/

𝑖HMI Cycle Programming & MANUAL GUIDE 𝑖

𝑖HMI Cycle Programming & MANUAL GUIDE 𝑖

Share

Discover streamlined CNC programming with 𝑖HMI Cycle Programming and FANUC’s MANUAL GUIDE 𝑖. These powerful tools increase your productivity, simplify programming and streamline your shop floor.

- Key Benefits

- Key Features

- Documents

Key Benefits

Benefits for Your Business

Efficiency Unleashed

Experience unparalleled efficiency with FANUC CNC MANUAL GUIDE 𝑖 & 𝑖HMI Cycle Programming. Streamlines manufacturing, cuts setup time, and boosts

Unmatched Precision

With FANUC's precision control, your products will be consistently high-quality, with minimal rework and optimal efficiency.

User-friendly Interface

With FANUC's precision control, your products will be consistently high-quality, with minimal rework and optimal efficiency.

Customisable Programming

Tailor your operations and adapt to diverse manufacturing needs with FANUC's flexible cycle programming. Guarantee quick adjustments for any production scale.

Seamless Integration

Streamline your existing setup. Effortlessly integrate FANUC's CNC solutions with your current systems, enhancing productivity without disrupting existing workflows.

Key Features

Features Designed for Your Success

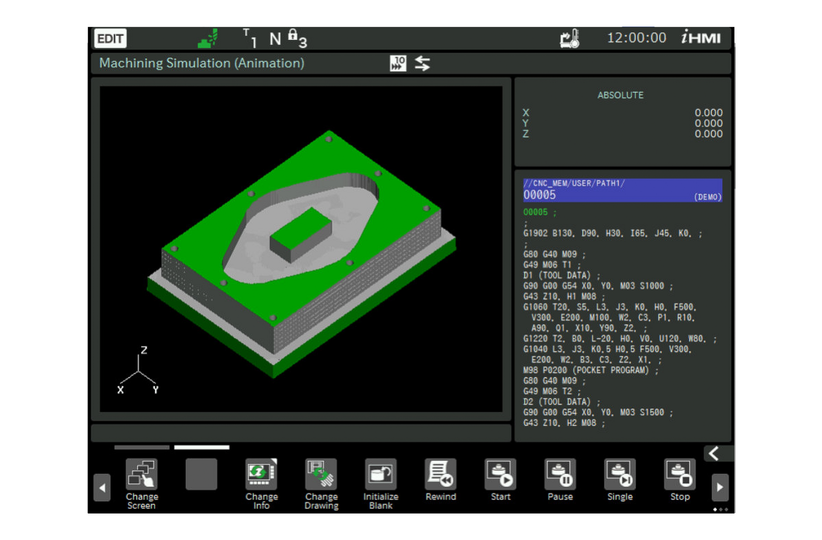

Shorten Your CNC Programming. Experience the ultimate in efficiency with our innovative software solution. Designed for faster setups and fewer errors, our intuitive interface and pre-defined cycles ensure you’re up and running in no time. Enhance your production quality with real-time path verification, effectively minimising programming mistakes and delivering unparalleled precision. Discover the future of seamless operations today.

𝑖HMI Cycle Programming

Ergonomic Design

ISO code-based format ensures consistency and ease of use.

Efficient Part Programme Creation

User-friendly menus and graphic simulations simplify complex tasks.

Seamless Environment Switching

Adapt to different machining modes effortlessly.

Precision Measurement Cycles

Built-in measurement cycles ensure accuracy.

MANUAL GUIDE 𝑖

Assisted and Conversational Programming

From basic tasks to intricate machining processes, MANUAL GUIDE 𝑖 guides you step by step.

Intuitive Graphical User Interface (GUI)

Create part programmes interactively with user-friendly icons.

Advanced Cycle Machining

Seamlessly handle turning and milling.

Efficient Tool Management

Streamline tool organisation effortlessly.

Background Machining Simulation

Visualise processes before execution.

Documents

Download for Additional Information

Access essential technical specifications and valuable information about our products through our downloadable documents, aiding your decision-making process and maximising the utilisation of your FANUC products.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT