Brunos

FANUC Robot Ends Packaging Bottleneck at Food Factory

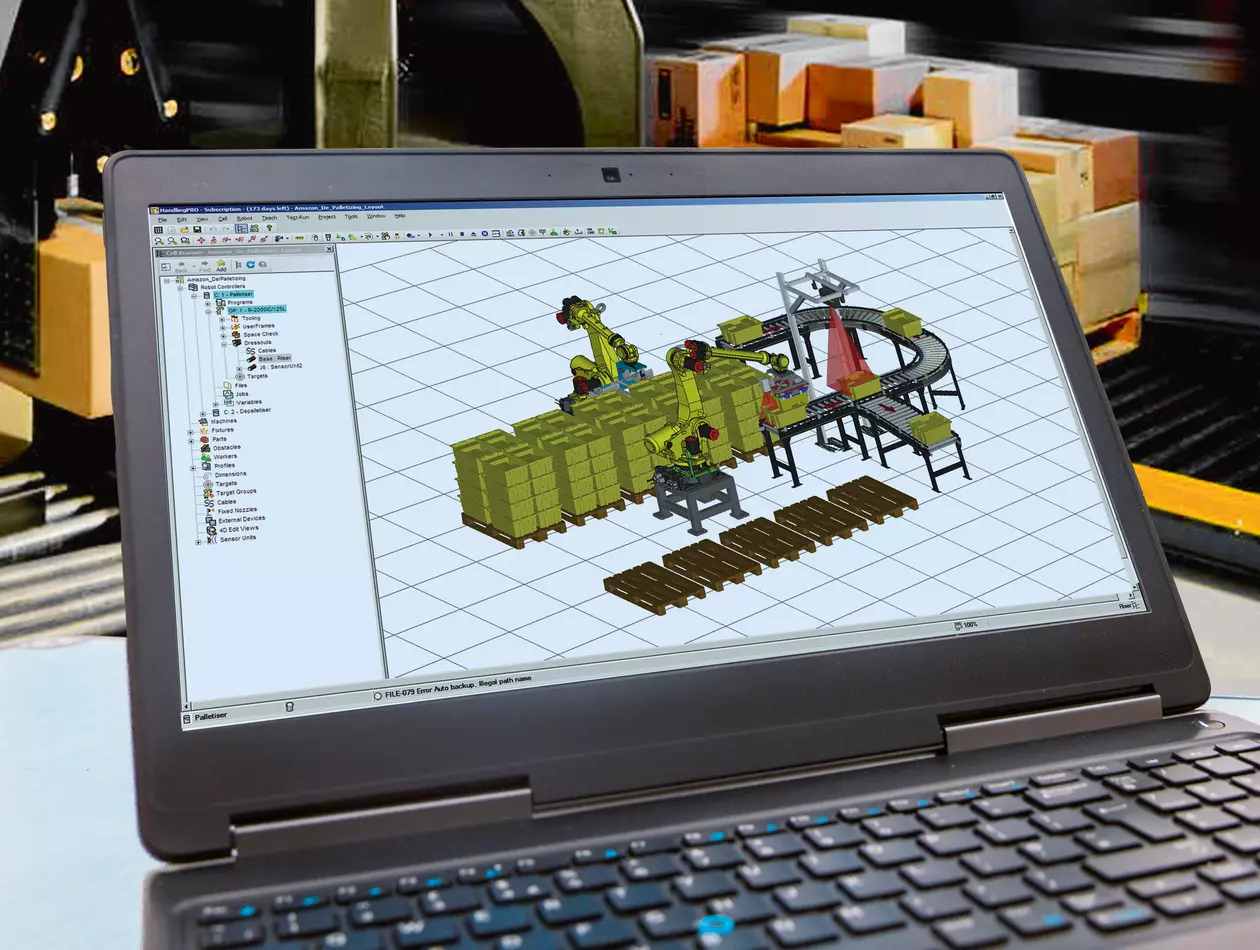

When implementing improvements to a bottleneck process the common outcome is the emergence of a new bottleneck elsewhere in the factory. Whereas in years gone by this situation would necessitate the recruitment of more labour, automation has today become industry’s go-to solution for bottlenecks. Just ask Brunos, a leading producer of salad dressings, which knows all about the benefits that a robot can bring.

Deli

FANUC M-710𝑖C/50 industrial robot enables compact solution.

Reach of > 2 metres for optimal processing of palletising pattern.

50 kg payload.

Low energy consumption and long availability of spare parts.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Paletiranje

Avtomatizacija postopka paletiranja lahko poveča varnost in učinkovitost vaših dejavnosti. S široko paleto možnosti, med katerimi lahko izbirate, boste našli popolno rešitev za različne velikosti, koristne tovore, čase ciklov in potrebe po natančnosti, vse to pa bo zagotovilo, da bodo vaši izdelki obravnavani z največjo skrbnostjo.

Hrana in pijača

Hrana in pijača sta naš kruh. Še danes se obrnite na nas, da bi naše izkušnje z industrijskimi roboti v industriji hrane in pijač delali za vas.