Akim Metal - SMB

CNC Lathe Builder Takes Control of Production with FANUC

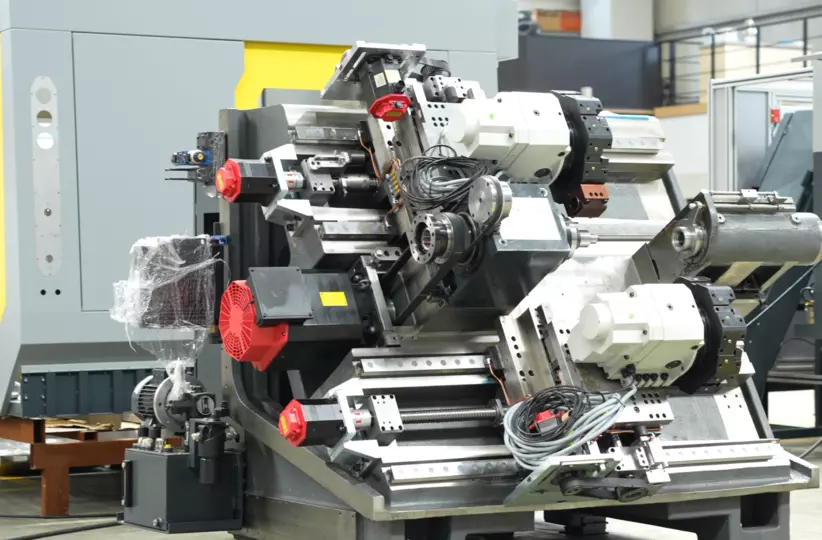

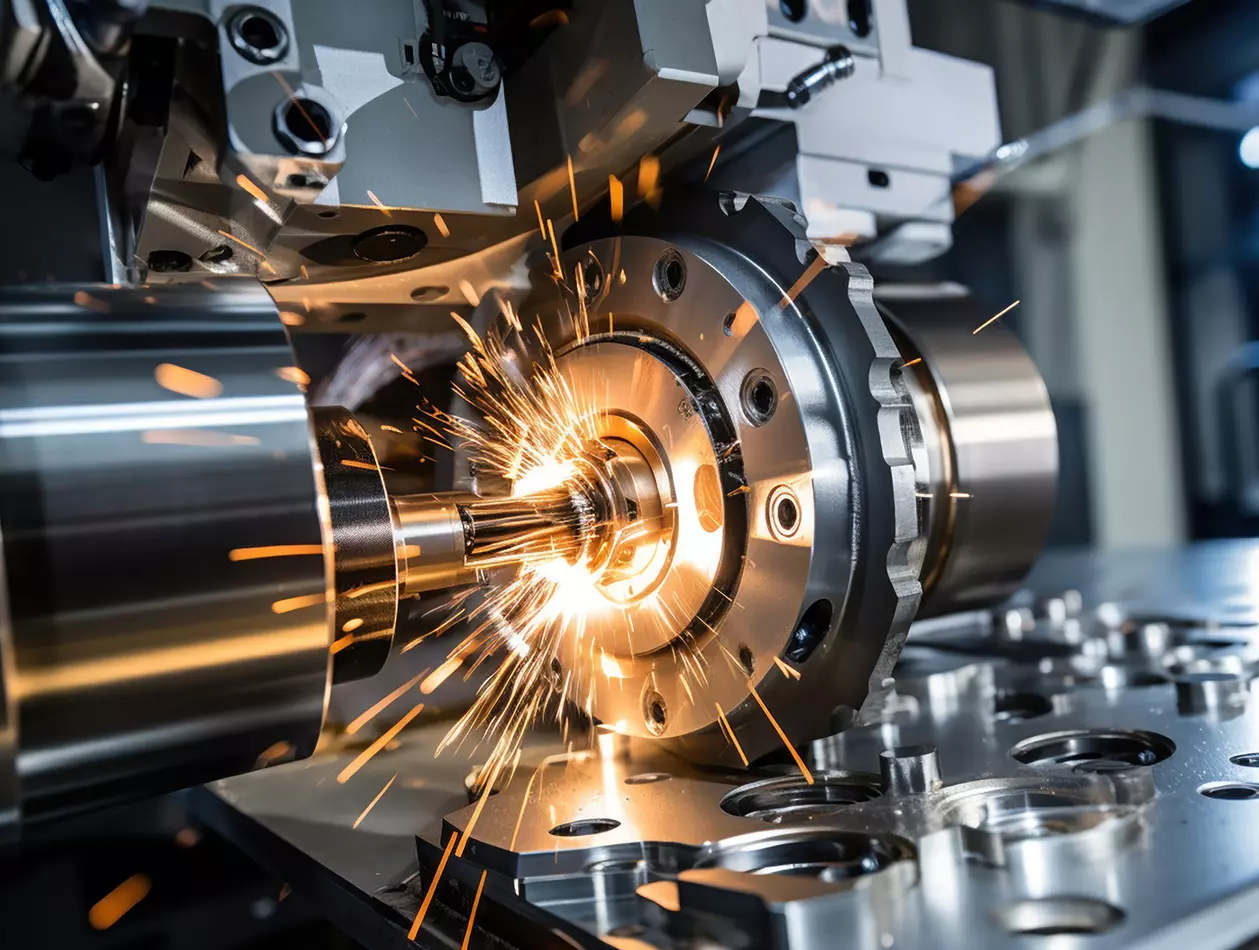

In a world of increasingly complex engineering components, machine tools require ever-more capabilities and functions. The humble lathe, a mainstay of the machining industry, is a case in point. The SMB brand of Türkiye-based Akim Metal today builds lathes with servo-controlled twin turrets, programmable steady rests, live tools, programmable tailstock and integrated automation. To provide optimal process control in the hunt for ever higher component quality, repeatability and productivity, the company takes advantage of FANUC CNC systems.

Megosztás

A FANUC CNC vezérlések széleskörű esztergálási funkciókat tesznek lehetővé az SMB esztergákon.

Az excentrikus tengelyek nem jelentenek problémát a FANUC 0𝑖-TF Plus CNC számára

A szimultán kétcsatornás vezérlés könnyedén kezeli külön a két revolverfejet

Átfogó támogatás a FANUC helyi szerviz- és mérnöki csapatától

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

CNC esztergálás

A CNC gépek olyan megmunkálási folyamatok, amelynek során egy szerszámgép anyagot távolít el egy forgó munkadarabról, hogy pontos hengeres alakzatokat hozzon létre. Ideális összetett geometriájú és szűk tűréshatárokkal rendelkező alkatrészek gyártására. Az esztergaközpont vagy esztergapad teljesítményének maximalizálásához elengedhetetlen egy jó CNC, amely képes kezelni és optimalizálni az esztergálási folyamatok egész sorát. A termelékenység maximalizálása mellett egy jó CNC rugalmasságot is biztosít Önnek a kis tételek átfutási idejének csökkentéséhez.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.