/

𝑖RVision

𝑖RVision

Share

We empower FANUC robots to see!

𝑖RVision is FANUC’s unique, fully-integrated visual detection system that enables FANUC robots to see - making production faster, smarter and more reliable. Based on over 30 years of experience, FANUC's team of in-house experts are dedicated to developing integrated robotic vision products that are quick to install, easy to use and ultra-flexible. And best of all, the 𝑖RVision application solution can be implemented without complicated programming or expert knowledge. Setting up 𝑖RVision is effortless, as it guides you through each step of the process. A powerful vision toolbox is integrated in the standard 𝑖RVision package to support any custom-made application.

- Insights

- Key Benefits

- Key Features

- Functions

- Documents

Insights

Experience the Fastest, Easiest, most Reliable Robotic Vision System

• Up to 27 cameras (B/W and colour) in different resolutions connectable

• Supported vision technologies: 2D, 2½D, 3D

• Wide range of applications include palletising, inspection, bin picking and visual line tracking

• Wide portfolio to cover different measurement sizes and distances

• Detection of non-moving and moving parts independent of their size, shape or position

• Compatible with other FANUC tools such as Bin Picking, 𝑖RPickTool and 𝑖RCalibration

• Automatic calibration process is available for high accuracy and ease of use.

Key Benefits

Benefits for Your Business

Easy Plug and Play Technology

Plug and Play 𝑖RVision as it is fully robot integrated, not requiring an interface to external devices or any additional hardware for the set up and operation. Configure the vision process directly on the teach pendant of the robot controller or on an external PC by using a web browser.

Efficient Ease of Use

Let yourself be guided through each step along the way. The solution is setup within a fast matter of time. A powerful vision toolbox, that is integrated in the standard 𝑖RVision package, supports any tailor-made application.

Easy Simulation

Simulate the process beforehand in ROBOGUIDE, allowing you to select and modify parts and dimensions as required and evaluate the feasibility and efficiency of the entire process before making a purchase decision.

Key Features

Ultimate Flexibility for your Production Processes

Perform Visual Image Processing

Perform Picking and Placing of Randomly Positioned and Oriented Parts

Sort by Colour, Shape or many other Features

Read 1D and 2D barcodes

Control Completeness and Dimensions

Perform Quality Controls

Functions

Cover all Types of Vision with 𝑖RVision

𝑖RVision 2D

Find parts and their precise position and orientation (X,Y and R). Increase the production flexibility thanks to the eliminated need for expensive positioning fixtures. 2D vision is suited for any material handling applications including palletising and pick and place applications, as well as for vision inspections.

𝑖RVision 3D

Acquire a detailed depth image by a quick projection & snap of a single blue pattern. 3DV sensors can be used for bin picking, tote picking, kitting, depalletising, presence/absence check, 3D visual line tracking and many other applications. 3DV sensors are also ideal for 2D applications where objects are hard to find due to low contrast or noisy 2D image data. All 3DV sensors support both robot-mount and fixed installation.

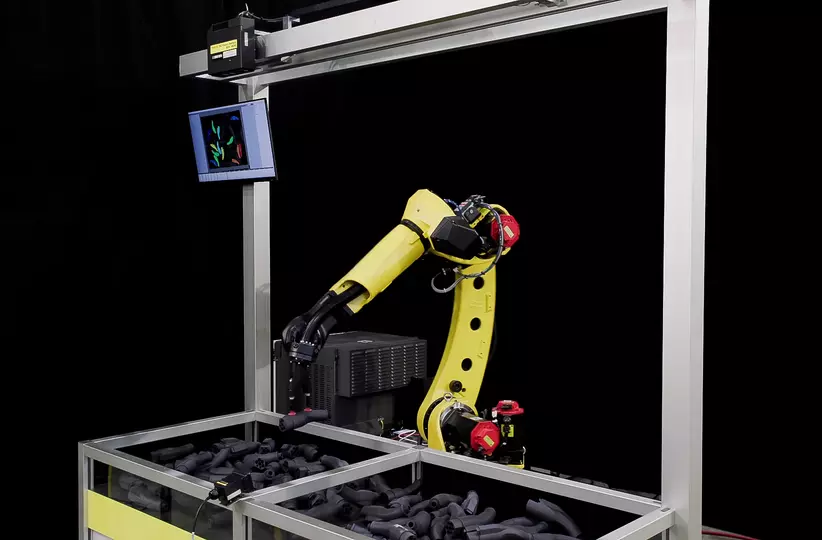

𝑖RVision Bin Picking

The 𝑖RVision Bin Picking option provides you important and useful functions that are necessary in addition to vision functionality such as collision avoidance with the bin or objects for a successful bin picking or tote picking application. All types of 𝑖RVision sensors are supported.

