Improving Process Stability with IIoT Solutions

Detect deviations and take corrective actions promptly by monitoring your processes performance.

Increase Repeatability in Your Processes

In connected smart factories, monitoring and analysing operational and production data helps to identify variations in manufacturing, allowing you to take counteractions and create practices that increase repeatability. Instabilities can be automatically recognised, with fast delivery of notifications to stimulate responses.

Discover the different IIoT products in our portfolio that support production process stability.

FANUC IIoT Products to Support Process Stability

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

Monitoring

AI Servo Monitor

AI Servo Monitor is a software that visualises anomalies of drive systems for servos and spindles through machine learning. It can analyse daily processing data and display the results in intuitive...

Monitoring

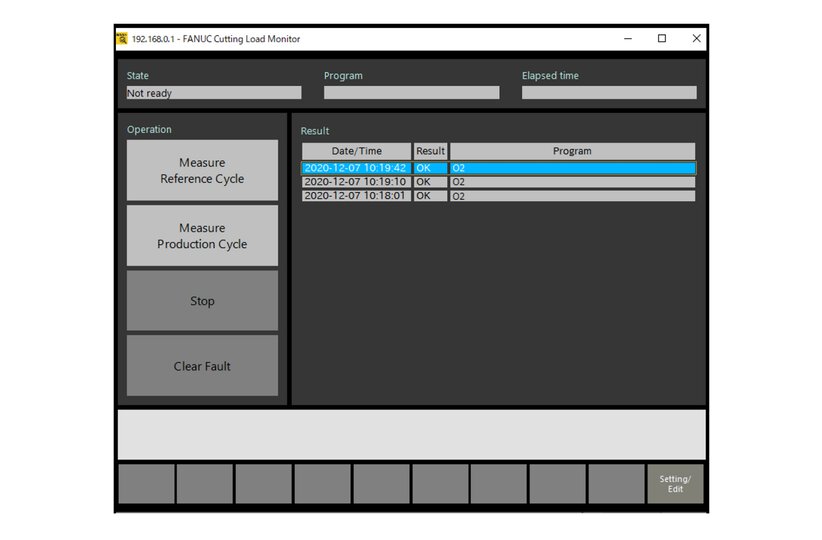

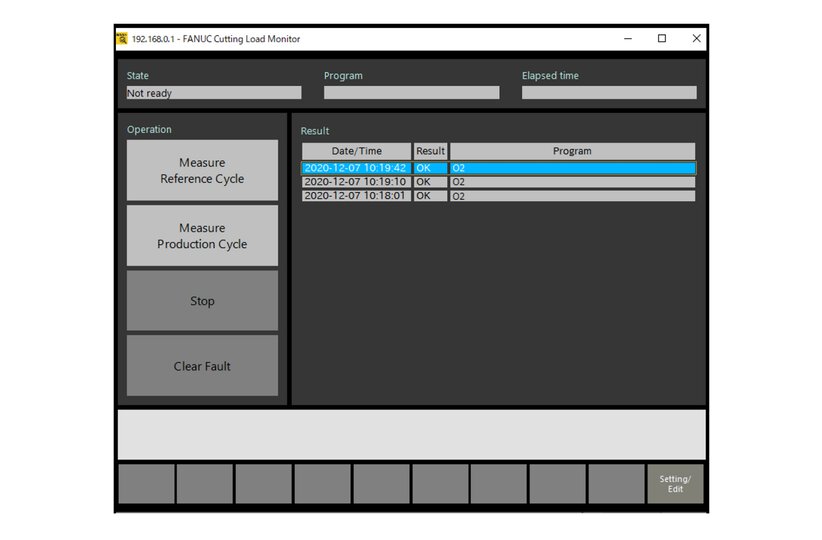

Cutting Load Monitor – PC and 𝑖HMI

Enhance the efficiency and precision of your CNC machining with our FANUC Cutting Load Monitor for PC and 𝑖HMI. This innovative solution offers real-time cutting load monitoring directly on your P...

