Solutions for the Machine Tool Industry

Despite the current global investment restraint, FANUC expects a significant increase in demand for factory automation over the medium-to-long term, including in Europe. At the recent EMO 2023 exhibition in Hanover, the company showcased its latest products and solutions, demonstrating how machine tool manufacturers and users can address pressing issues such as rising energy costs, digitalisation and skills shortages.

Among the most important innovations was the new CNC generation, which although still under development, made its world premiere at EMO. Equipped with a modern 𝑖HMI2 interface, the new FS500-𝑖A provides significantly higher performance, support for any machine kinematics and better clarity for the operator. Users can also achieve energy savings of around 10 percent thanks to the new 𝛼𝑖-D drive system. FANUC has in fact already implemented many of these benefits in the improved versions of its existing FS30𝑖/31𝑖/32𝑖-B Plus and standard FS0𝑖-F Plus CNC solutions.

In the area of digitalisation, FANUC offers several added-value solutions, including digital twin technology that helps with the development of machine software and manufacturer-specific operator guidance. Digital twin technology can also serve to optimise performance, streamline operations and test new concepts, all mapped virtually but very realistically in support of fast implementation.

FANUC Showcases Integrated IoT Solutions and Advanced Automation

When it comes to data acquisition and analysis, FANUC can provide numerous integrated IoT solutions, as well as the company's IoT platform FIELD System Basic Package. In addition, FANUC offers interfaces to all major IoT platforms, an important prerequisite in the smart factory journey. To demonstrate the easy integration of FANUC products - CNC, robots and ROBOMACHINES (together with peripherals) - into a fully automated factory, the company showed an efficient production cell at EMO with two ROBODRILL 𝛼-D𝑖B Plus series machining centres and two ROBOCUT 𝛼-C𝑖C wire EDM machines.

Highlights of FANUC's machine range presented at EMO included the ROBODRILL 𝛼-D28L𝑖B5ADV Plus Y500 with an automatic tool-change capacity of 28 stations and a longer Y-axis stroke of 500 mm. Also on display was the ROBOCUT 𝛼-C800𝑖C wire EDM machine, which completes the series as the largest FANUC C𝑖C model with improved precision and ease of use. The ROBOSHOT 𝛼-S50𝑖B injection moulding machine, which is an all-electric model offering particularly low energy consumption, featured support from a FANUC LR Mate series robot to demonstrate fully automated operation.

While machine tool automation has been an important sales driver for FANUC in recent years, robots have also found their way into factories, logistics centres and other places, performing a wide range of applications. An increasing number feature vision systems that require high computing power. At EMO, FANUC introduced its new 𝑖PC Box, which is a reliable industrial solution for advanced robotic applications.

FANUC Showcases Versatile Robots and Expands Cobot Capabilities

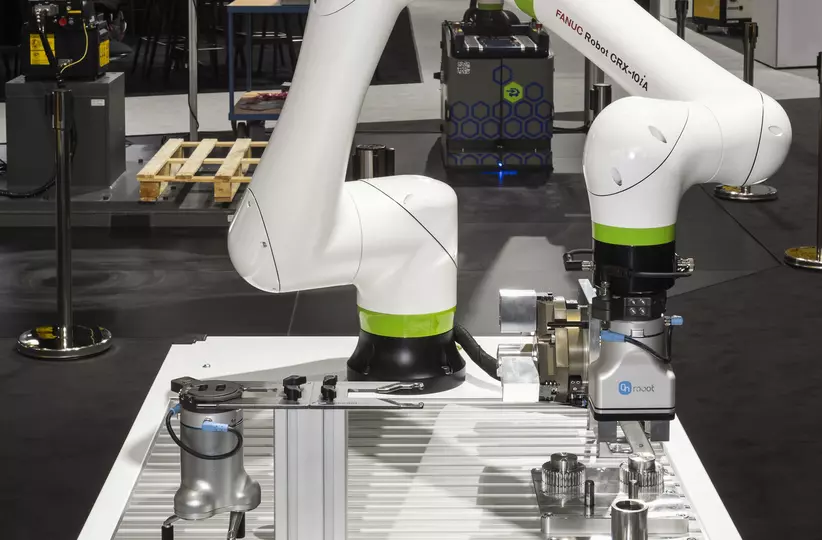

The company, which has more than 200 robot models in its range and recently announced the delivery of its one millionth robot, exhibited a number of robots in a variety of interesting applications. Eye-catchers included the world's most powerful robot, the M-2000𝑖A/2300, which can handle payloads of up to 2300 kg, and the M-1000𝑖A with a payload of 1000 kg. Both attracted much attention with their highly versatile movements, as did FANUC's extensive range of collaborative robots (cobots).

FANUC recently extended the payloads of its cobots to 30 kg for the CRX-25𝑖A and 50 kg for the CR-35𝑖B, making the latter model the most powerful cobot on the market. The demand for cobots has increased dramatically in recent years, as they integrate easily into existing production lines without the need for safety barriers or guarding, thus saving space and providing the ability to work 'hand in hand' with factory operatives.

"We want to relieve workers of repetitive, boring and dangerous tasks," Marco Ghirardello, president and CEO of FANUC Europe, told a press conference at EMO. "Workers and companies alike can benefit by reassigning their employees to more challenging tasks where they can better use their cognitive skills." To help companies upskill their employees, FANUC has expanded its training centres and academies across Europe. The company is also working with universities and educational institutions to train the next generation of automation experts.

FANUC's pursuit of innovation, training, reliable products and service, alongside its large sales and service network of more than 20 offices in Europe and over 260 worldwide locations, seems to be paying off. "In Europe, we are currently seeing many customers looking to expand outside their home markets and choosing us as a global partner," Ghirardello said. He also announced that FANUC would continue to work closely with customers and maintain its strategy of developing innovative solutions for the betterment of the manufacturing industry.

Other News

Developing Robots with Empathy

Robots Repair Railway Tracks

European Championship for Young Robot Experts

FANUC to Provide Glimpse of Future CNC Platform at EMO Hannover 2023

Young Robot Integrators in the Spotlight

Sustainability, Energy Efficiency and Reliability at Heart of FANUC FAKUMA Display

FANUC Ships its One-Millionth Robot

Solutions for the Machine Tool Industry

FANUC and Volvo Cars Sign Global Contract

Award for Climate Friendliness

FANUC Honoured as Top Innovator 2024

FANUC Drives Machines to Peak Performance

WorldSkills and FANUC Promote Next-Generation Robot Experts