Akim Metal - SMB

Constructorul de strunguri CNC preia controlul producției cu FANUC

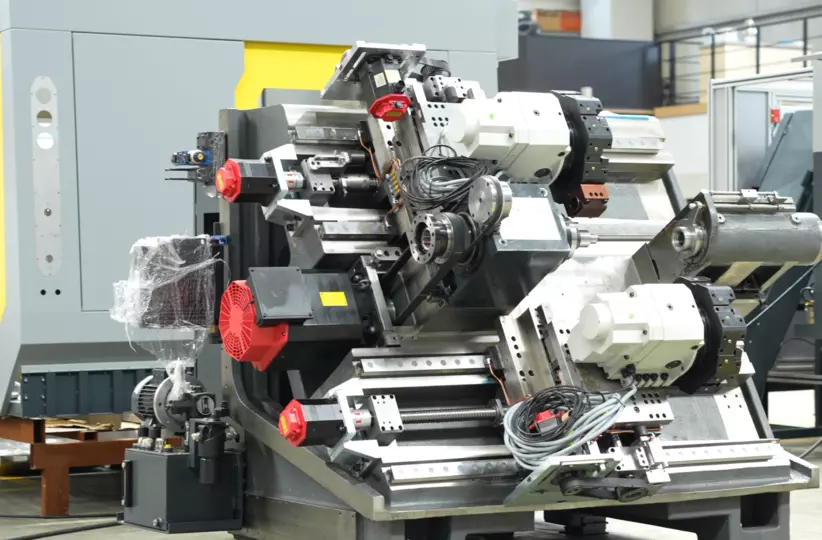

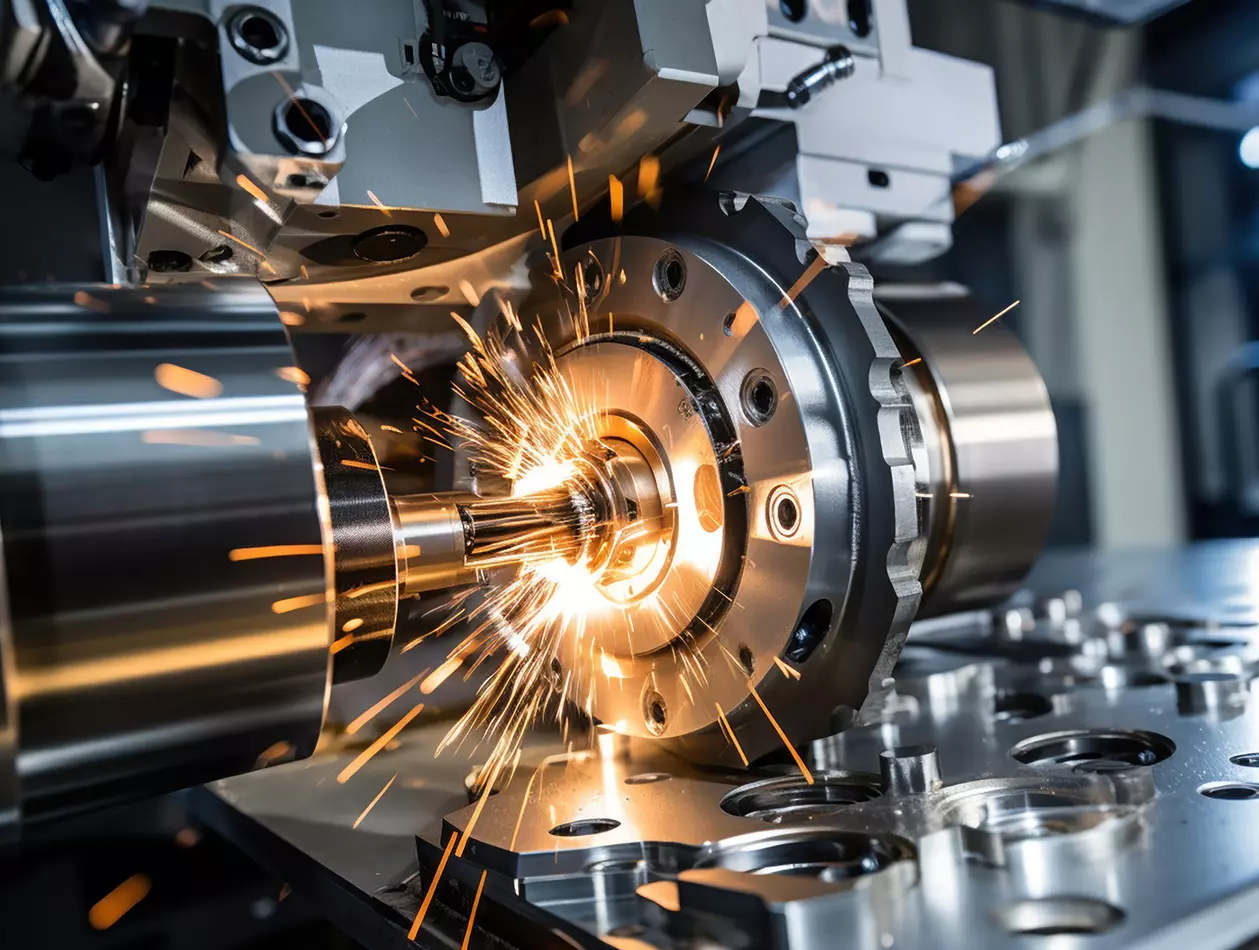

Într-o lume a componentelor inginerești din ce în ce mai complexe, mașinile-unelte au nevoie de tot mai multe capacități și funcții. Simplul strung, un pilon de bază al industriei de prelucrare, este un exemplu în acest sens. Marca SMB a companiei Akim Metal, cu sediul în Turcia, construiește astăzi strunguri cu turele duble cu servo-control, lunetă programabilă, scule live, contraputere programabilă și automatizare integrată. Pentru a asigura un control optim al procesului în căutarea unei calități, a unei repetabilități și a unei productivități din ce în ce mai ridicate a componentelor, compania utilizează sistemele CNC FANUC.

Share

Sistemele CNC FANUC permit o gamă largă de funcții de strunjire pe strungurile SMB

Arborele excentric nu reprezintă o problemă pentru FANUC 0𝑖-TF Plus CNC

Funcția Dual-path gestionează independent turelele duble

Suport cuprinzător din partea echipei locale de service și ingineri FANUC

Get Inspired

Studii de caz FANUC

Explorați gama noastră cuprinzătoare de soluții de automatizare a fabricilor, prezentate în studii de caz detaliate și concepute pentru a optimiza și raționaliza orice proces de producție.

Strunjire CNC

Strunjirea CNC este un proces de prelucrare în care o unealtă de tăiere îndepărtează materialul de pe o piesă de prelucrat rotativă pentru a crea forme cilindrice precise. Este ideal pentru producerea de piese cu geometrii complexe și toleranțe strânse. Pentru a maximiza producția centrului de strunjire sau a strungului dumneavoastră, este esențial să aveți un CNC bun, capabil să gestioneze și să optimizeze o serie întreagă de procese de strunjire. În plus față de maximizarea productivității, un CNC bun vă va oferi, de asemenea, flexibilitatea de a reduce timpii de producție pentru loturile mici.

Toate industriile

Explorați gama noastră cuprinzătoare de soluții de automatizare a fabricilor, concepute pentru a optimiza și eficientiza orice proces de producție.