CNC Systems - Everything Under Control!

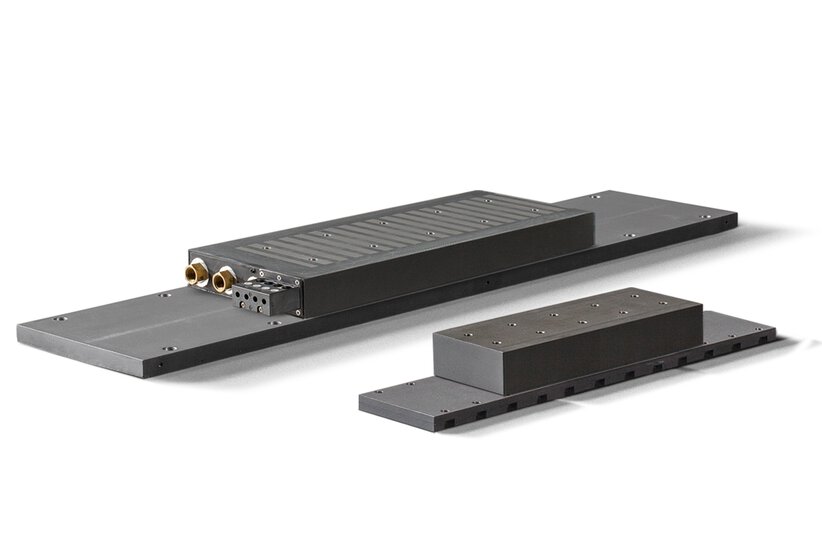

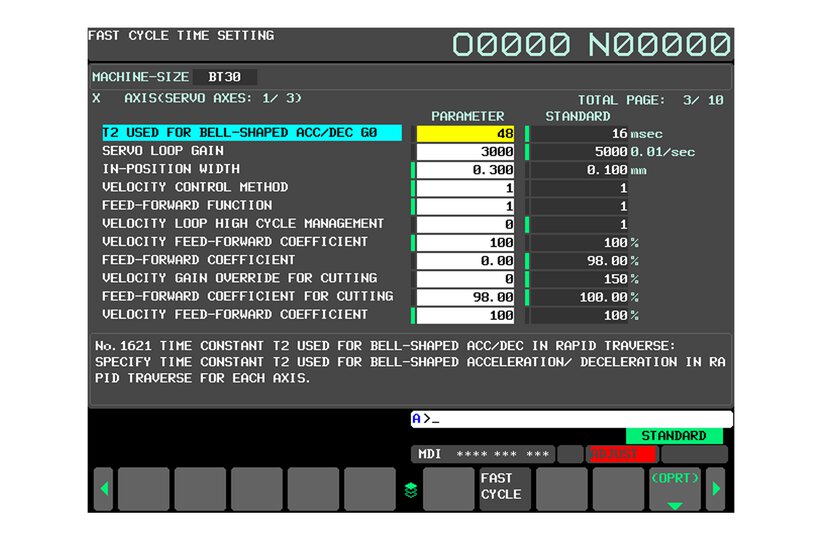

Discover our precision CNC series, Power Motion 𝑖-A Plus, and drives. Explore our versatile 0𝑖-F Plus series and the high-end 30𝑖/31𝑖/32𝑖-B Plus series, both covering a wide range of applications. Enhance performance with advanced CNC options, customise with specialist software and optimise production with IoT solutions. Use FANUC Retrofit solutions to upgrade your existing systems. Empower your team with training resources and seamless integration. Discover how our CNC products can transform your manufacturing capabilities.

Find the Ideal FANUC CNC Model for Your Manufacturing Needs

From premium standard and advanced machining CNCs to models specifically designed for the motion control market, the 30𝑖/ 31𝑖/ 32𝑖 Model B Plus Series, 0𝑖-F Plus Series and Power Motion𝑖-A Plus offer one of the widest ranges of CNCs and associated options and accessories.

Use our CNC Finder tool to find the right FANUC CNC for you.

