NTM

Heavy Lifting for Truck Construction

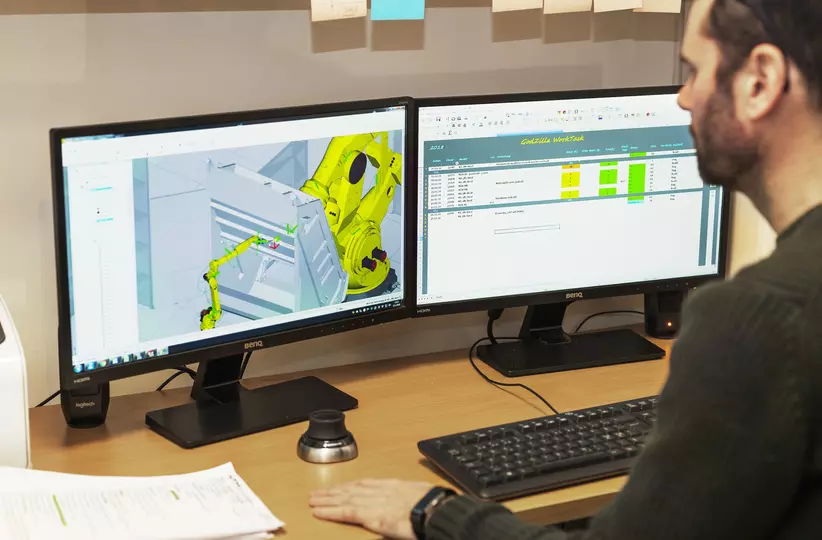

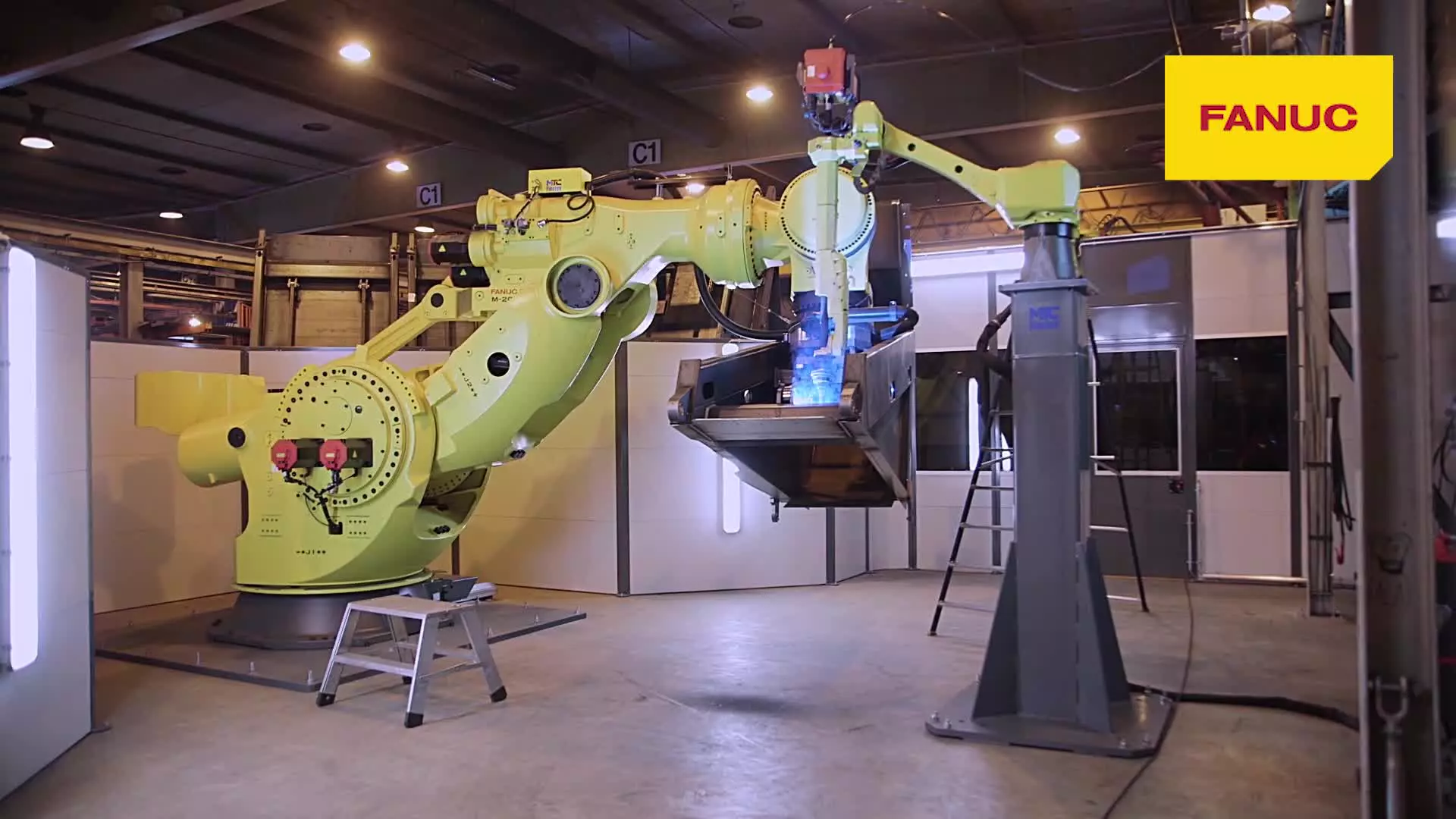

NTM was able to increase the production capacity for its refuse collection vehicles by opting to automate the night shift. By using a heavy-duty robot that can lift up to two tonnes and a robotic welding solution, the company's Finnish plant can now work unmanned at night or on weekends.

Share

Robot handling payloads of up to two tonnes.

Strong and versatile robot solution.

Functions perfectly in an automated system with several robots.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Material Handling

Automise material handling with industrial robots to unlock numerous advantages for your business. Significantly enhance efficiency and productivity by reducing the time and effort required for manual handling. Let robots operate continuously without fatigue to ensure consistent performance and minimise errors, leading to higher throughput and faster processing times.

Arc Welding

Automate your arc welding process with industrial robots to enhance precision and consistency, ensuring high-quality welds. Boost your productivity by operating continuously without fatigue and reducing production time. Improve safety by minimising human exposure to hazardous fumes and extreme heat. Additionally, achieve cost efficiency by reducing labour costs and requiring less rework.

Robotics & Automation for the Automotive Industry

Automotive excellence: FANUC's versatile automation solutions.