LR-10𝑖A/10

Get Inspired

Get Inspiration from Other's Success

FANUC Robots Automate Coin Production at Swissmint

Automating the full minting process from individual coins to finished palletised boxes is no mean feat. However, that was the task facing Swissmint, the Federal Mint of Switzerland. To make this complex concept a reality, Swissmint deploys high-performance FANUC robots in tasks that include pick and place, assembly of boxes and palletisation.

A Safe Space for Implant Machining

Machine tending (loading and unloading) is one of the most popular applications for an industrial robot thanks to the elimination of labour costs and higher production throughput. However, in a busy industrial plant, how is it possible to ensure the safety of employees in close proximity to such a fast and powerful installation? The use of FANUC Dual Check Safety technology at world-leading medical technology company Smith+Nephew, demonstrates the optimal solution.

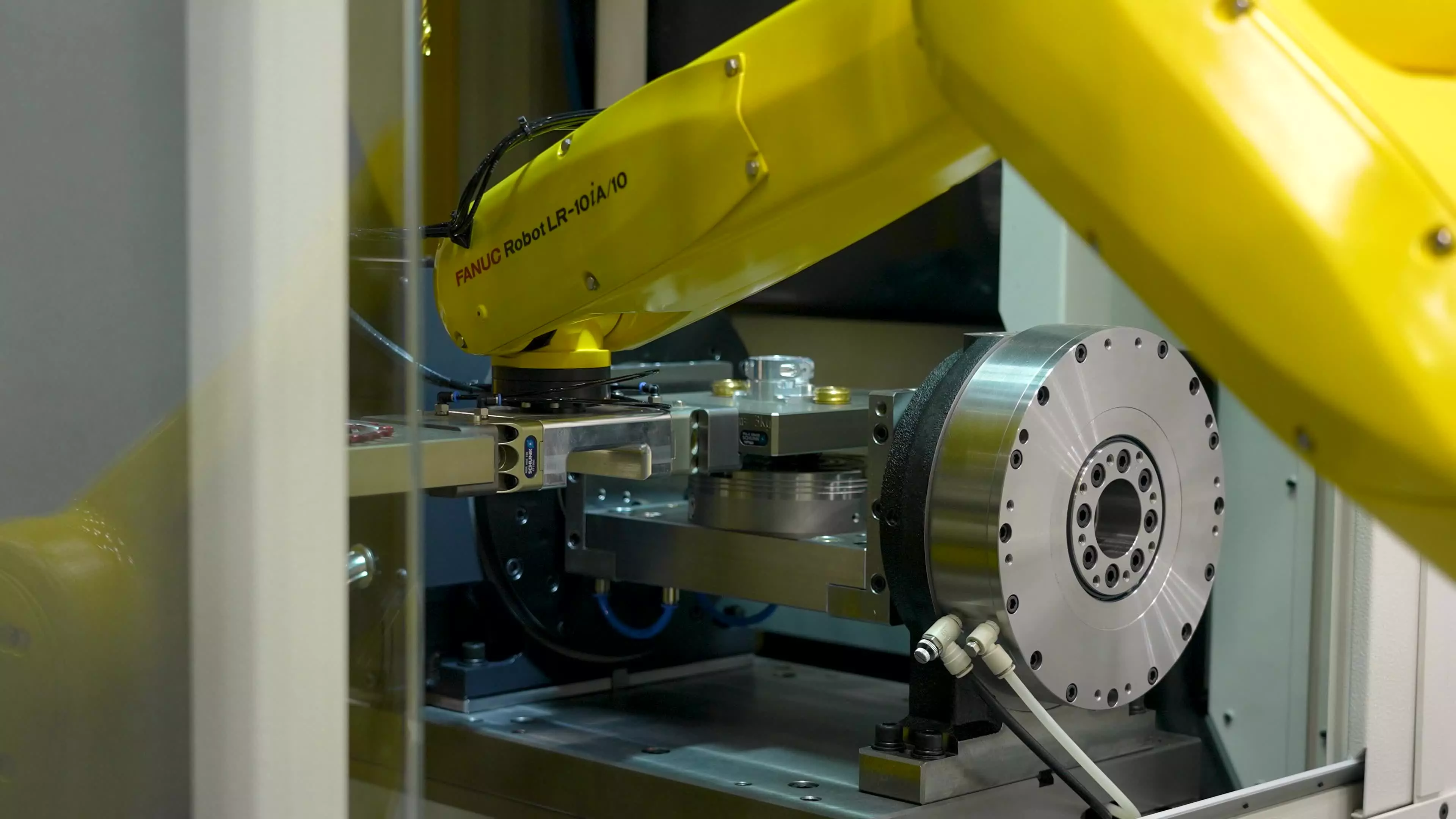

Success of FANUC Robot Cell Leads to New Revenue Stream

What do most contract machining companies consider when looking to reach the next level of efficiency, productivity and reliability? The answer, of course, is automation. For this very reason, Germany-based WU Mechanische Werkstätte GmbH built an automation cell -featuring a FANUC industrial robot - for loading and unloading one of its own machine tools. Two years later, a visitor liked the concept so much he asked WU to build him one. This marked the beginning of an additional revenue stream based on the design and build of automation cells featuring high-performance industrial robots from FANUC.

