𝑖RVision

- Vpogledi

- Ključne prednosti

- Ključne lastnosti

- Funkcije

- Dokumenti

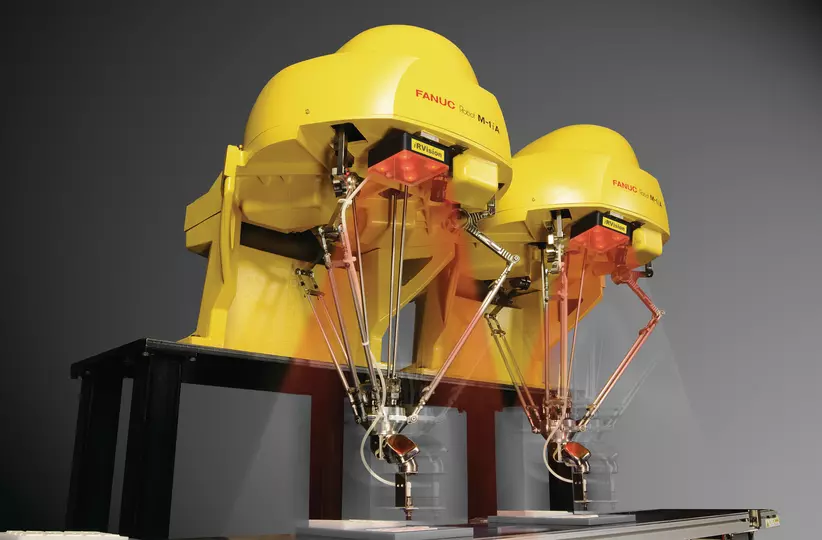

Spoznajte najhitrejši, najlažji in najzanesljivejši sistem robotskega vida

- Priključiti je mogoče do 27 kamer (črno-belih in barvnih) različnih ločljivosti

- Podprte tehnologije vida: 2D, 2½D, 3D

- Širok nabor aplikacij vključuje paletiranje, pregledovanje, pobiranje v koš in vizualno sledenje linijam

- Širok nabor za pokrivanje različnih merilnih velikosti in razdalj

- Zaznavanje negibljivih in gibljivih delov ne glede na njihovo velikost, obliko ali položaj

- Združljivo z drugimi orodji FANUC, kot so Bin Picking, 𝑖RPickTool in 𝑖RCalibration

- Za visoko natančnost in preprosto uporabo je na voljo samodejni postopek kalibracije.

Prednosti za vaše podjetje

Enostavna tehnologija Plug and Play

Učinkovita enostavnost uporabe

Enostavna simulacija

Največja prilagodljivost za vaše proizvodne procese

Delovanje vizualne obdelave slik

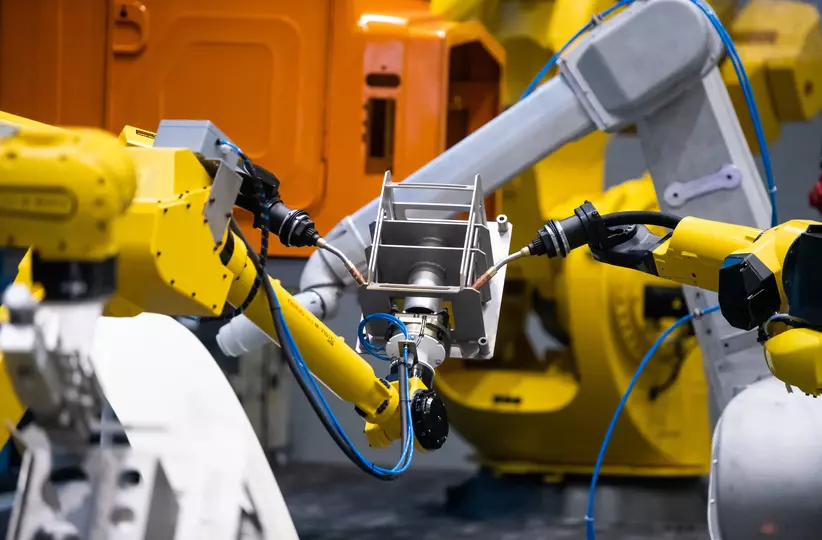

Izvajajte izbiranje in nameščanje naključno postavljenih in orientiranih delov

Razvrsti po barvi, obliki ali številnih drugih funkcijah

Branje črtnih kod 1D in 2D

Popolnost nadzora in dimenzije

Delovanje nadzora kakovosti

Pokrijte vse vrste vida z 𝑖RVision

𝑖RVision 2D

𝑖RVision 3D

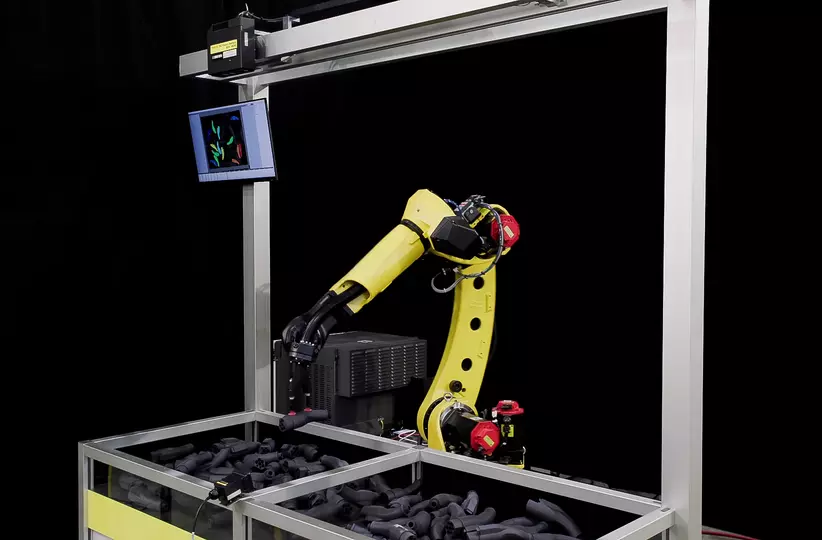

𝑖RVision Bin Picking

𝑖RPickTool

𝑖RCalibration

𝑖Pregled zvarjenih konic RVision

𝑖RTorchMate

Prenesite dodatne informacije

V naših dokumentih za prenos lahko dostopate do bistvenih tehničnih specifikacij in dragocenih informacij o naših izdelkih, kar vam bo pomagalo pri sprejemanju odločitev in povečalo izkoriščenost izdelkov FANUC.