Plastics

Smart Automation of Processing, Handling and Picking Tasks for the Complete Plastics Value Chain

FANUC offers a wide range of versatile automation solutions to help you make your plastics business more efficient. Whatever the process – be it injection moulding, machining, machine tending, parts handling or palletising – FANUC can provide you with everything from a standalone machine, such as the ROBOSHOT injection moulding machine or plastics machining centre, to a dedicated production cell complete with robots and advanced Power Motion control. No matter what you choose, not matter how big or small your solution, the centrepiece of every FANUC installation is the world’s most reliable CNC. Providing a common platform for everything that FANUC makes, when combined with advanced FANUC machining and robotics solutions it is the key to increasing your productivity, improving your efficiency and driving down your cycle times.

- Application

- Related products

- Benefits

- Case Studies

Robotics & Automation for the Plastic Industry

Material Removal

Painting & Coating

End-of-the-Line Automation

Injection Moulding

Wire EDM Cutting

Picking & Placing

Assembly

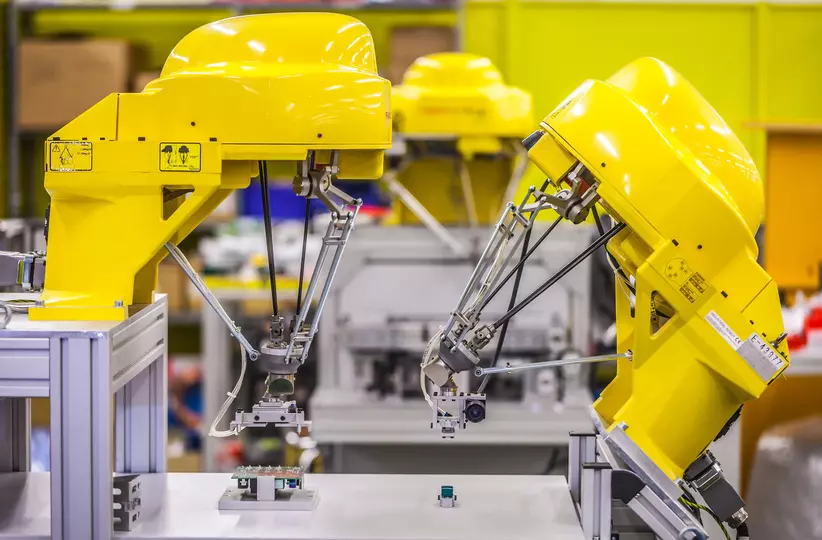

Picking & Placing

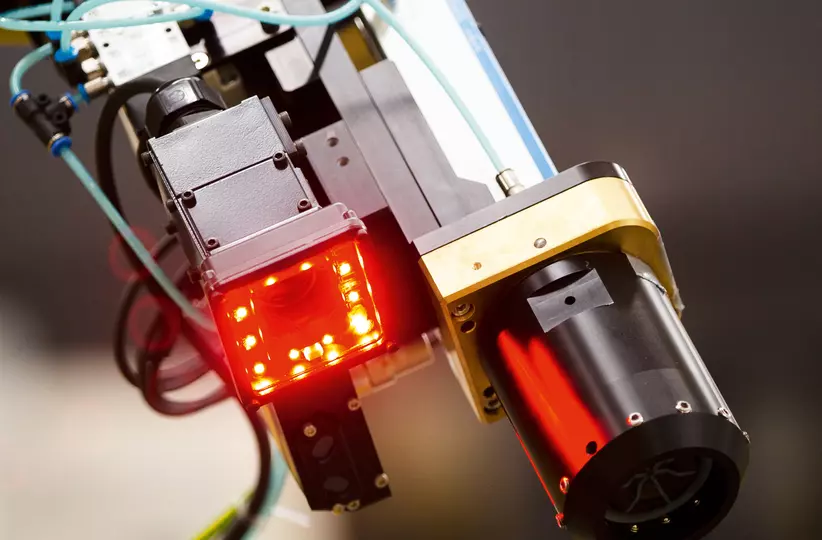

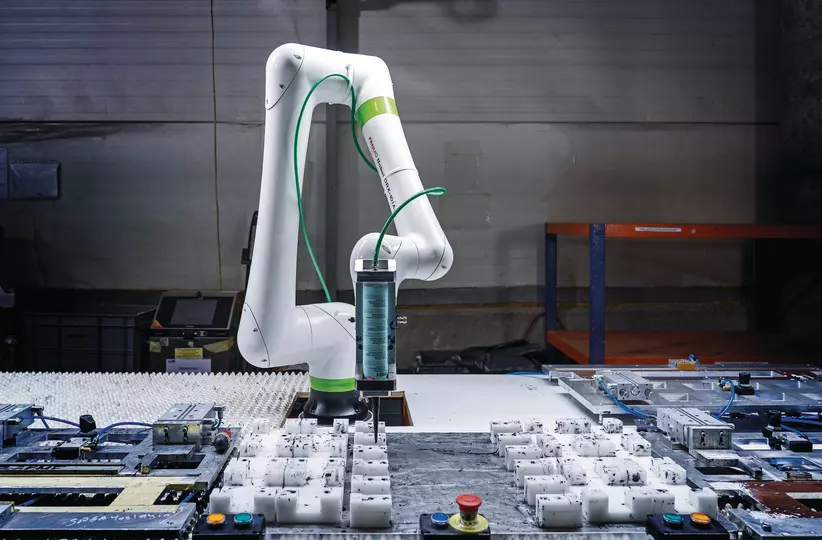

Automating pick, place, and sorting tasks optimises production processes and enhances flexibility, helping plastic manufacturers stay competitive. FANUC smart visual recognition and sensor systems for line tracking and picking tasks significantly improve handling in plastics manufacturing.

