SCARA Series

Meet Our SCARA Series

Our family of 4-axis SCARA robots includes models with payloads up to 20 kg and a reach up to 1,100 mm. Dedicated models come with a white epoxy coating, IP54, NSF-H1 food-grade grease and anti-rust bolts, making them an ideal choice for food and cleanroom applications.

Get Inspiration from Others' Success

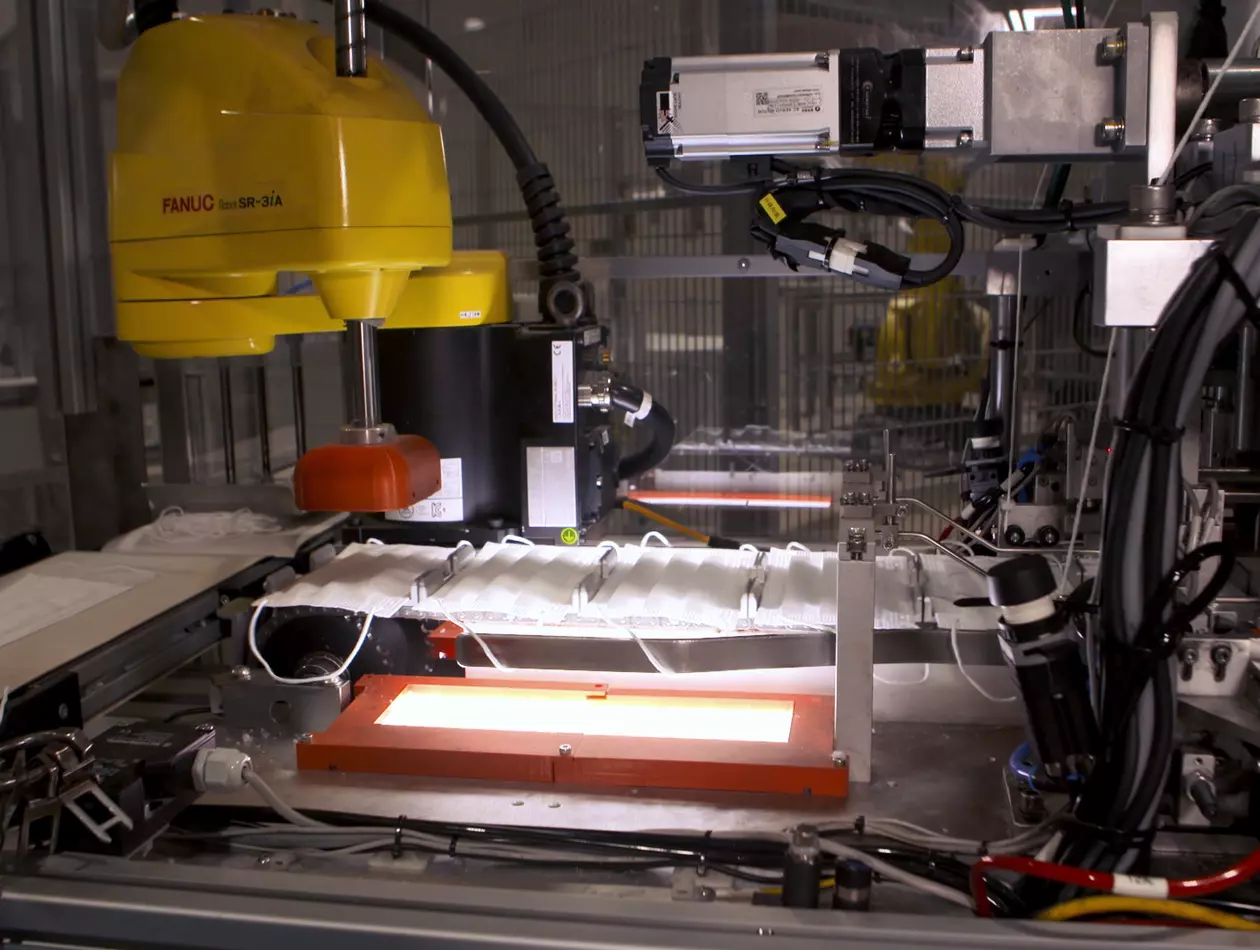

FANUC Robots Help Mask Producer Face up to the Challenge

When production demand accelerates dramatically in a short space of time, robots and automation can help meet requirements much faster than many realise. However, this outcome depends heavily on the selection of robots that are easy to install, program and commission.

