CR serie

Verbeter de efficiëntie en veiligheid van uw productielijn met de CR Collaboratieve Robot serie van FANUC. Kies voor het hoogste draagvermogen op de markt, ondersteund door FANUC's befaamde betrouwbaarheid en gebruiksgemak.

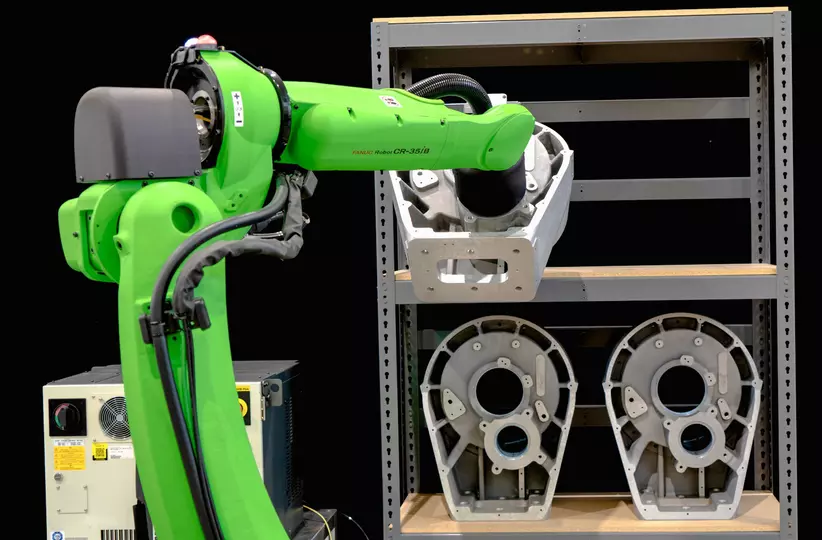

Maak kennis met de sterkste cobot

Met een indrukwekkend draagvermogen tot 50 kg kan de CR-35𝑖B samenwerken met operators in uiteenlopende toepassingen die normaal gesproken tilhulpmiddelen of speciaal aangepaste apparatuur vereisen. Naast het feit dat het de sterkste cobot in de industrie is, beschikt de CR-35𝑖B over een groot werkbereik en een compacte installatievoetafdruk, waardoor hij ideaal is voor krappe ruimtes.

De gestroomlijnde en lichtere mechanische eenheid is uitgerust met FANUC’s nieuwste sensortechnologie voor optimale veiligheid.

Laat u inspireren!

