Le service clientèle par des services durables

La promesse de FANUC

Chez FANUC, nous croyons au service avant tout.

Ce n'est pas seulement un slogan. C'est un engagement envers vous, notre précieux client, que FANUC fournira une assistance à vie sur nos produits, assurant la disponibilité des pièces de rechange et un service d'assistance local dans le monde entier.

Faites confiance à notre promesse et lancez-nous un défi !

Où que vous ayez besoin de nous, nous sommes là pour vous

Assistance 24/7

Améliorez l'efficacité opérationnelle

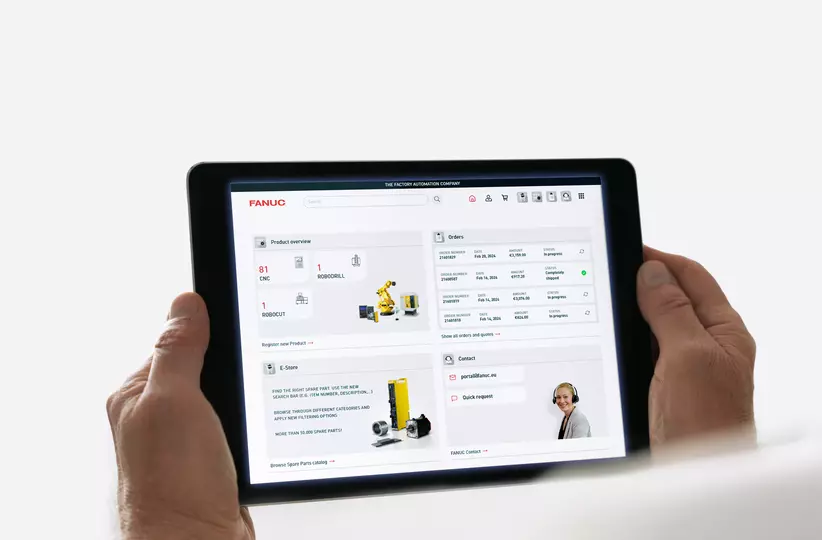

Support technique à distance

Trouvez la formation qui vous convient

Une forte présence locale

Daniel Streit

Directeur capsa Suisse

Nous prenons soin de vos produits aussi longtemps qu'ils sont utilisés

Nous concevons et fabriquons des produits conçus pour durer.

Nous assurons une maintenance à vie en nous engageant à fournir des pièces de rechange pendant toute la durée de vie opérationnelle de vos produits. Chez FANUC, notre engagement ne s'arrête pas à l'achat initial. Nous fournissons un système d'assistance complet qui garantit que votre équipement FANUC reste opérationnel et efficace tout au long de son cycle de vie. Nous sommes votre partenaire fiable pour une assistance complète et la meilleure expérience client.

FANUC.

01 | Conçu pour une utilisation à long terme

La qualité, la performance et la fiabilité sont au cœur du développement des produits FANUC.

02 | Services préventifs et prédictifs

Éviter les arrêts de production et augmenter l'efficacité globale

03 | Assistance à distance avec la réalité assistée de FANUC

Permet une réponse rapide et réduit les déplacements

04 | Entretien à vie

Des pièces de rechange et une assistance locale solide, pour réduire les déchets et les émissions - aussi longtemps que votre produit est utilisé.

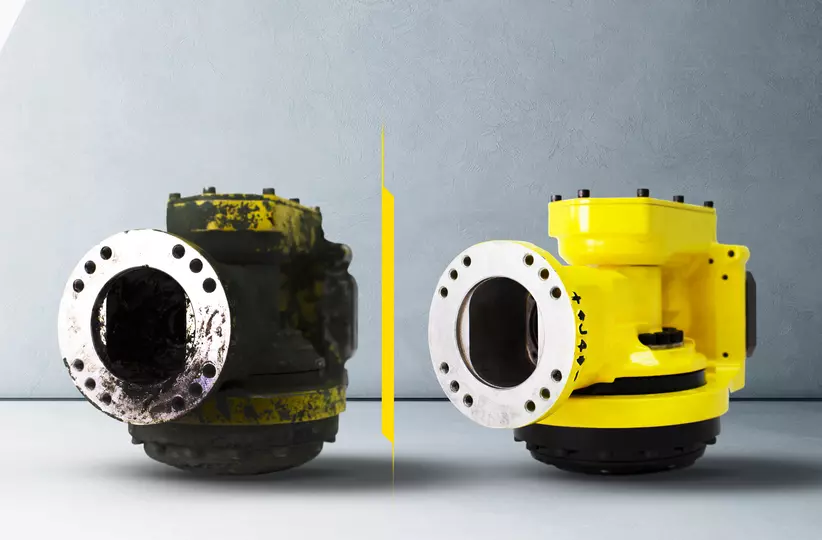

05 | Pièces de rechange remises à neuf

Comme neuf, de qualité 100 % OEM et respectueux de l'environnement

06 | Programme de régénération

Donnez une nouvelle vie à vos produits FANUC et optimisez leur valeur

Soutenir votre entreprise grâce à notre réseau mondial d'entrepôts

Toutes les pièces de rechange, quand et où vous en avez besoin grâce à notre réseau de plus de 20 entrepôts interconnectés en Europe et dans le monde, garantissant une expédition 24 heures sur 24 et 7 jours sur 7. Une excellente disponibilité des pièces pour un temps de fonctionnement maximal.