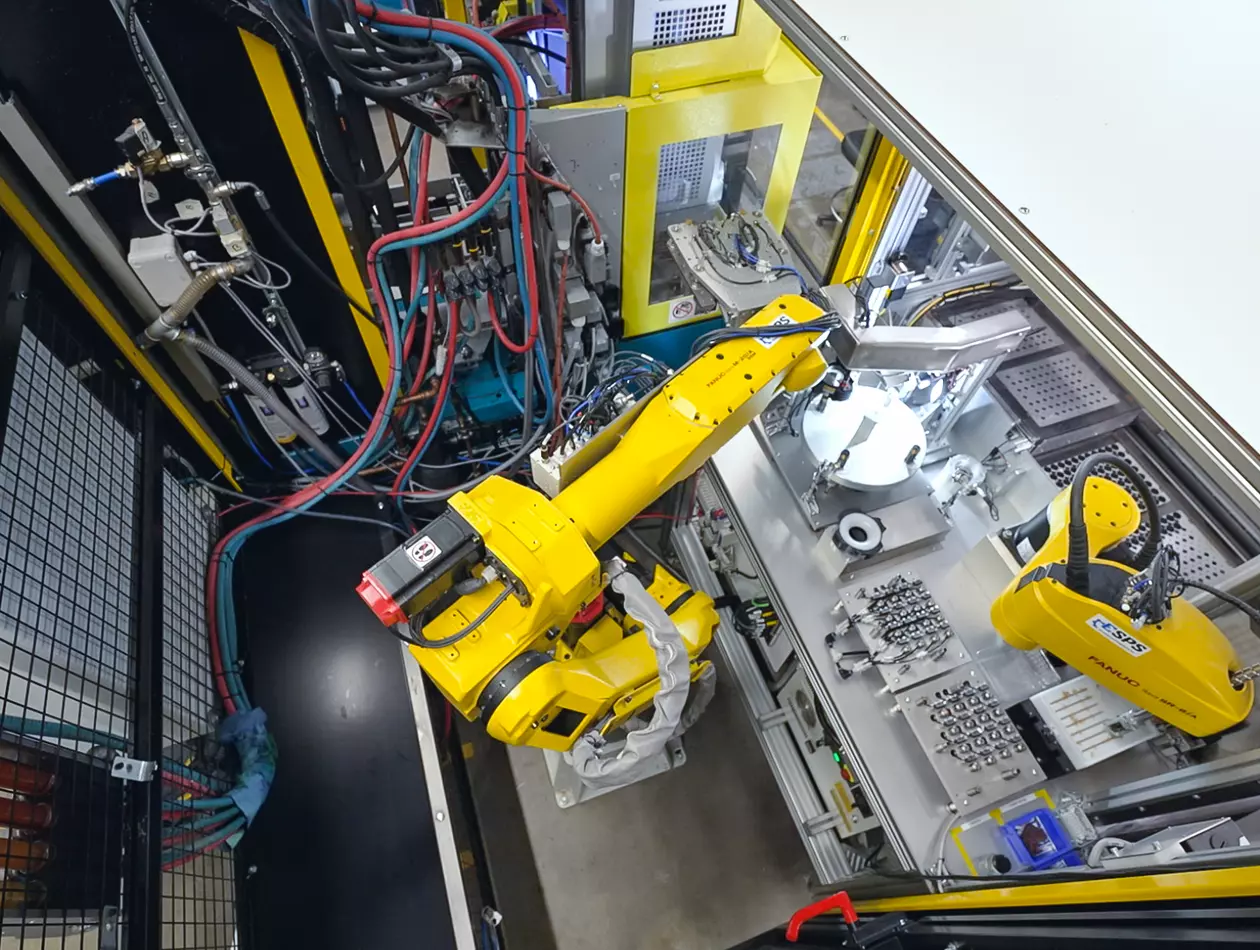

Placing Plastic Injection-Moulding into Packing Trays

Because manufacturers everywhere face shortages of skilled labor, and as a company dedicated to excellence, Kunstoff-Packungen continuously seeks ways to improve its level of automation.

