FANUC Cobot Helps GER4TECH Make its Move

Inspírese

El fabricante de campanas aprovecha las ventajas de los robots FANUC

La cooperación entre FANUC y el fabricante de campanas extractoras Silverline, que comenzó con un proyecto especial de unión automatizada en 2015, ha dado lugar a un total de 17 robots trabajando en toda la fábrica de la empresa en Turquía. FANUC es testigo habitual de este tipo de resultados, en los que dar el salto inicial a la inversión en robótica lleva a una comprensión casi inmediata de que la fabricación puede alcanzar niveles de Rendimiento totalmente nuevos.

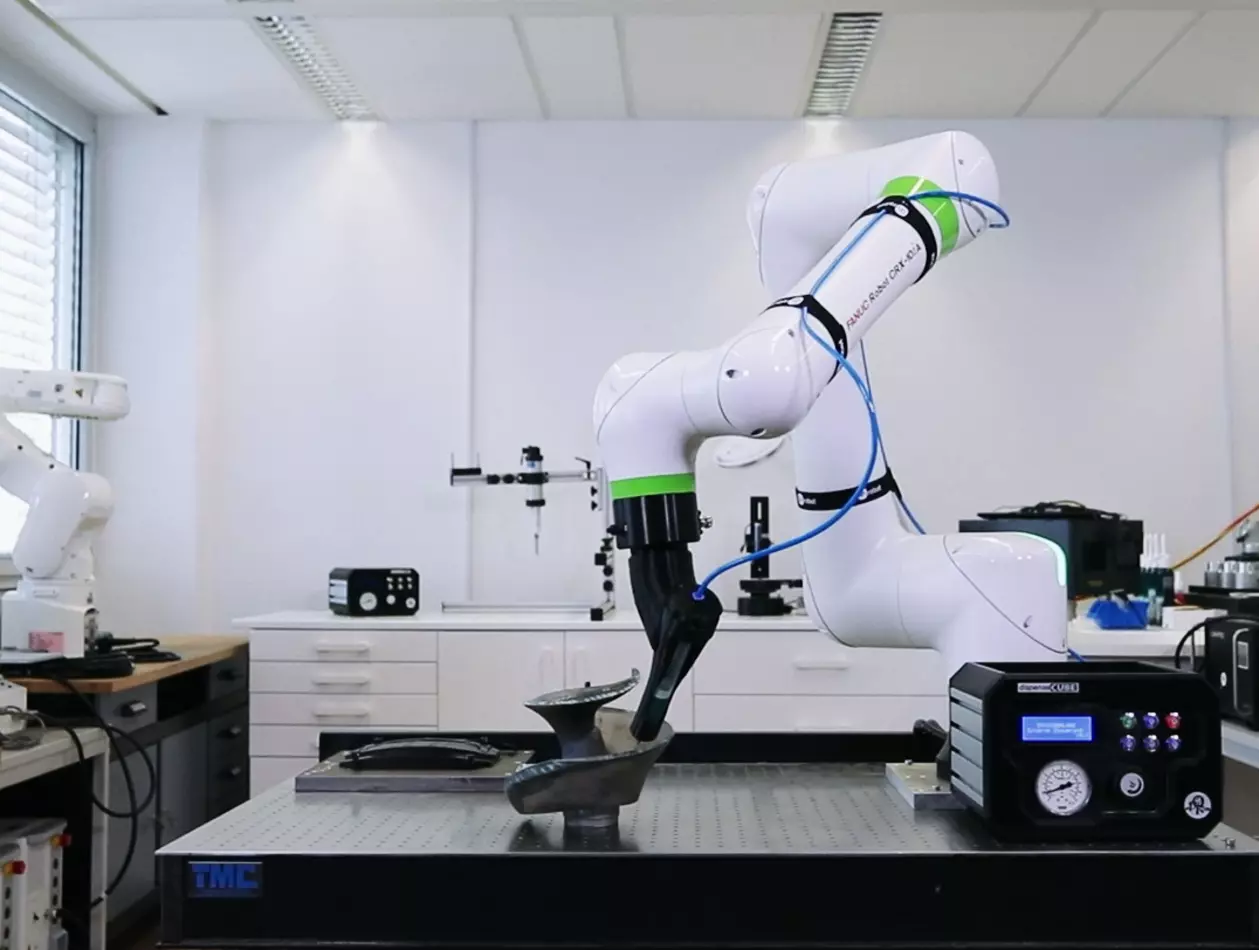

Uniendo fuerzas: El cobot de FANUC es la solución óptima para los adhesivos de AS

La automatización no es sólo para aplicaciones de gran volumen. AS Adhesive Solutions, consultora especializada y socio de la industria de adhesivos, reconoce que muchas PYMES que procesan pequeñas cantidades pueden beneficiarse de procesos total o parcialmente automatizados. En estos casos, un robot colaborativo (cobot) suele ser la mejor solución.

Casos prácticos de FANUC

Explore nuestra completa gama de soluciones de automatización, expuestas en detallados estudios de casos y diseñadas para optimizar y agilizar cualquier proceso de fabricación.

Alimentación de máquinas