Optimisation of Costs with IIoT Solutions

Enable Cost-Effective Operations

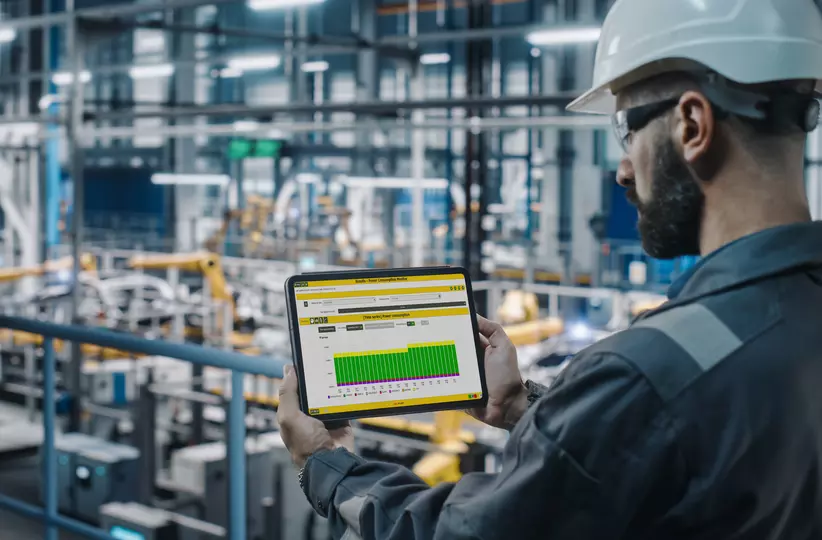

In the manufacturing industry, IIoT supports operations and processes by helping you to reduce business costs and boost profits. By connecting devices, overall maintenance costs can be lowered through the application of predictive maintenance rather reactive maintenance. In smart factories, important savings are generated by a reduction in the use of consumables, an extension of machine life and the more efficient use of energy. Furthermore, bottlenecks in production might be identified at an earlier stage, resulting in prompt remedial action.

Explore how IIoT products can support your efforts to reduce production costs.

FANUC IIoT Products to Support Cost Reduction

FIELD system Basic Package

AI Servo Monitor

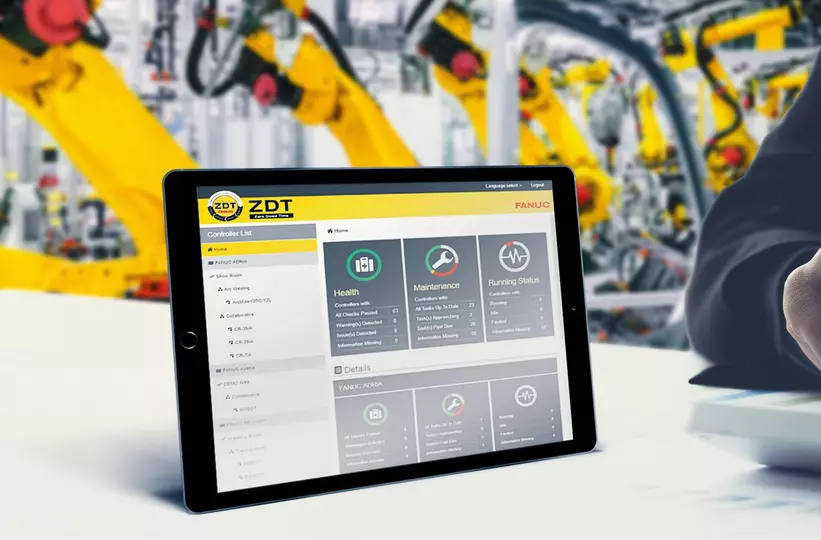

ZDT (Zero Down Time)

FIELD system Basic Package

FIELD system Basic Package

AI Servo Monitor

ROBOSHOT-LINK𝑖2

ROBOCUT-LINK𝑖

Case Studies

Trafime Leads the Field with its FANUC IIoT Platform

With business evolution and growth, many manufacturers find themselves running a disparate assortment of machinery, automation and other production systems, often supplied by many different vendors. This situation makes some production plants think that effective data management using a single IIoT platform is not possible. Well, FANUC’s FIELD system proves this thinking is misplaced, as Italy-based Trafime can confirm.

Discover FANUC IIoT Solutions for Your Needs

Improving Manufacturing Performance with IIoT Solutions

Boosting Production Uptime with IIoT Solutions

Optimise Energy Consumption with IIoT Solutions

Improving Component Quality with IIoT Solutions

Improving Process Stability with IIoT Solutions