FANUC Autriche

Gewerbestrasse 1 AT-4655 Vorchdorf AUTRICHE Courriel : service@fanuc.at

FANUC Adria

SLOVENJA | CROATIE | BOSNIE-HERZEGOVINE | MONTENEGRO | KOSOVO Ipavčeva 21 3000 Celje SLOVÉNIE Courriel : parts@fanuc.si

FANUC Benelux

BELGIQUE | LUXEMBOURG | PAYS-BAS Oude Baan 3F (B - zone rouge) 2800 Malines BELGIQUE Courriel : parts@fanuc.be

FANUC Bulgarie

BULGARIE | ALBANIE | CHYPRE | GRECE | REPUBLIQUE DE MACEDOINE DU NORD 467 "Okolovrasten pat" (Parc logique STAD) BG-1588 Sofia BULGARIE Courriel : spareparts.bg@fanuc.eu

FANUC République tchèque

K Bílému vrchu 3142/7 193 00 Praha 9 - Horní Počernice RÉPUBLIQUE TCHÈQUE Courriel : parts.cz@fanuc.eu

FANUC France

FRANCE | ALGERIE | EGYPTE | MONACO | MAROC (ABS BUSINESS) | TUNISIE ZAC des Folies 15, rue Léonard de Vinci 91090 Lisses FRANCE Courriel : parts@fanuc.fr

FANUC Allemagne

Bernhäuser Str. 36 D-73765 Neuhausen a.d.F. ALLEMAGNE Courriel : e-teile@fanuc.de

FANUC Hongrie

Torbágy utca 7. HU-2045 Törökbálint HONGRIE Courriel : info@fanuc.hu

FANUC Irlande

Unité 1 dans l'unité K8 Maynooth Business Campus Comté de Kildare IRLANDE Courriel : parts@fanuc.ie

FANUC Israël

HaMelacha St. 14, Park Afek Rosh Ha'Ayin 4809135 ISRAËL Courriel : spareparts.il@fanuc.eu

FANUC Italie

ITALIE | MALTE | SAINT-MARIN | VATICAN Via Lodi, 13 20020 Lainate (MI) ITALIE Courriel : ricambi.it@fanuc.eu

FANUC Nordique | SE

SUÈDE | ESTONIE | LETTONIE | LITUANIE | NORVÈGE Djurhagegatan 10 S-213 76 Malmö SUEDE Courriel : parts@fanuc.se

FANUC Pologne

ul. Sakury 2 51-117 Wrocław POLOGNE Courriel : czesci@fanuc.pl

FANUC Roumanie

ROUMANIE | MOLDAVIE Ferma 9, Hala 25 407280 Floreşti, jud. Cluj ROUMANIE Courriel : info@fanuc.ro

FANUC Serbie

Kralja Petra I Karađorđevića 92a 22330 Nova Pazova SERBIE Courriel : parts@fanuc.rs

FANUC Slovaquie

Pri Jelšine 4851/5 949 01 Nitra SLOVAQUIE Courriel : service.sk@fanuc.eu

FANUC Suisse

SUISSE | LIECHTENSTEIN Grenchenstrasse 7 2504 Biel/Bienne SUISSE Courriel : parts@fanuc.ch

FANUC Turquie

TURQUIE | ARMENIE | AZERBAÏDJAN | GEORGIE | KAZAKHSTAN | REPUBLIQUE KIRGHIZE | TAJIKISTAN | TURKMENISTAN | OUZBEKISTAN Eyüp Sultan Mahallesi Gülibrişim Sokak No : 2 Sancaktepe/İstanbul TÜRKİYE Courriel : parts.tr@fanuc.eu

FANUC Royaume-Uni

ROYAUME-UNI | ISLANDE Sapphire Way, Ansty Coventry CV7 9DR ROYAUME-UNI Courriel : parts@fanuc.co.uk

FANUC Ukraine

Stolychne hwy 100 03680 Kyiv UKRAINE Courriel : info@fanuc.ua

FANUC Europe

7, rue Benedikt Zender 6468 Echternach LUXEMBOURG

FANUC France

ZAC ecotec Marnaz 628 Avenue des amaranche 74460 Marnaz FRANCE Courriel : parts@fanuc.fr

FANUC Nordique | FI

Äyritie 12A, Porte 8 FI-01510 Vantaa FINLANDE Courriel : parts@fanuc.se

FANUC Nordique | DK

Syddanske Forskerparker, Forskerparken 10 DK-5230 Odense M DANEMARK Courriel : parts@fanuc.se

FANUC Iberia | ES

ESPAGNE | ANDORRE | MAROC (Base Business) C/Danubi 12-16 08174 Sant Cugat del Vallés (Barcelona) ESPAGNE Courriel : recambios@fanuc.es

FANUC Iberia | PT

Rua Professor David Martins, 148 4485-805 Vila do Conde PORTUGAL Courriel : recambios@fanuc.es

Aitor Zumarraga

Directeur général cmz, Espagne

Découvrez les solutions de service FANUC

Terrain et maintenance

Support technique à distance

Pièces de rechange

Remise à neuf