Get Inspired

Perfect Fit for Your Application

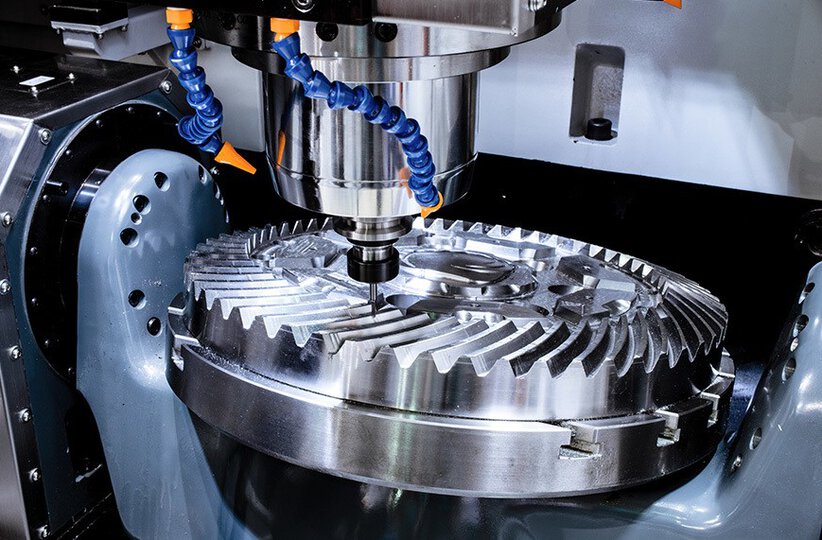

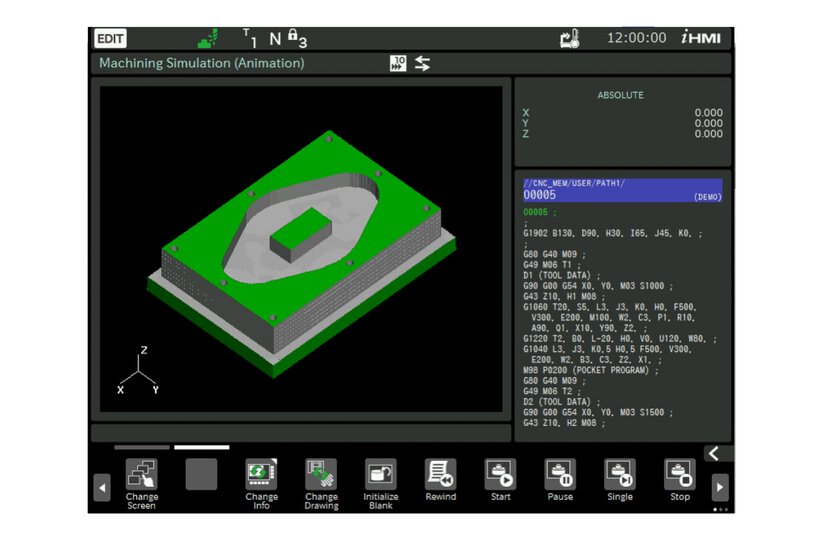

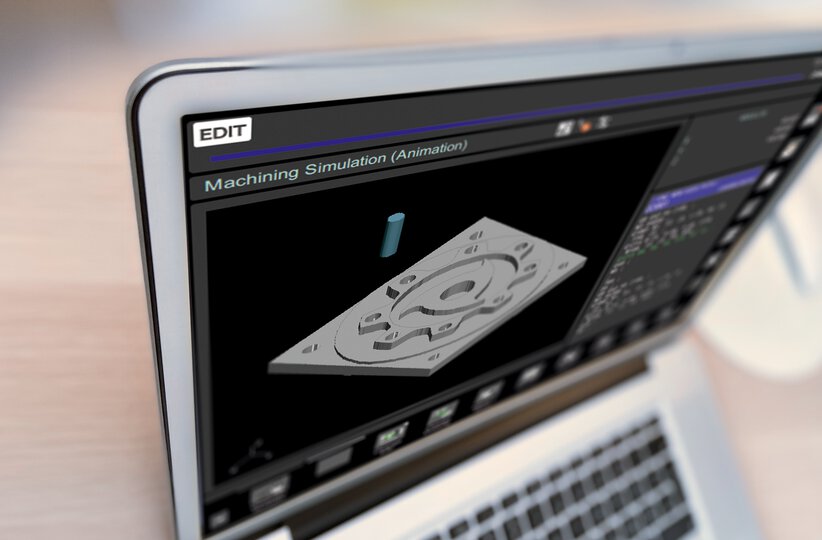

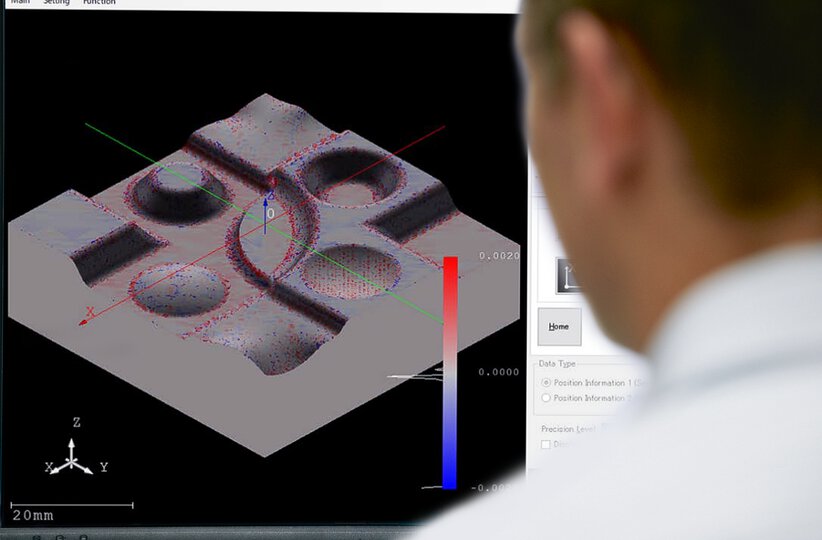

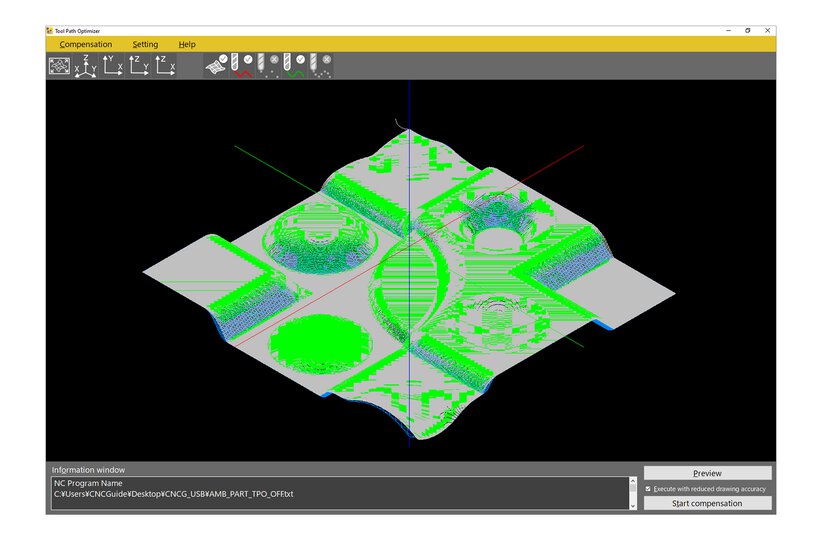

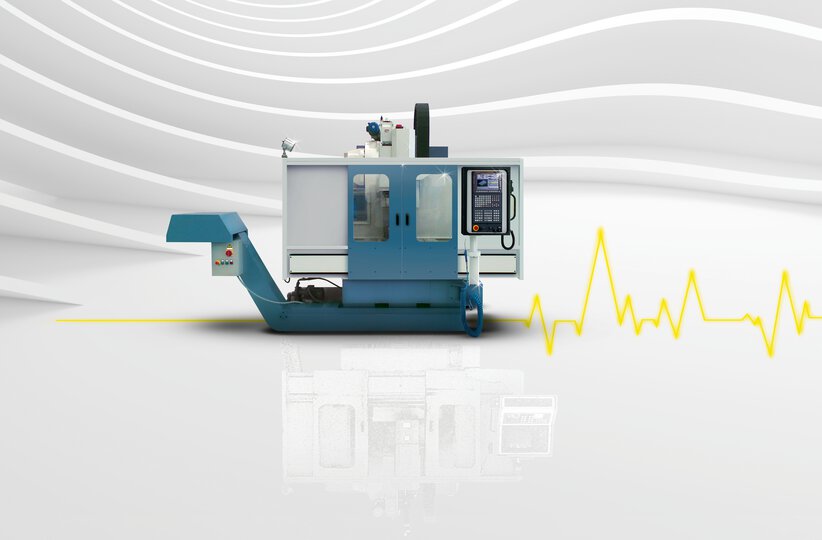

CNC Milling

CNC milling is a machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece to create a desired shape. It is widely used for producing precision parts with complex geometries. The process involves securing the workpiece on a movable table and using various tools to cut, drill, and shape the material based on programmed instructions.