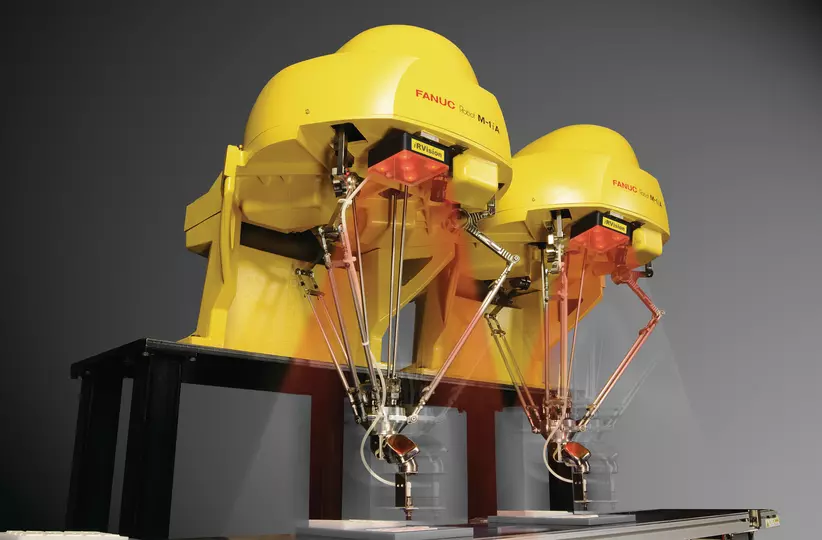

𝑖RPickTool

𝑖RVision functionality can be added to 𝑖RPickTool to support the detection of randomly placed parts on a moving conveyor. This way, the 𝑖RPickTool equips single or multiple robots with the ability to identify, pick and place items in linear and/or circular conveyor tracking. This is supported by a wide range of features including advanced queue management, buffering and tray functionality.

𝑖RCalibration

Designed to enhance the precision and performance 𝑖RCalibration functions are based on 𝑖RVision. It is a stand-alone service tool to simplify the initial setup and speed up the entire integration, which improves application accuracy.

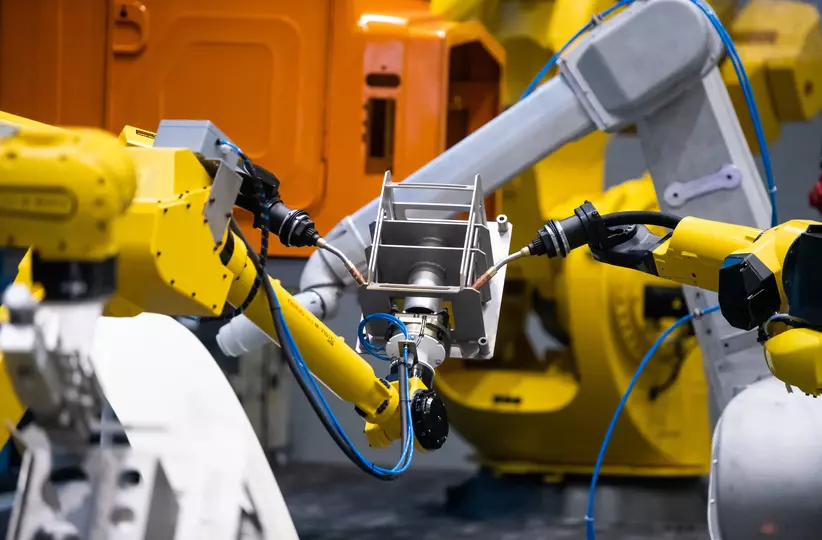

𝑖RVision Weld Tip Inspection

𝑖RVision Weld Tip Inspection for spot welding supports the optical wear and condition control of a WeldTip during automatic production. Based on the result, the tip can be reworked or replaced without a production interrupt.

𝑖RTorchMate

𝑖RTorchMate supports the optical control of an e.g. ArcTorch during automatic production. Based on the result ArcTorch offset can be added or other actions can be executed.

Documents

Download Additional Information

Access essential technical specifications and valuable information about our products through our downloadable documents, aiding your decision-making process and maximising the utilisation of your FANUC products.

Get in Touch

Solutions

CUSTOMER SERVICE

NEWS & MEDIA

CONTACT