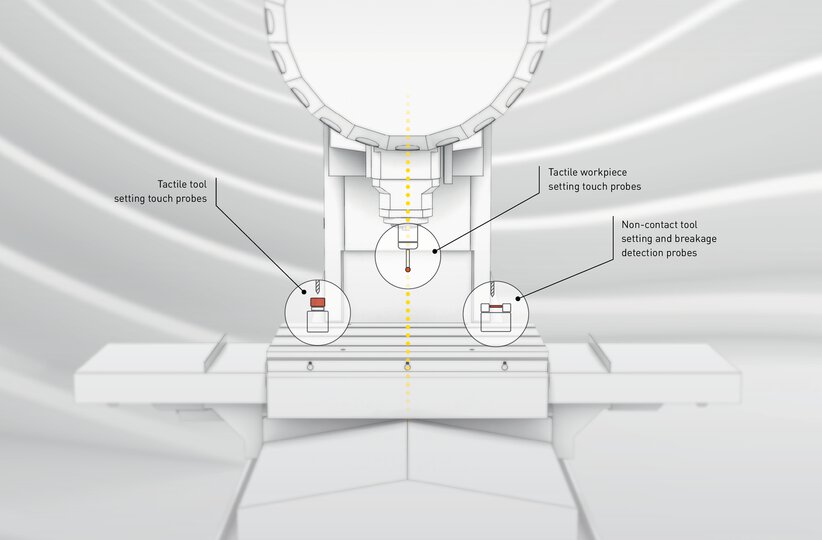

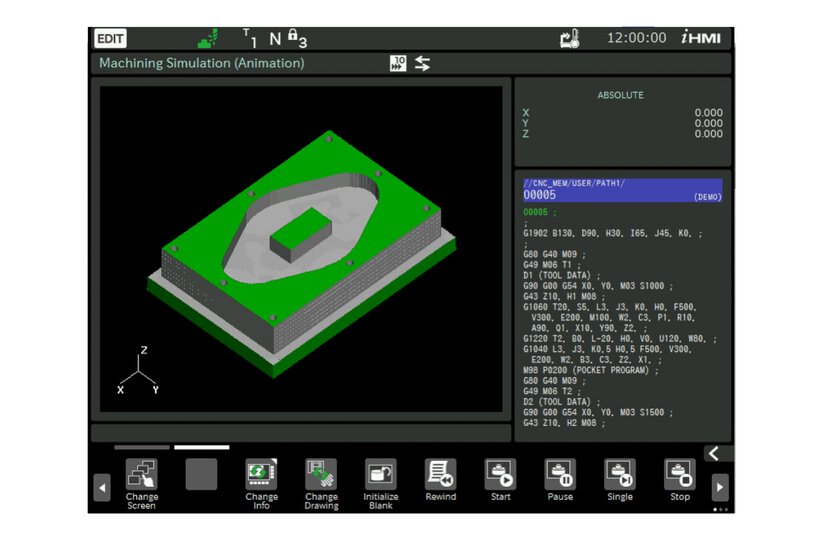

CNC Milling

CNC milling is a machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece to create a desired shape. It is widely used for producing precision parts with complex geometries. The process involves securing the workpiece on a movable table and using various tools to cut, drill, and shape the material based on programmed instructions.

5 Axis Machining

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency. By moving the cutting tool and workpiece along these five different axes, the 5-axis CNC can produce highly intricate shapes and detailed features.

Tailored Solutions for Your Industry

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Complex Machining for the Medical industry

Medical Manufacturing Excellence with FANUC's Technology!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!