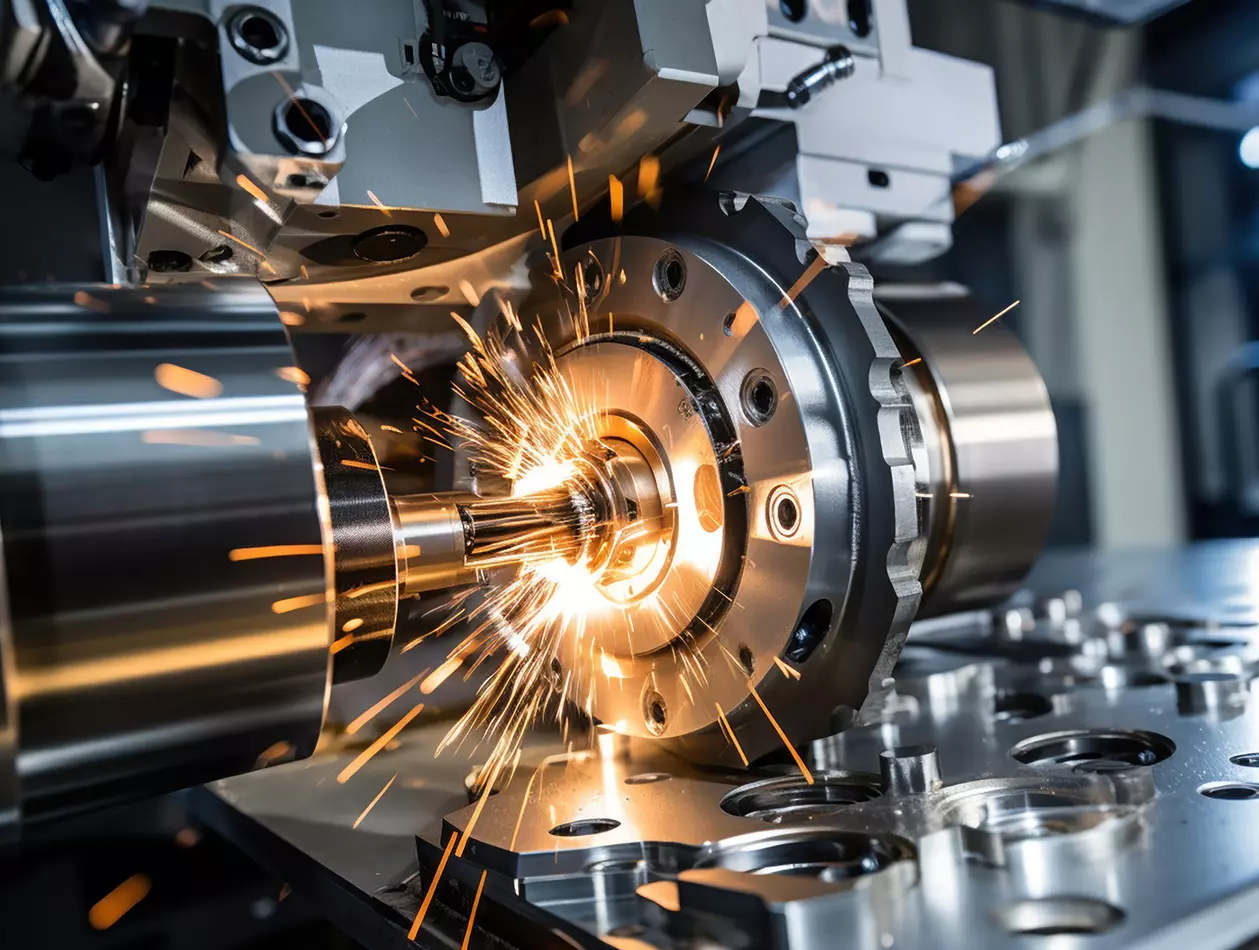

CNC Grinding

Grinding is a precision machining process using an abrasive wheel as a cutting tool to remove material from a workpiece. It achieves fine finishes and accurate dimensions, particularly on hard materials. The process involves a rotating abrasive wheel that shaves off material to reach the desired shape and size, and is essential for creating flat, cylindrical, or conical surfaces in modern manufacturing.

