Support Process Traceability with IIoT Solutions

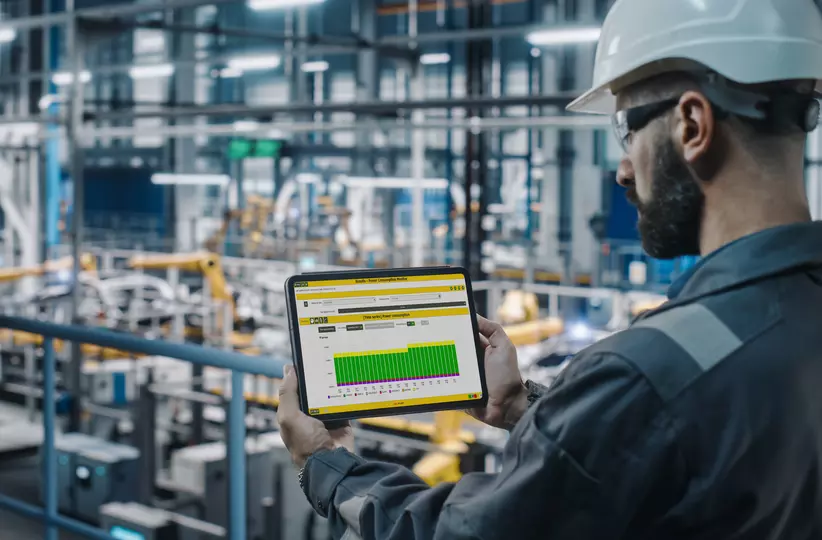

Enhance the traceability standards on your processes ensuring data-driven insights for improved operational transparency.

Maximise Visibility on Your Processes

Traceability is critical in many business areas and its improvement is an effective example of the Industry 4.0 approach. IIoT lets you collect, store and analyse production data with great effectiveness. Additionally, this data can be made available upon request of the end customer as proof of the process conditions.

Explore our portfolio of IIoT products supporting process traceability.

FANUC IIoT Products to Support Traceability

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

Monitoring

Cutting Load Monitor – PC and 𝑖HMI

Enhance the efficiency and precision of your CNC machining with our FANUC Cutting Load Monitor for PC and 𝑖HMI. This innovative solution offers real-time cutting load monitoring directly on your P...

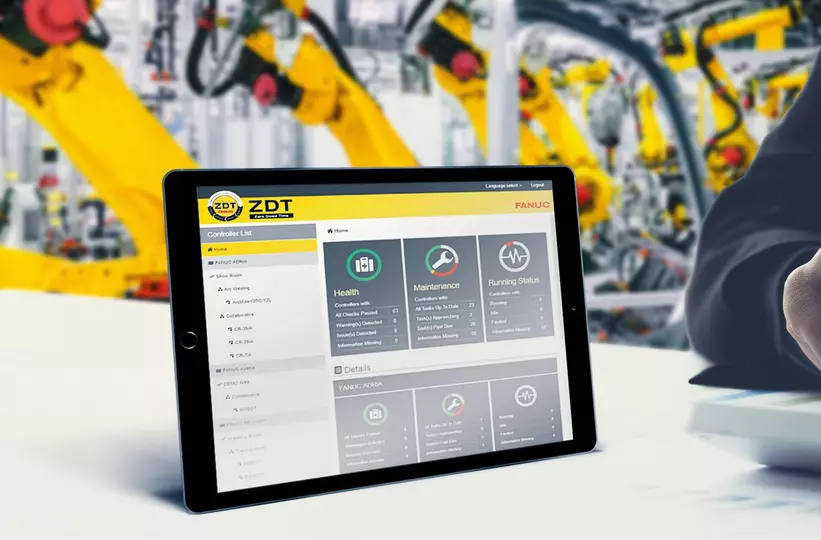

IoT Solution

ZDT (Zero Down Time)

A robot breakdown can cause significant system production down time. FANUC Zero Down Time is an IoT solution designed to eliminate unforeseen production stoppage and enhance FANUC robot performance...