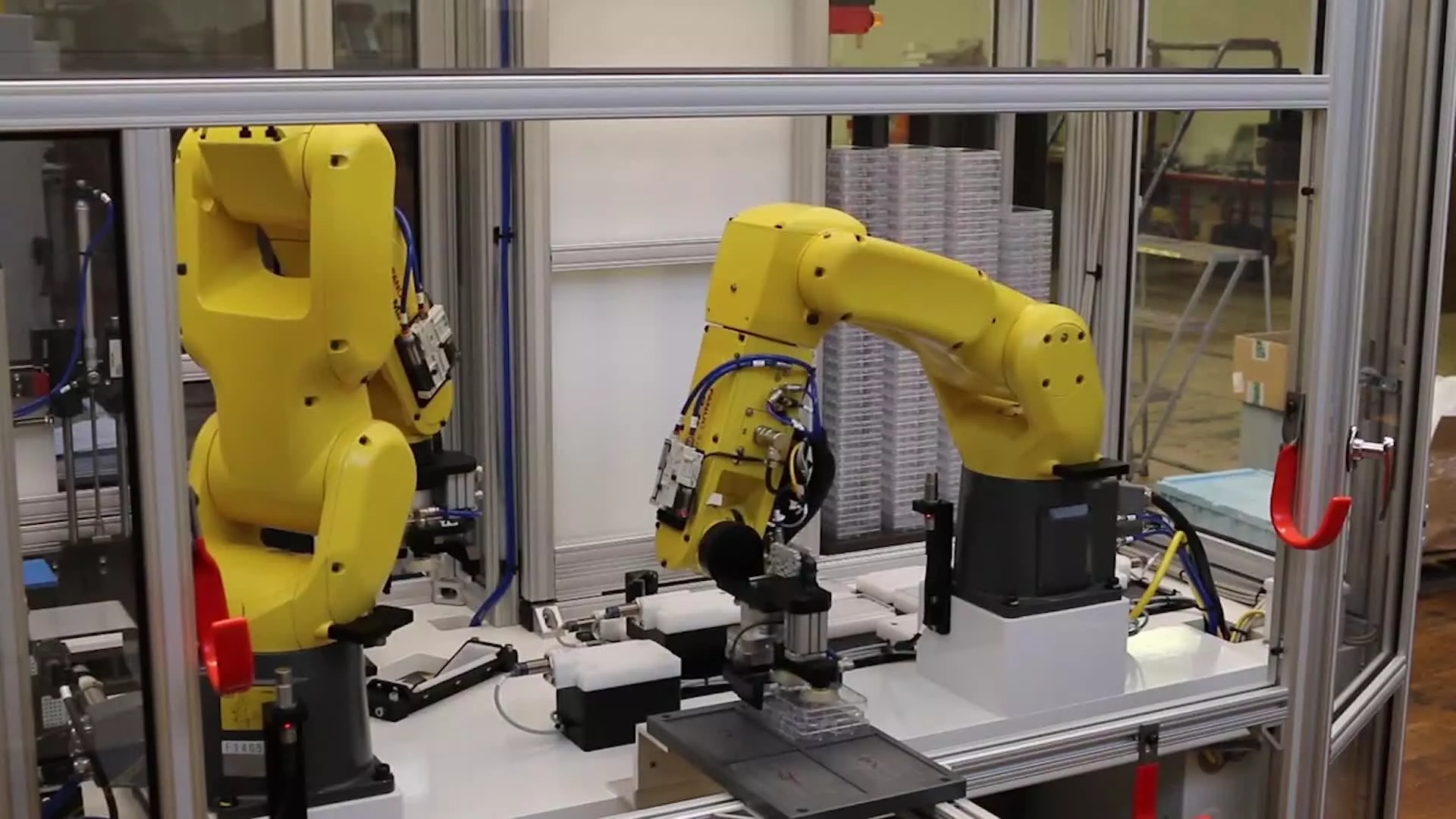

Assembly

FANUC wide offer of Robots and Cobots provide precise and reliable automation that enhances assembly speed, accuracy, and overall production efficiency.