Perfect Fit for Your Application

Machine Tending

Material Handling

Assembling

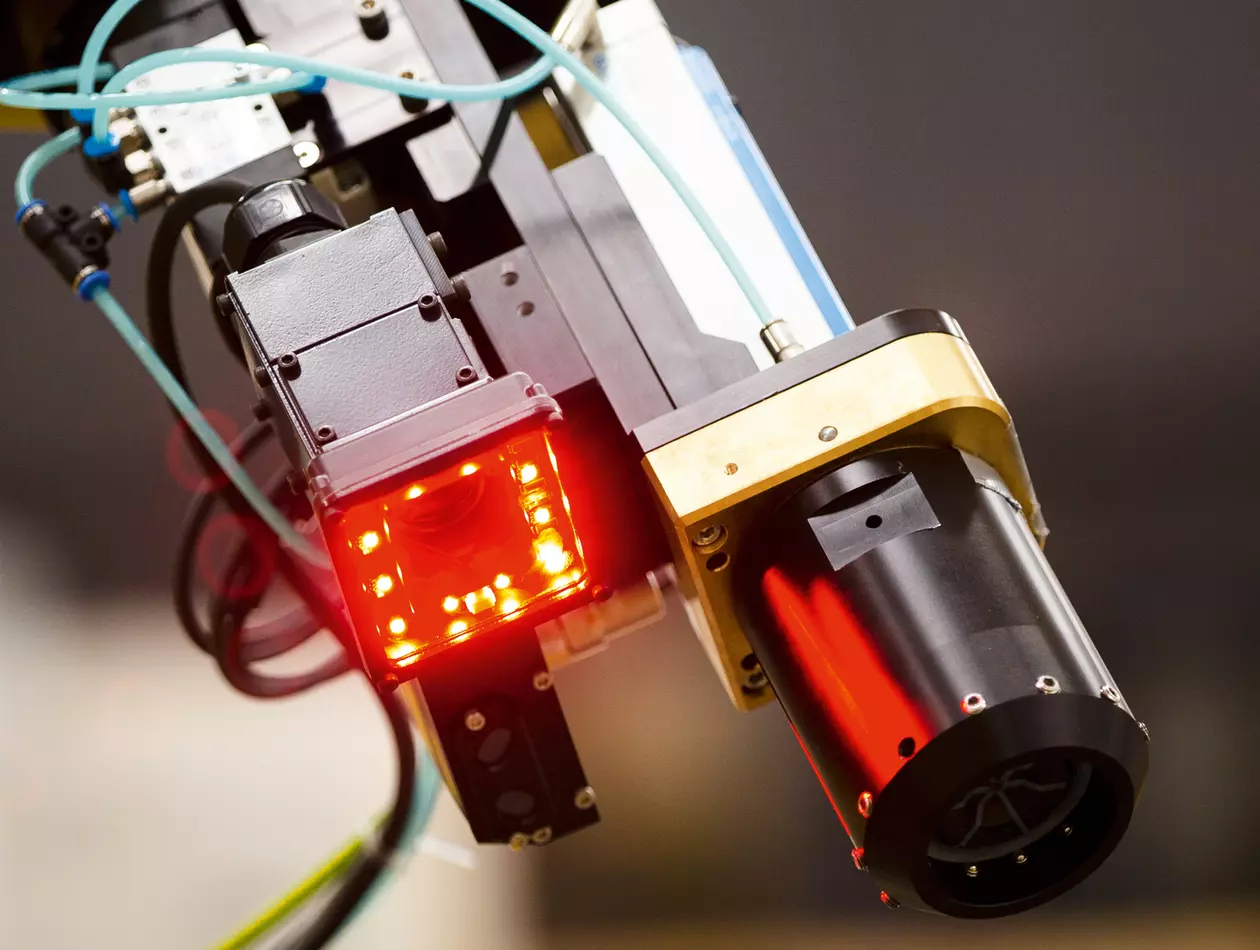

Vision Inspection

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

Robotics & Automation for the Automotive Industry

Electric Vehicles

Electronics

Food & Beverage

Robotics & Automation for the Medical Industry