Tesy

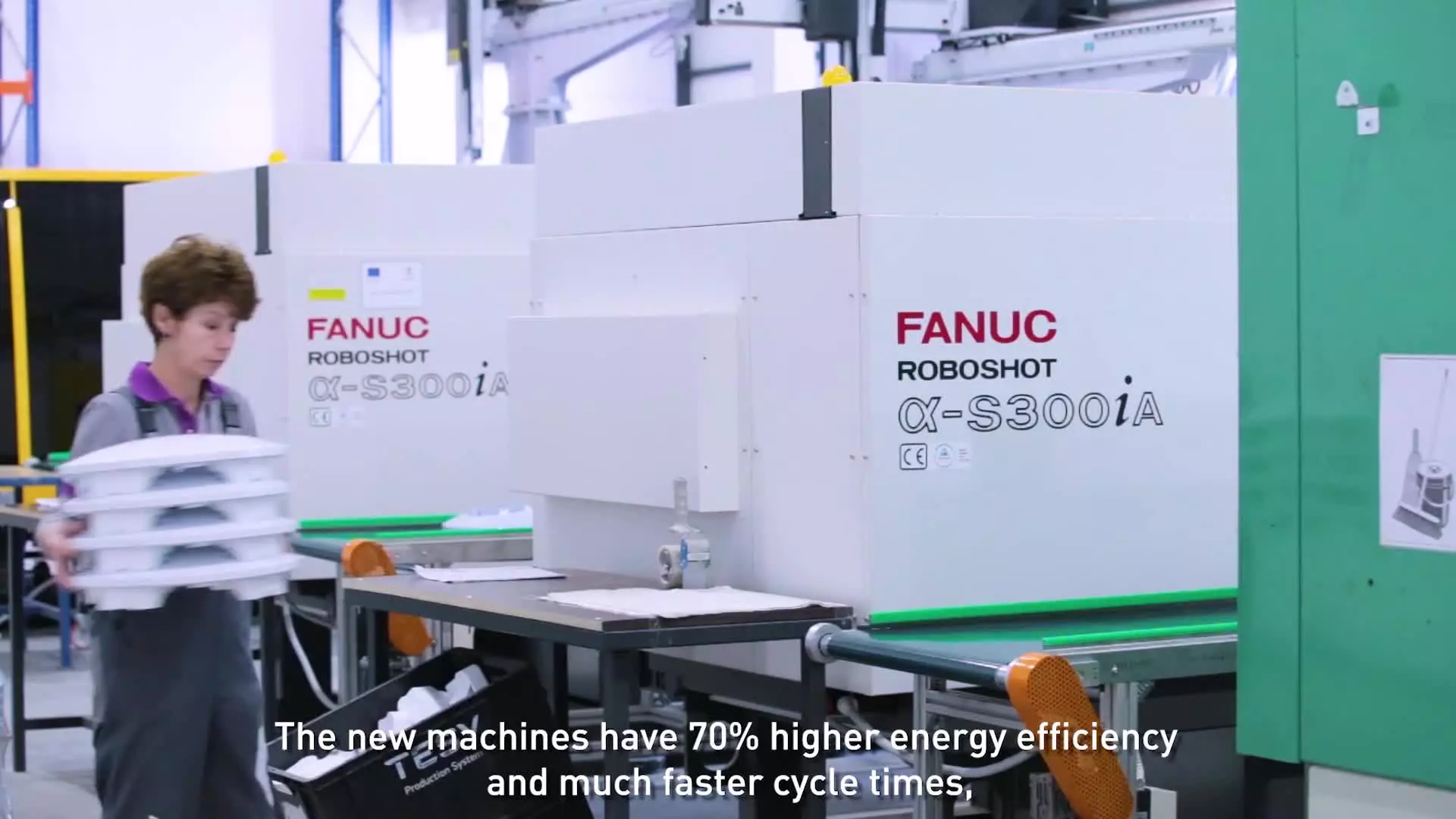

TESY on the Road to Efficiency With ROBOSHOT

High production efficiency, low energy costs and noise emissions bundled with great technical support and service is what customers can expect from FANUC’s ROBOSHOT fully electric injection moulding machine.

Share

Faster production cycle improving machine capacity.

Energy efficiency improved by over 70%.

Low noise levels improving working environment.

Great support and service from FANUC.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Injection Moulding

Injection moulding is a highly efficient manufacturing process that enables the production of complex, high-quality plastic components with precision and consistency. Utilising advanced automation and robotics, this technology is essential for industries requiring large-scale production, ensuring cost-effective solutions without compromising on the integrity or performance of the final product.