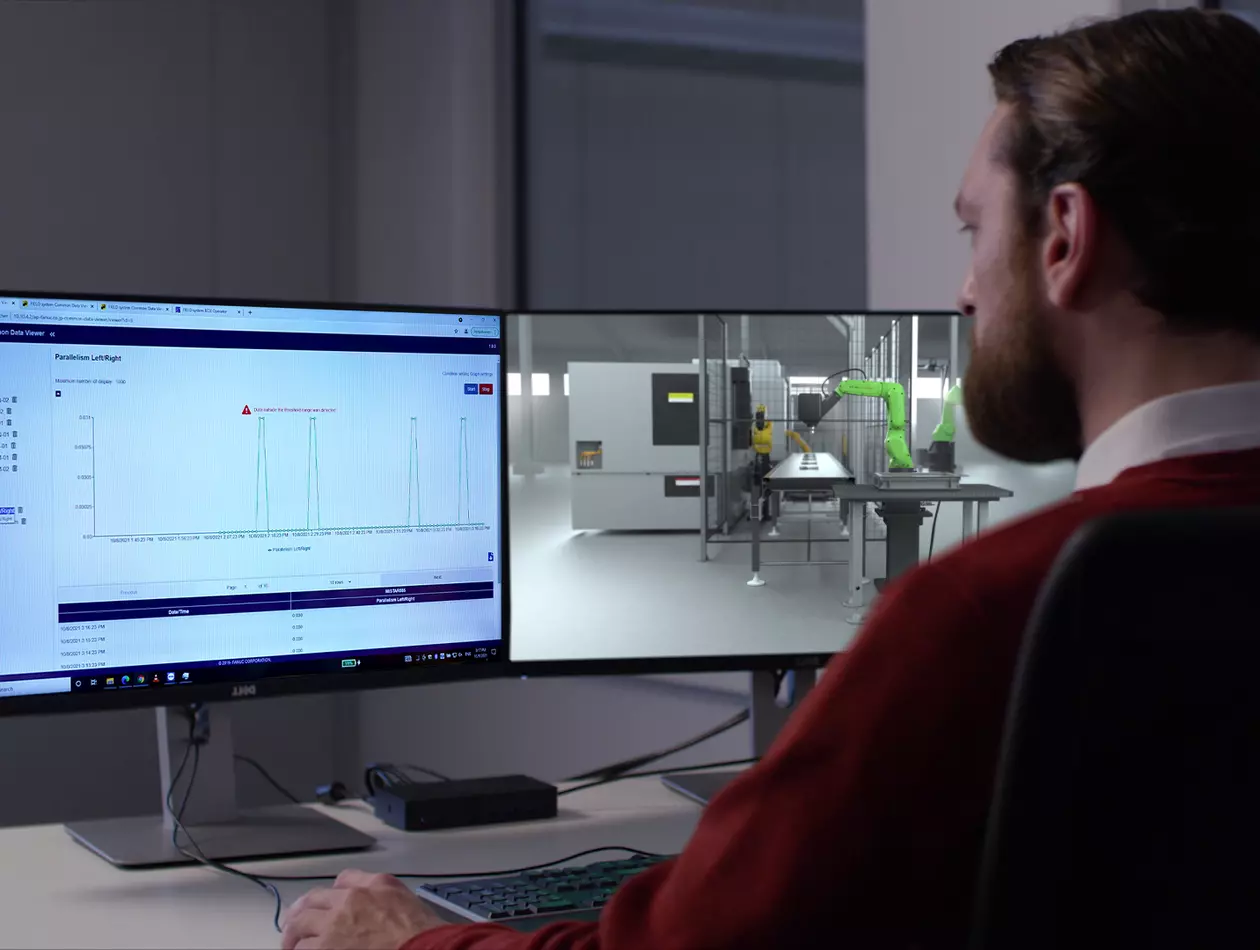

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

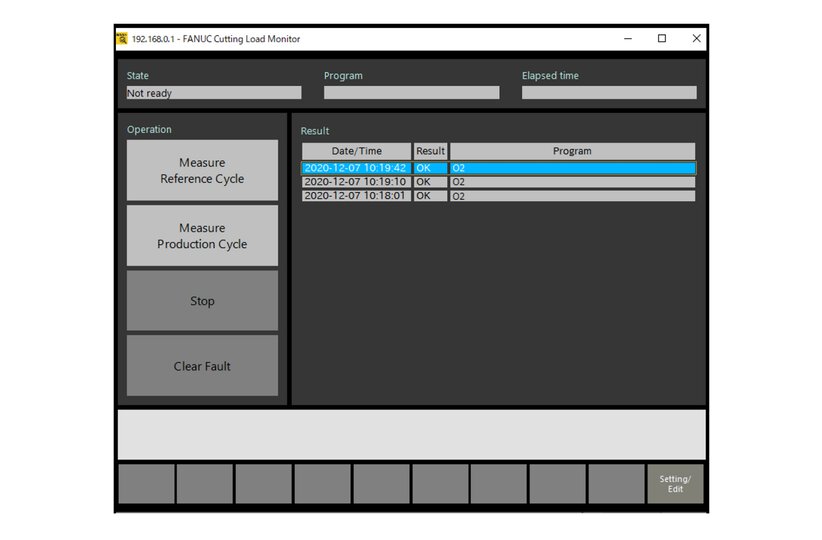

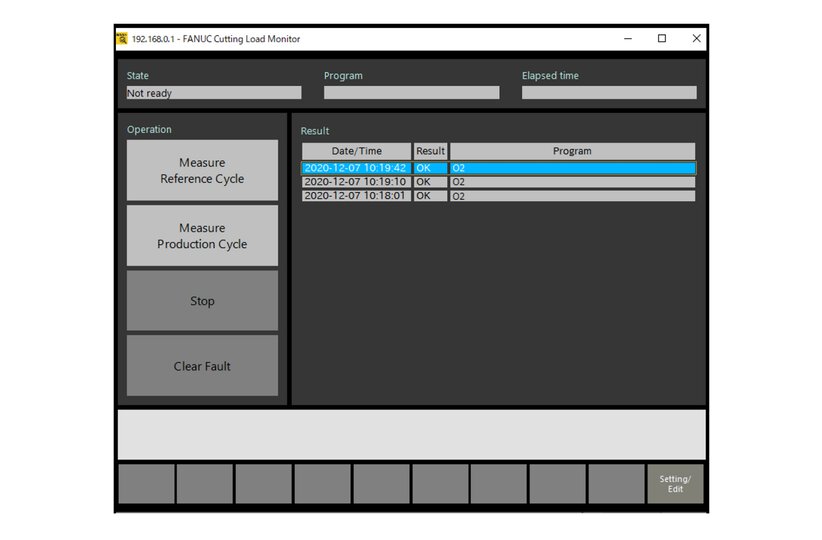

Monitoring

Cutting Load Monitor – PC and 𝑖HMI

Enhance the efficiency and precision of your CNC machining with our FANUC Cutting Load Monitor for PC and 𝑖HMI. This innovative solution offers real-time cutting load monitoring directly on your P...

Monitoring

ROBOSHOT-LINK𝑖2

Remote management of your plastic production facility - ROBOSHOT-LINK𝑖2 is a quality information management tool that allows you to visualise ROBOSHOT data. Up to 1000 ROBOSHOT machines can be con...

Monitoring

ROBOCUT-LINK𝑖

Equipped with a new graphic interface, ROBOCUT-LINK𝑖 is a production and quality information management tool that allows you to monitor the status of up to 32 ROBOCUT machines in real time from re...

Discover FANUC IIoT Solutions for Your Needs

Improving Manufacturing Performance with IIoT Solutions

Improving performance with IIoT solutions

Boosting Production Uptime with IIoT Solutions

Boosting production uptime with our advanced IIoT solutions

Optimise Energy Consumption with IIoT Solutions

Optimise energy consumption with IIoT Solutions

Improving Component Quality with IIoT Solutions

Improving component quality with IIoT solutions

Improving Process Stability with IIoT Solutions

Discover the different IIoT products in our portfolio that support production process stability