Haal inspiratie uit het succes van anderen

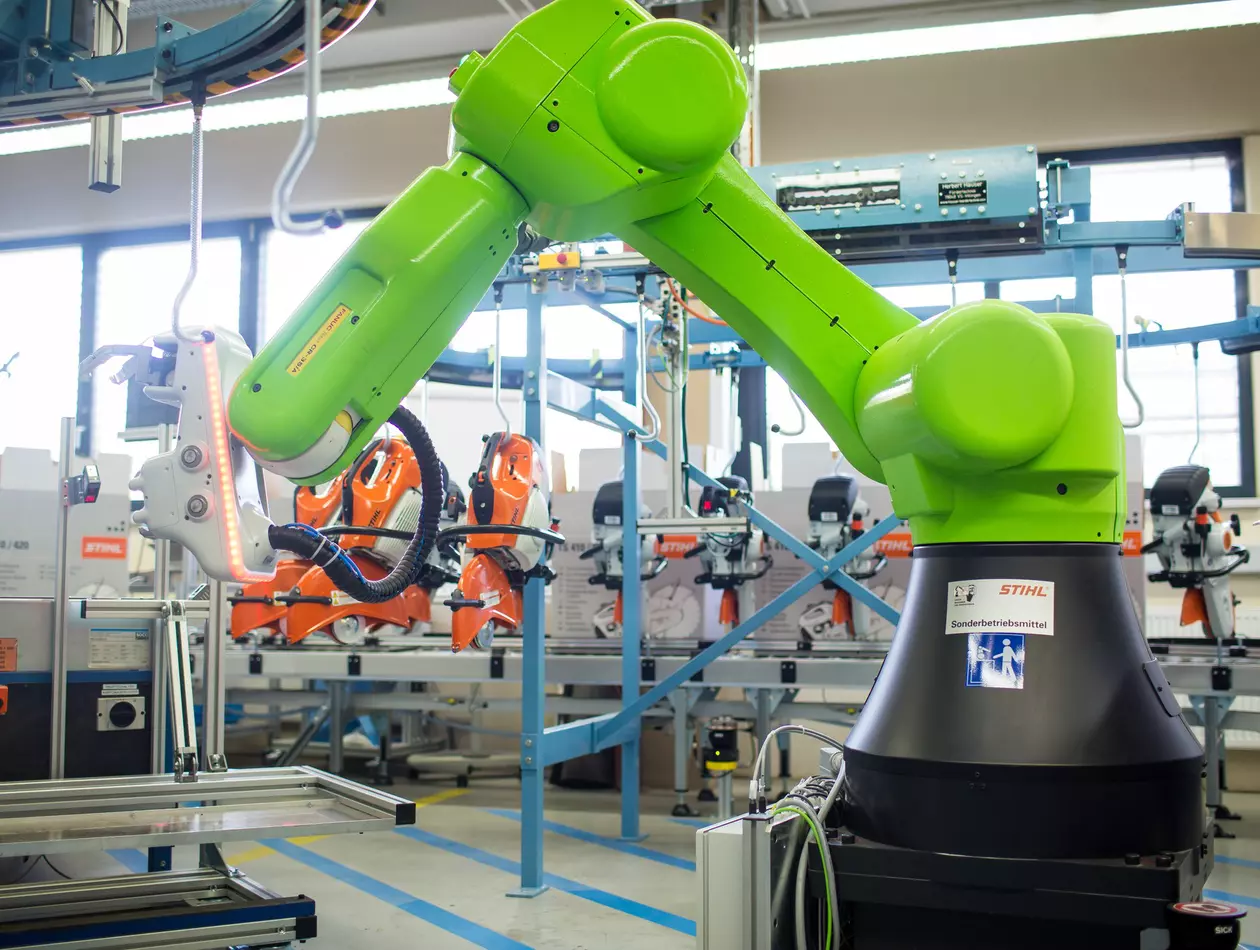

STIHL

Cobot als collega: lichter werk, betere resultaten

Kwaliteitscontroles en verpakken kunnen fysiek zwaar zijn. De integratie van collaboratieve robots kan de ergonomie van dergelijke activiteiten echter aanzienlijk verbeteren.