Loading & Unloading, Flex Feeding, and Inspection in a Single Cell

Vernay is globally renowned for flow control solutions, producing over a billion rubber valve components annually across Asia, the Americas, and Europe. Their critical products, used in devices like respirators and EV battery systems, must meet the highest quality standards with zero defects.

Perfect Fit for Your Application

Assembling

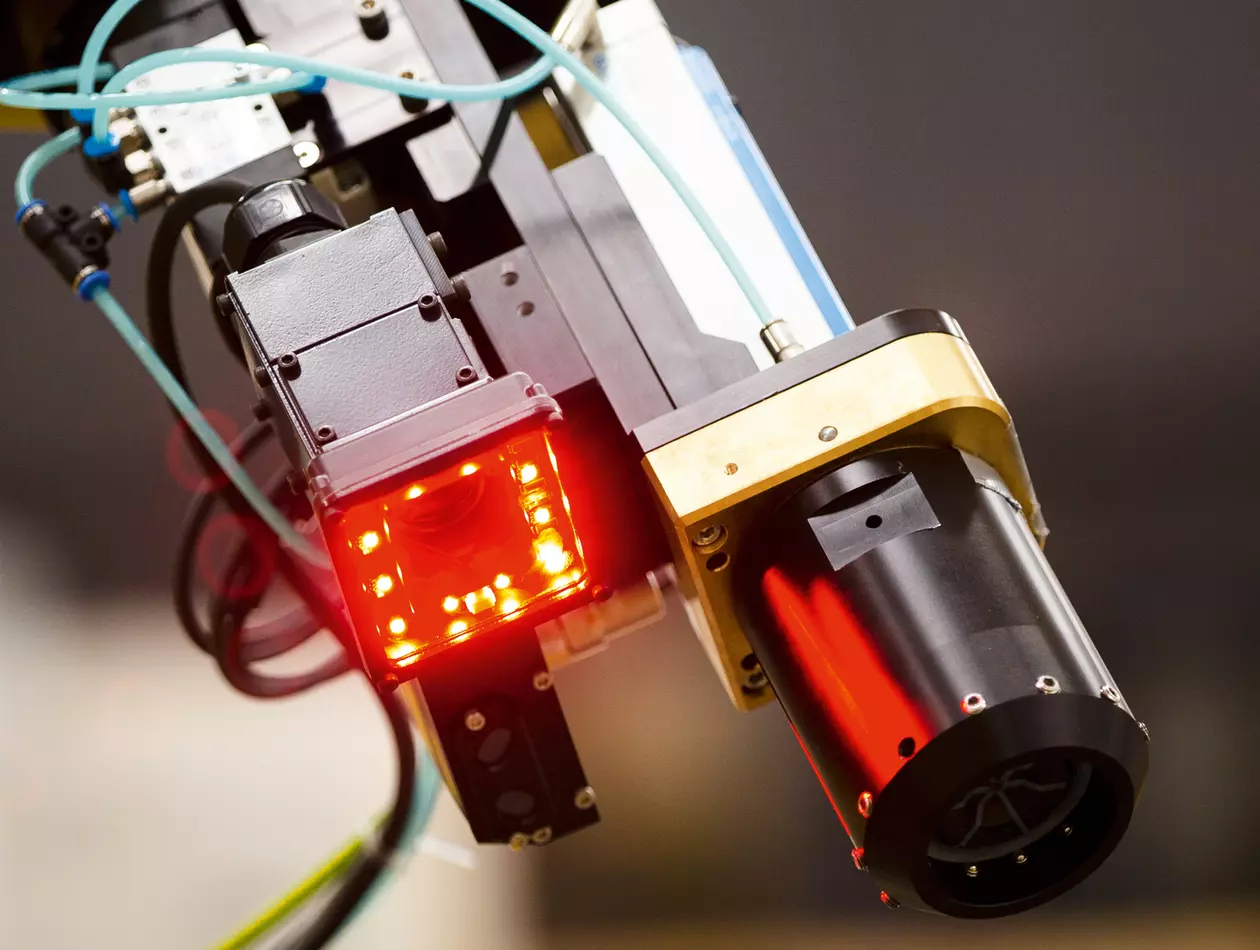

Vision Inspection

Material Handling

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

Robotics & Automation for the Automotive Industry

Electric Vehicles

Electronics

Food & Beverage

Robotics & Automation for the Medical Industry