Material Removal

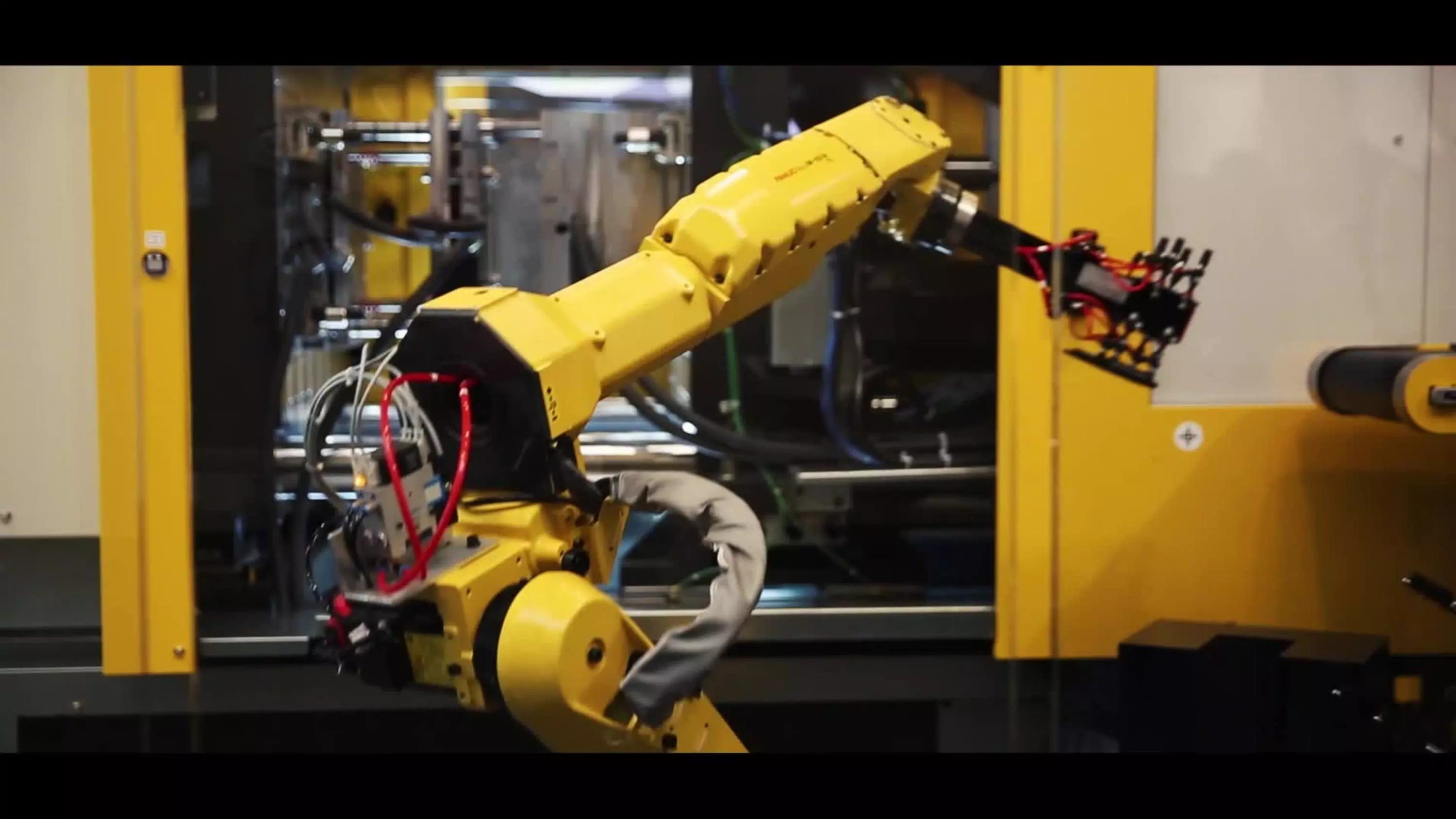

FANUC robots, equipped with advanced Force Sensors, excel in plastic material removal applications. The Force Sensors ensure accurate deburring and polishing delivering high-quality finishes and consistent results, minimising manual intervention and reducing wastes.

Painting & Coating

FANUC paint robots are suitable for a wide variety of painting, powder/liquid coating and fiberglass reinforced plastic (FRP