De perfecte match voor uw toepassing

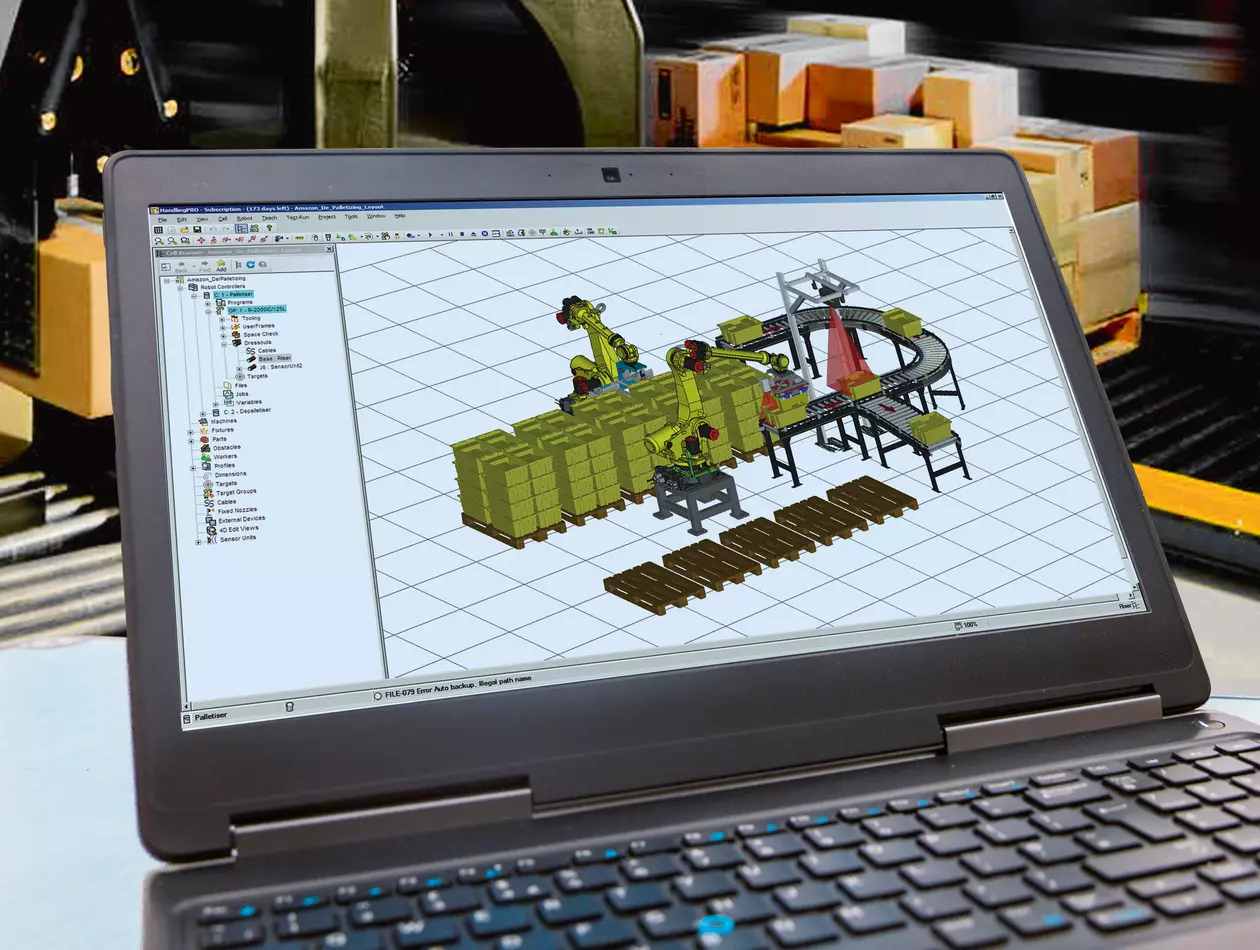

Palletiseren

Het automatiseren van uw palletiseerproces kan zowel de veiligheid als de efficiëntie van uw activiteiten verhogen. Met een breed scala aan opties waaruit u kunt kiezen, vindt u de perfecte oplossing voor verschillende formaten, ladingen, cyclustijden en precisiebehoeften, terwijl u er zeker van kunt zijn dat uw producten met de grootst mogelijke zorg worden behandeld.

Material Handling

Automatiseer uw material handling met industriële robots en ontdek tal van voordelen voor uw bedrijf. Verhoog de efficiëntie en productiviteit aanzienlijk door de tijd en inspanning van handmatige handling te verminderen. Laat robots continu en zonder vermoeidheid werken voor een constante prestatie en minimale fouten, wat resulteert in een hogere output en snellere verwerkingstijden.

Assemblage

Automatiseer uw assemblageprocessen met robots en behaal aanzienlijke voordelen ten opzichte van handmatige assemblage. Garandeer ongeëvenaarde precisie en consistentie, verminder fouten en lever constant hoge kwaliteit. Verhoog de productiesnelheid dankzij continue werking zonder vermoeidheid, wat de doorvoercapaciteit aanzienlijk vergroot. Verhoog de efficiëntie, kwaliteit en veiligheid — en maak van automatisering een strategische investering voor elke productieomgeving.

Oplossingen op maat voor uw industrie

Robots en automatisering voor de Luchtvaartindustrie

Geavanceerde robotica van FANUC: optimalisatie van productieprocessen in de luchtvaart.

Robots en automatisering voor de automotive industrie

Uitmuntendheid in de automotive sector: FANUC's veelzijdige automatiseringsoplossingen.

Elektrische voertuigen

Niemand heeft meer ervaring met het automatiseren van de productie van elektrische voertuigen dan FANUC. Vertrouw op ons om al uw EV productieprocessen te automatiseren.

Elektronica

We bieden geautomatiseerde oplossingen voor de productie van elektronica en cleanrooms.

Food & Beverage

Food & Beverages zijn onze specialiteit! Laat onze expertise in robotica uw productieproces versterken – neem vandaag nog contact met ons op.