IoT Solution

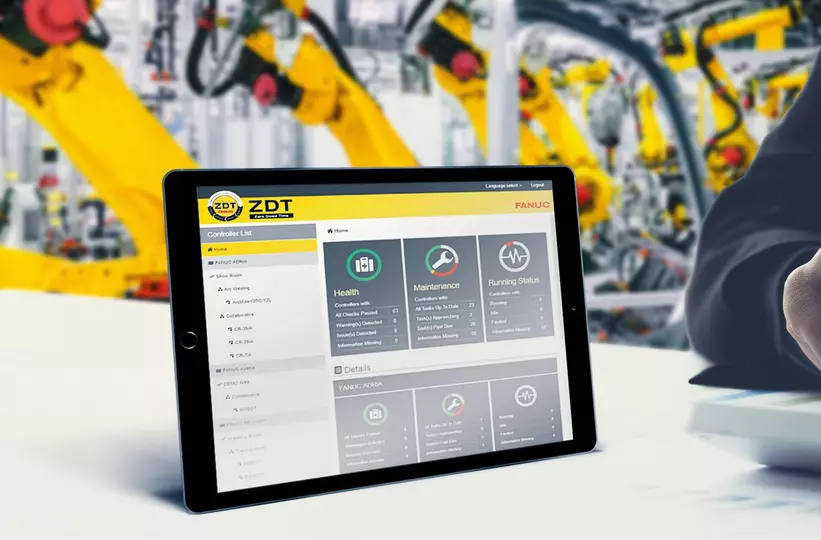

ZDT (Zero Down Time)

A robot breakdown can cause significant system production down time. FANUC Zero Down Time is an IoT solution designed to eliminate unforeseen production stoppage and enhance FANUC robot performance...

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

IoT Solution

FIELD system Basic Package

The FIELD system Basic Package is a platform designed to drive production improvements based on valuable production information, bridging the gap between data and productivity.

Start visualising a...

Monitoring

AI Servo Monitor

AI Servo Monitor is a software that visualises anomalies of drive systems for servos and spindles through machine learning. It can analyse daily processing data and display the results in intuitive...

Monitoring

Cutting Load Monitor – PC and 𝑖HMI

Enhance the efficiency and precision of your CNC machining with our FANUC Cutting Load Monitor for PC and 𝑖HMI. This innovative solution offers real-time cutting load monitoring directly on your P...

Monitoring

ROBOSHOT-LINK𝑖2

Remote management of your plastic production facility - ROBOSHOT-LINK𝑖2 is a quality information management tool that allows you to visualise ROBOSHOT data. Up to 1000 ROBOSHOT machines can be con...

Discover FANUC IIoT Solutions for Your Needs

Improving Manufacturing Performance with IIoT Solutions

Improving performance with IIoT solutions

Boosting Production Uptime with IIoT Solutions

Boosting production uptime with our advanced IIoT solutions

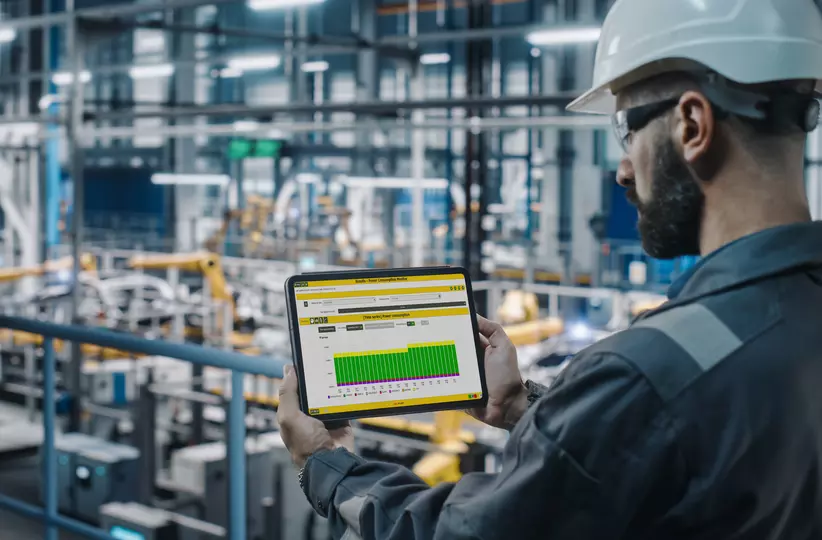

Optimise Energy Consumption with IIoT Solutions

Optimise energy consumption with IIoT Solutions

Improving Component Quality with IIoT Solutions

Improving component quality with IIoT solutions

Support Process Traceability with IIoT Solutions

Support process traceability with IIoT solutions