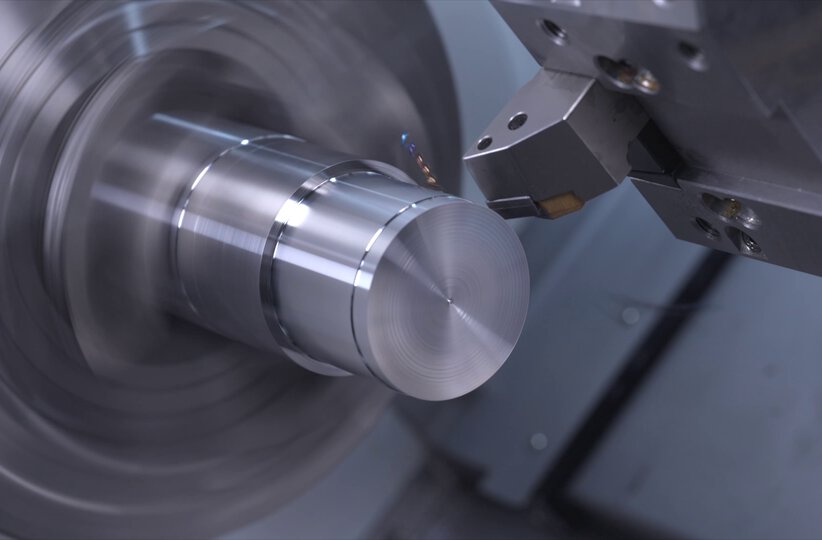

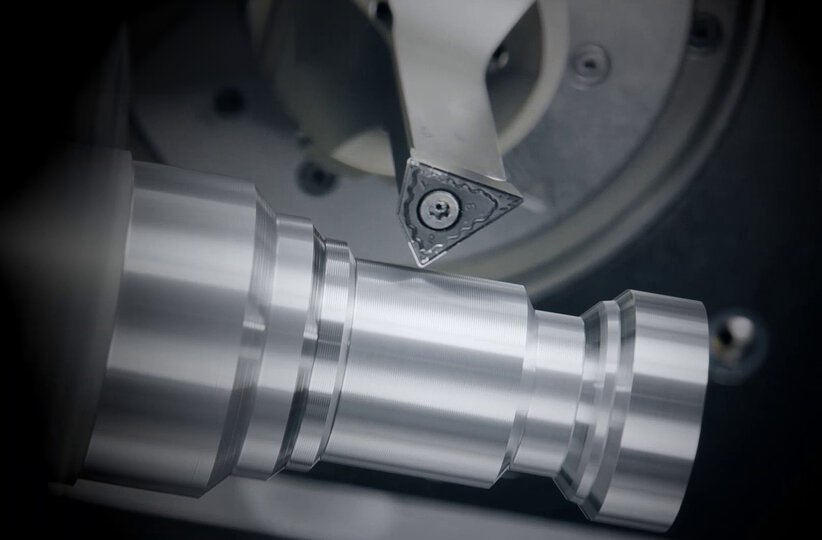

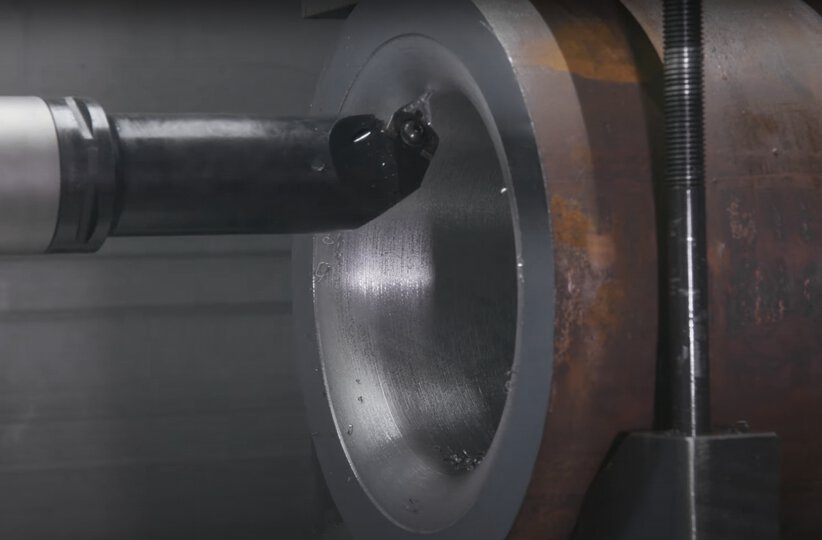

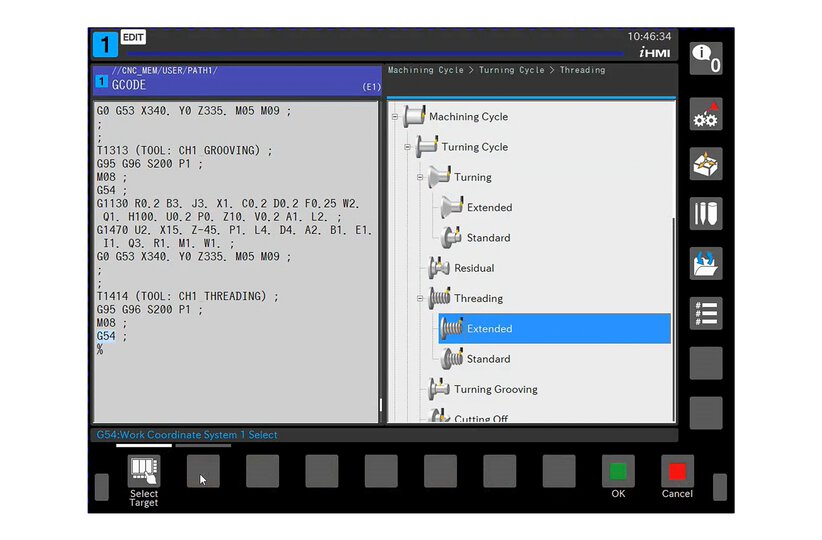

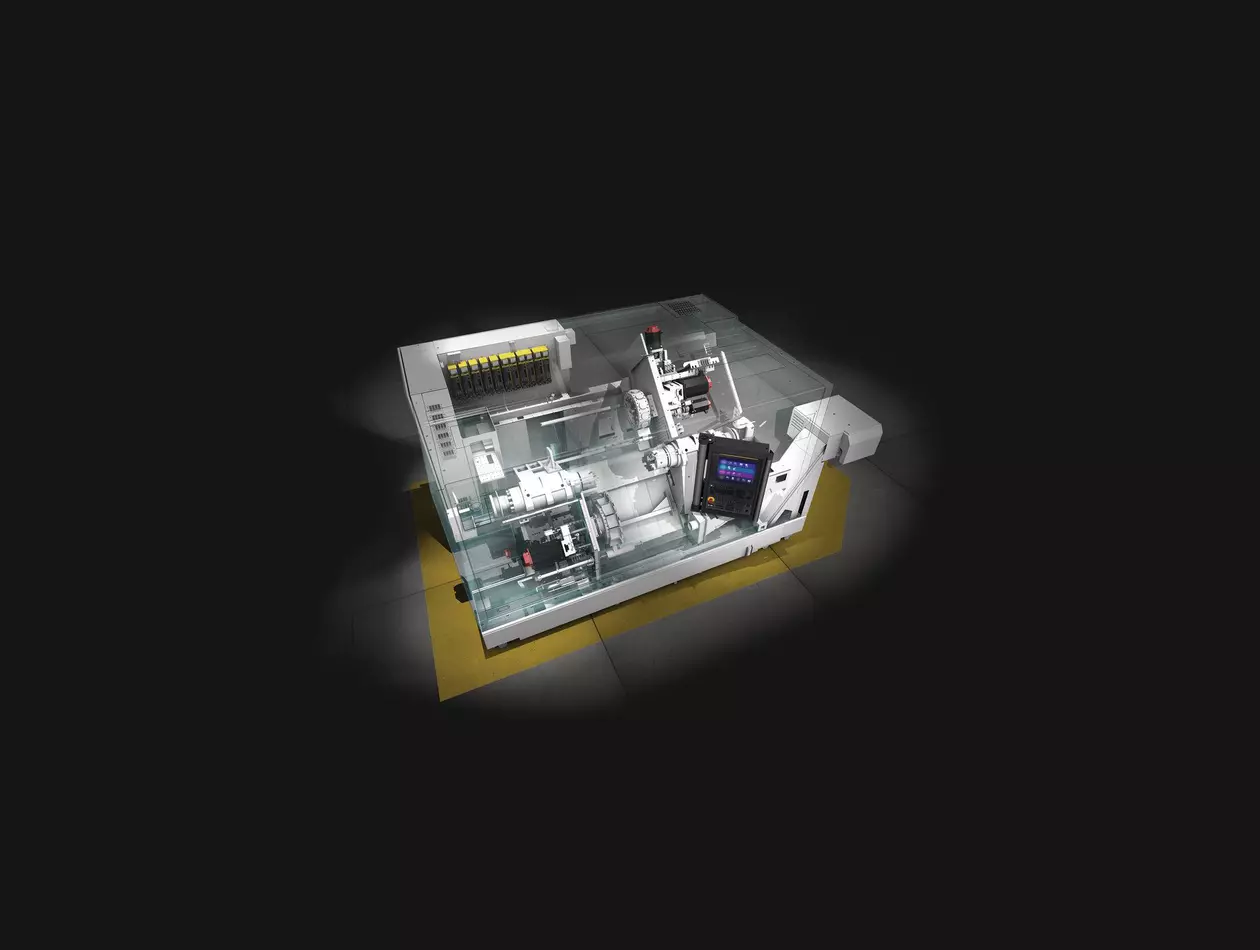

CNC Turning

CNC turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical shapes. It is ideal for producing parts with complex geometries and tight tolerances. In order to maximise your turning centre or lathe’s output, having a good CNC capable of managing and optimising a whole array of turning processes is essential. In addition to maximising productivity, a good CNC will also provide you with the flexibility to reduce turnaround times on small batches.

Wire Cutting EDM

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut intricate shapes and contours in hard metals and conductive materials. The wire generates a series of rapid electrical discharges, which erode the material with extreme accuracy without applying mechanical force. This non-contact method allows for the production of highly detailed, complex parts with excellent surface finishes, making it essential for industries that require precise machining, such as aerospace, medical, and mould-making.

