FAMAR

FANUC Cobot Brings Flexibility to Vertical Lathe Operations

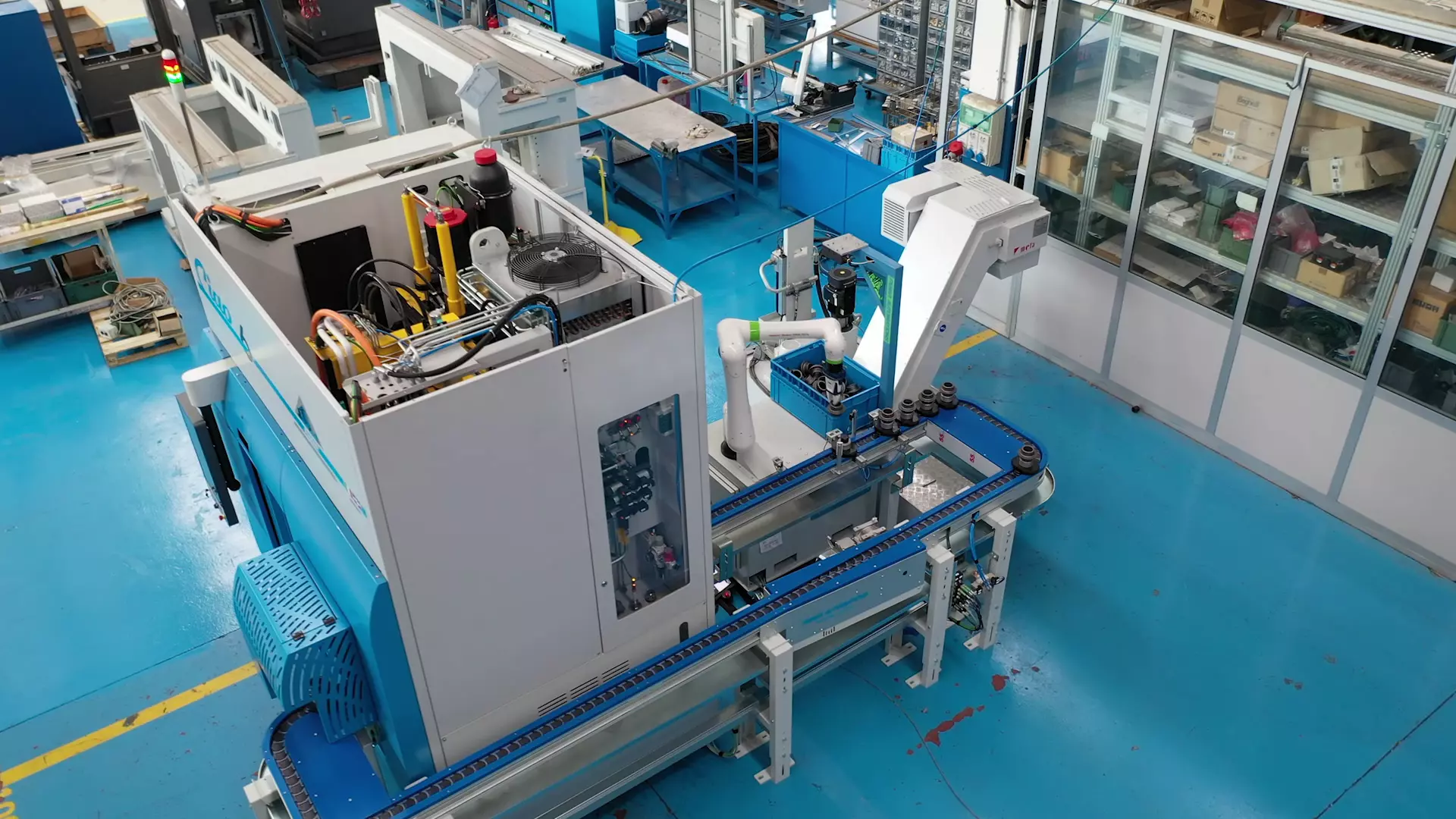

Famar, an Italian builder of vertical lathes, has integrated a bin picking system enabled by a FANUC collaborative robot (cobot) into its recently developed Ciao 6 machine. The system facilitates the recognition, picking and handling of parts from tote bins to and from the machine’s conveyor, making the application flexible and adaptable to different components.

Material Handling CNC TurningRobotics & Automation for the Automotive IndustryComplex Machining for the Automotive Industry

Share

FANUC CRX-10𝑖A cobot offers highly functional motion.

FANUC 0𝑖-TF CNC shortens lathe cycle times and boosts surface finish.

Fully customisable HMI with FANUC’s open system approach.

FANUC global service gives peace of mind to both machine builders and end users.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!