Chop/Gel) applications. We have the industry’s widest range of paint robots to boost operations and keep workers safe by automating tasks that could potentially expose them to harmful chemicals.

End-of-Line Automation

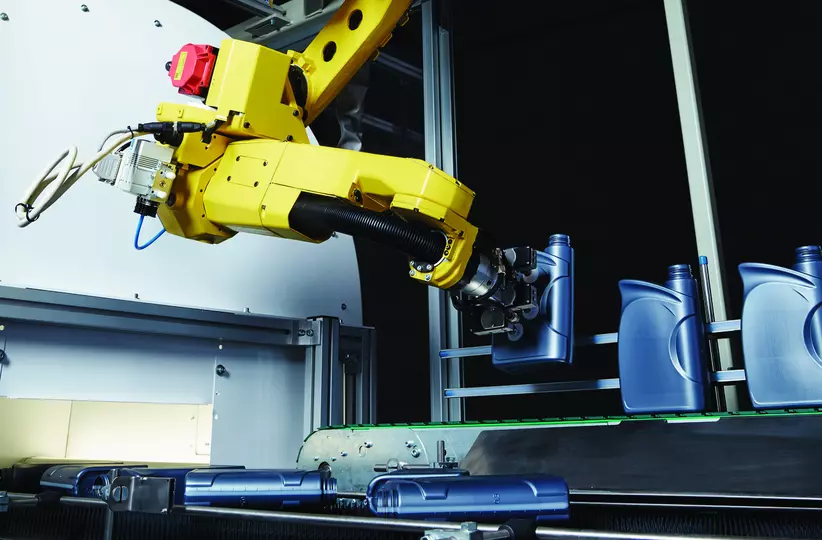

Automating end-of-line processes, such as labelling, packing and palletising, with high-speed and adaptable FANUC robots, improves overall efficiency and consistency in the final stages of plastic manufacturing.