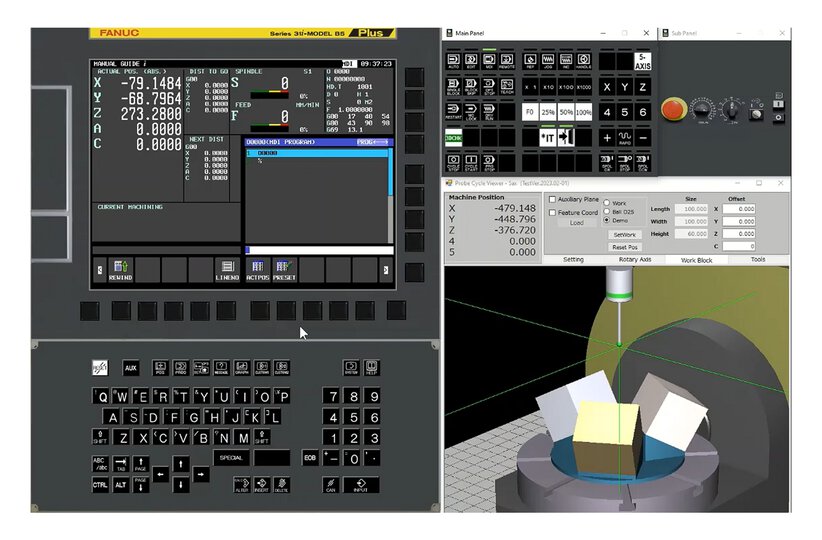

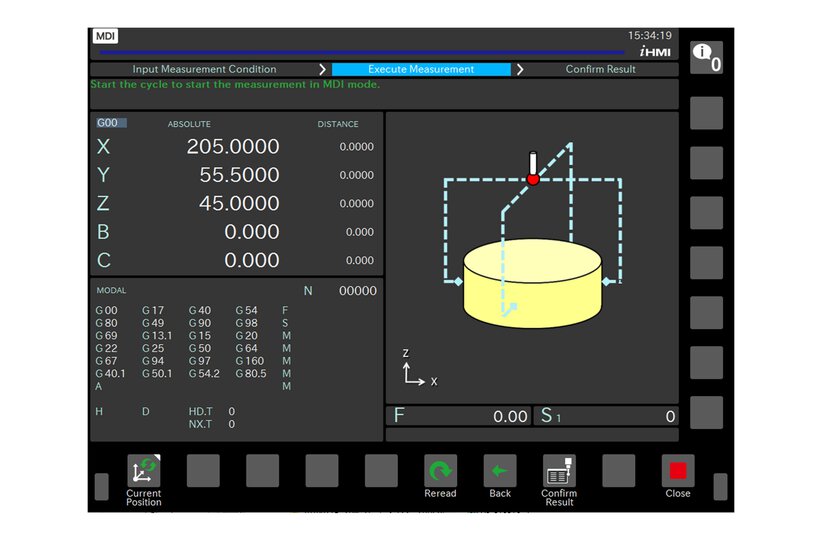

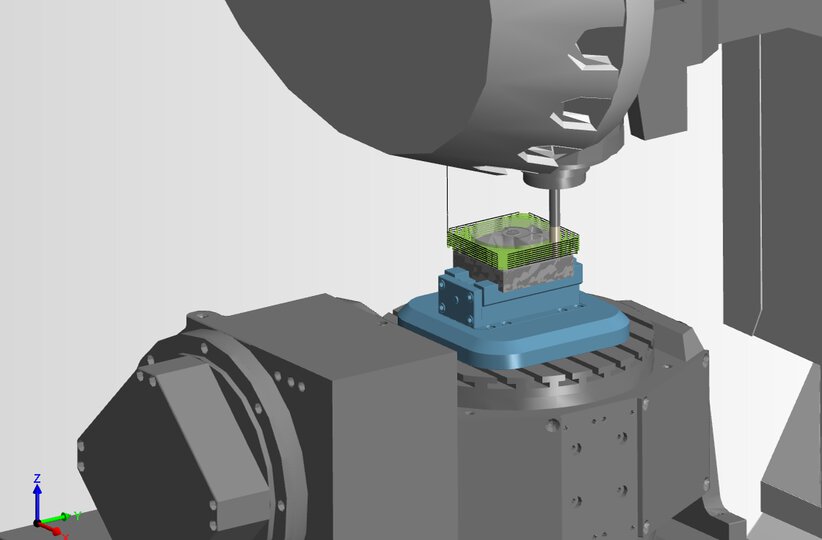

5 Axis Machining

5-axis CNC machining involves simultaneous movement along five axes—three linear (X, Y, Z) and two rotational. This capability allows for the creation of complex parts in a single setup, significantly enhancing precision and efficiency. By moving the cutting tool and workpiece along these five different axes, the 5-axis CNC can produce highly intricate shapes and detailed features.

Tailored Solutions for Your Industry

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!

Electric Vehicles

No one has more experience automating electric vehicle production than FANUC. Trust us to help automate all of your EV manufacturing processes.

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.