Etasis

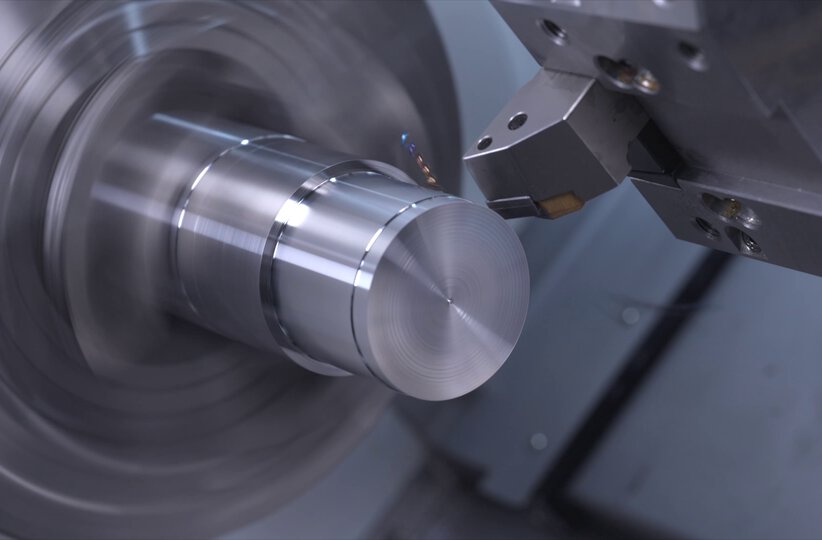

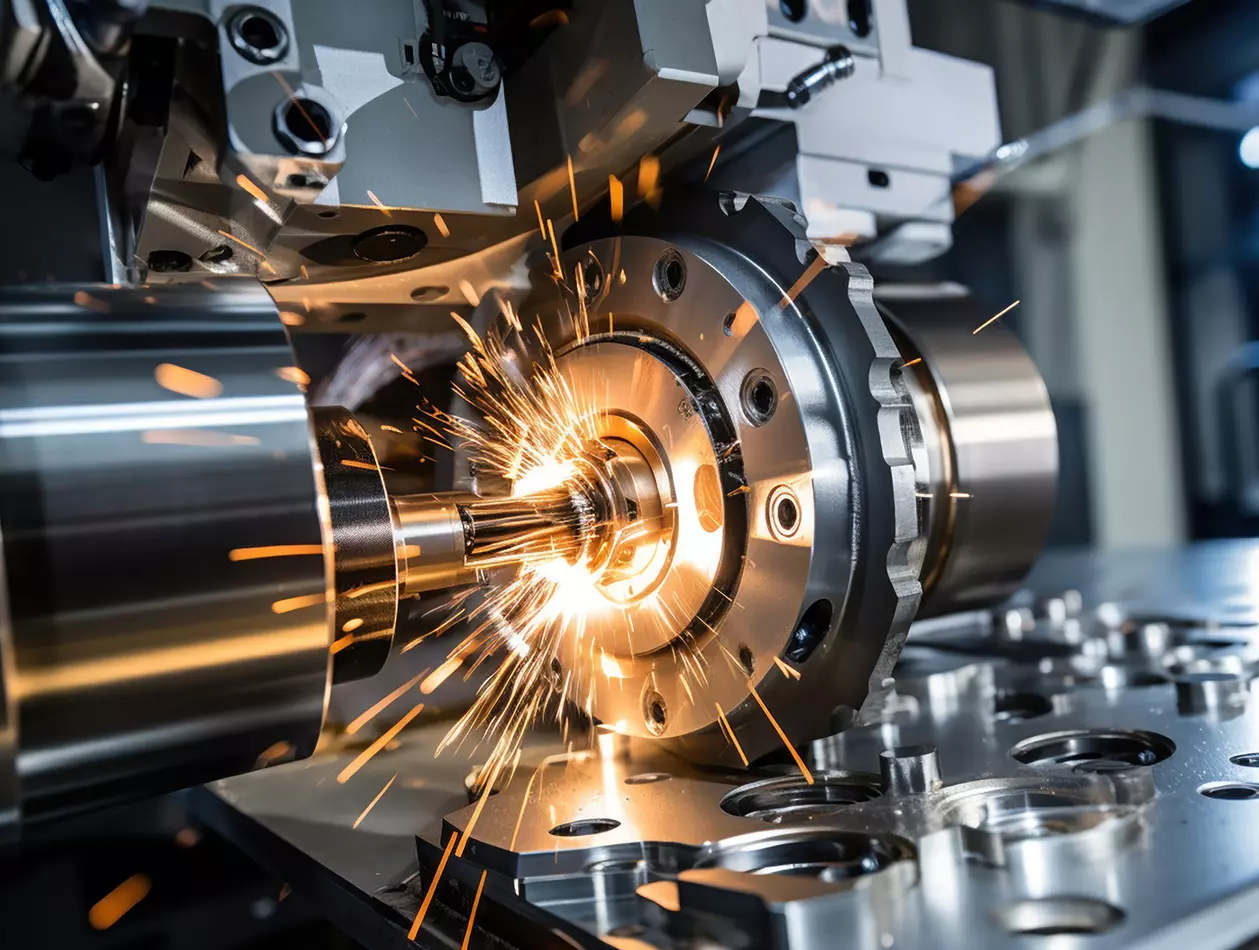

Break Up Long Chips with FANUC Servo Learning Oscillation Function

Long chips from machining operations disrupt machine function. ETASIS, a Turkish tool producer, sought a solution. FANUC’s CNC offers the Servo Learning Oscillation Function, which oscillates the tool along the cutting direction, maintaining quality and reducing cleanup. This solution is essential for robotic machine tending and eliminates the need for chip-breaking equipment. ETASIS is highly satisfied with the results.

Share

The FANUC Servo Learning Oscillation function increases the production quality of the machines.

High benefits in terms of cost and time.

Fast and solution-oriented service from FANUC.

Technical support in different countries.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

CNC Milling

CNC milling is a machining process that uses computer-controlled rotating cutting tools to remove material from a workpiece to create a desired shape. It is widely used for producing precision parts with complex geometries. The process involves securing the workpiece on a movable table and using various tools to cut, drill, and shape the material based on programmed instructions.

CNC Turning

CNC turning is a machining process where a cutting tool removes material from a rotating workpiece to create precise cylindrical shapes. It is ideal for producing parts with complex geometries and tight tolerances. In order to maximise your turning centre or lathe’s output, having a good CNC capable of managing and optimising a whole array of turning processes is essential. In addition to maximising productivity, a good CNC will also provide you with the flexibility to reduce turnaround times on small batches.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.