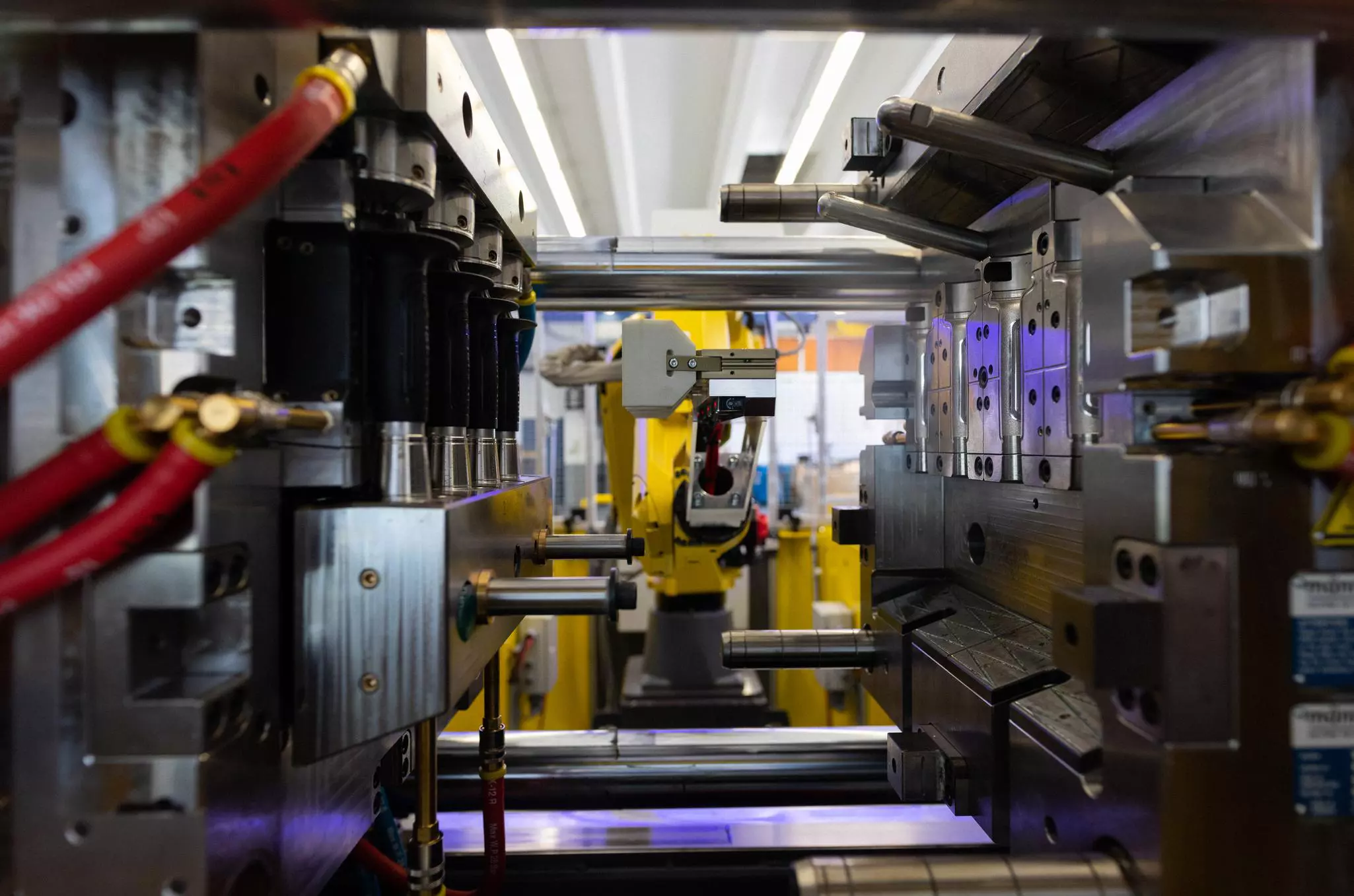

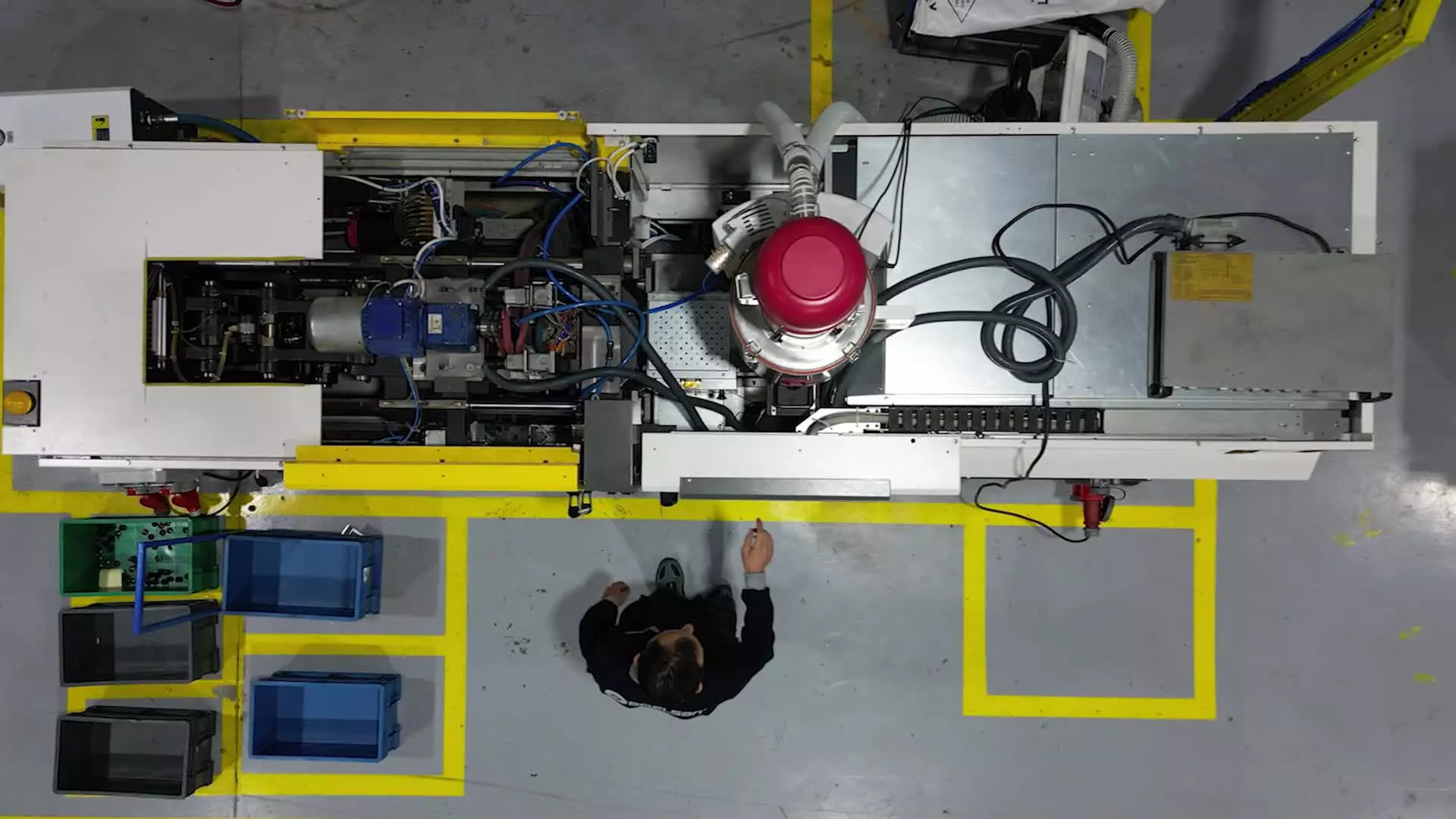

Injection Moulding

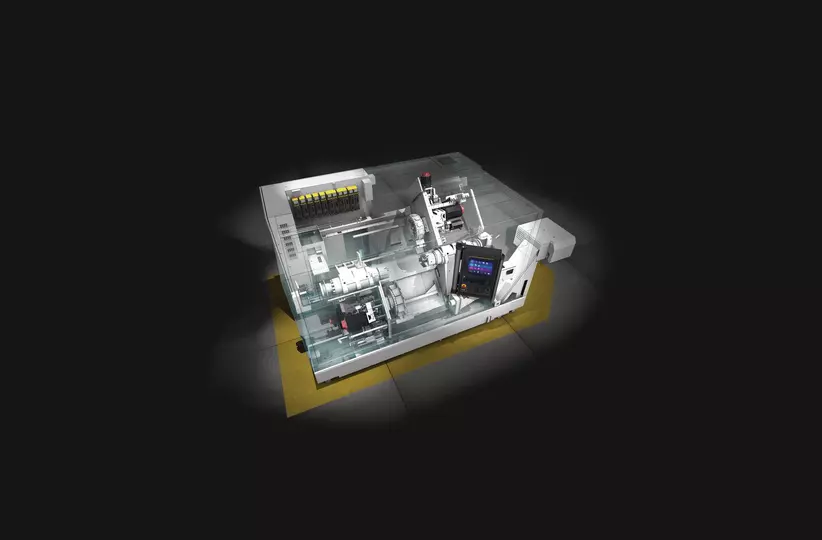

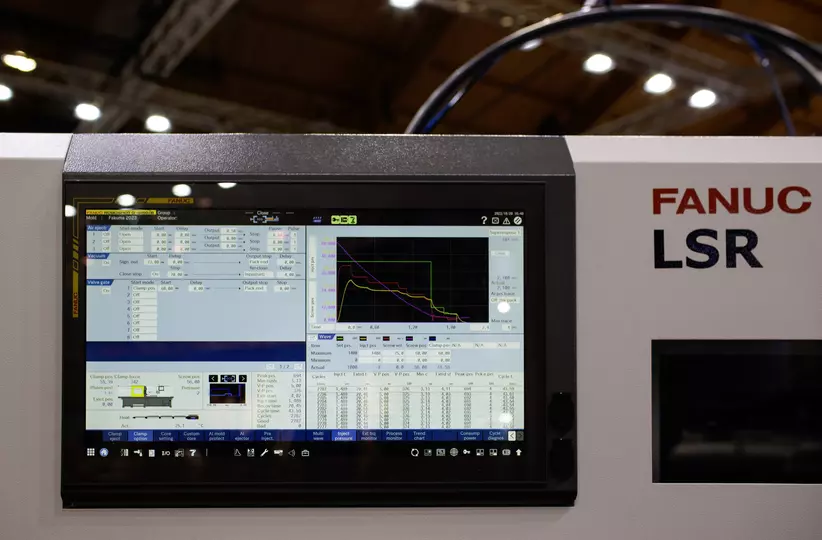

FANUC employs this same state-of-the art CNC technology in ROBOSHOT machines to provide an unrivalled electric injection moulding solution. The results are huge versatility, utmost precision of movement and extremely short cycle times to produce larger quantities of consistently high-quality parts.

Wire EDM Cutting

With its extensive range of options ensuring pristine surfaces and incredible accuracy of parts, ROBOCUT stands out as the perfect all-rounder for the plastics industry. FANUC’s wire EDM demonstrates extremely high accuracy on tooling, such as moulds. The machine's incredible levels of repeatability further guarantee that the same high standards are consistently obtained.

Our Products for the Plastics Industry

Highlights

Collaborative Robots

Multi-Component Injection Moulding

CNC precision for higher productivity

Benefits for your Industry

Increased Productivity

Precision Handling

Improved Consistency

Seamless Integration

Advanced Injection Moulding

Enhanced Safety

Cost Savings

Energy efficiency

Lifecycle support

Optimised Resources and Sustainable Moulding Thanks to FANUC

In the food packaging industry, production must be fast, reliable and clean. No wonder Poloplast chose FANUC's ROBOSHOT injection moulding machines. In addition to immediate efficiency improvements and energy savings, the advanced software features on the machines allow the company to further monitor and increase productivity while expanding its range of biodegradable products.

FANUC ROBOSHOT Machines Keep Things Simple for SIMON

High-volume plastics parts; thin walls; zero defects; short automotive lead times; demanding energy efficiency requirements. A growing number of manufacturers are combatting these common challenges by investing in ROBOSHOT high-performance, all-electric injection moulding machines from FANUC. Among their number is SIMON Plastics.

Injection Moulding Shop Shapes its Future with FANUC

There are numerous plastic injection moulding machines available on the market, but most modern manufacturers seek a core set of key attributes based on flexibility, energy efficiency and performance. As a result, the highly capable FANUC ROBOSHOT, with its potential for rapid tool changes and all-electric low energy consumption, is a proven choice for any manufacturer of plastic products looking to become more competitive and gain market share. Among those able to provide testimony is Hungary-based Viskiplast.

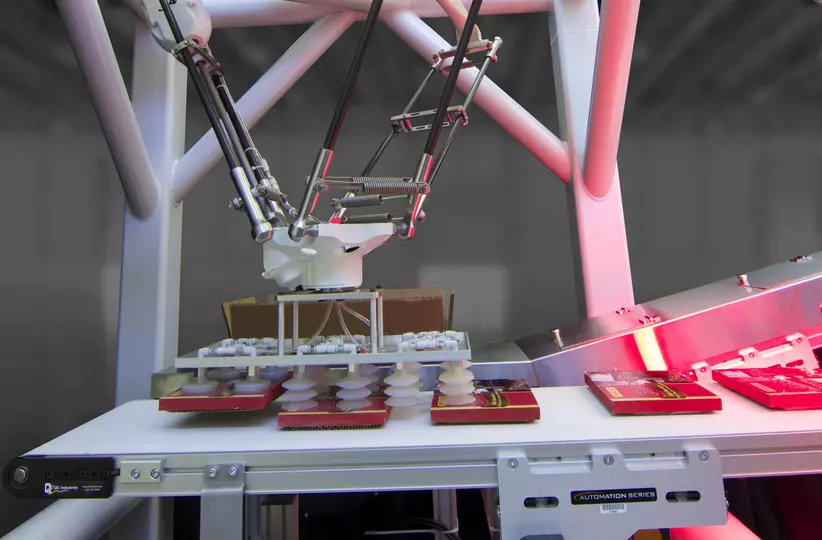

Placing Plastic Injection-Moulding into Packing Trays

Because manufacturers everywhere face shortages of skilled labor, and as a company dedicated to excellence, Kunstoff-Packungen continuously seeks ways to improve its level of automation.

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.