Vernay

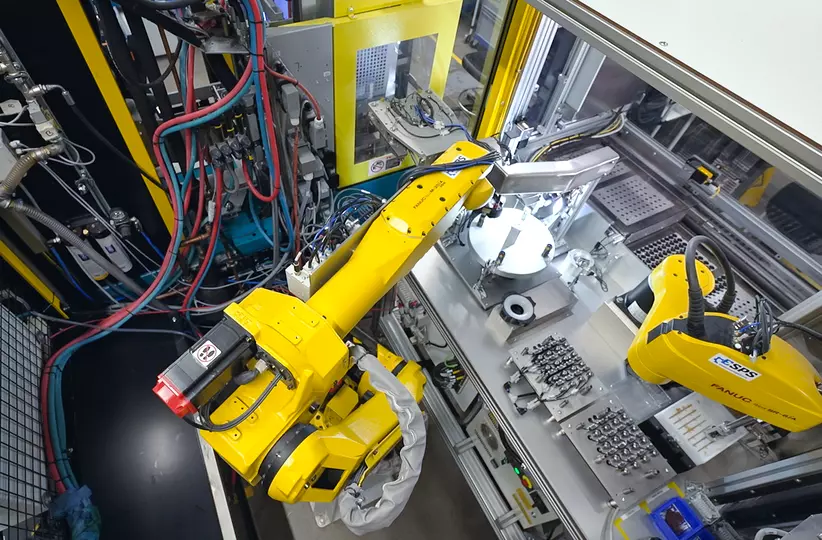

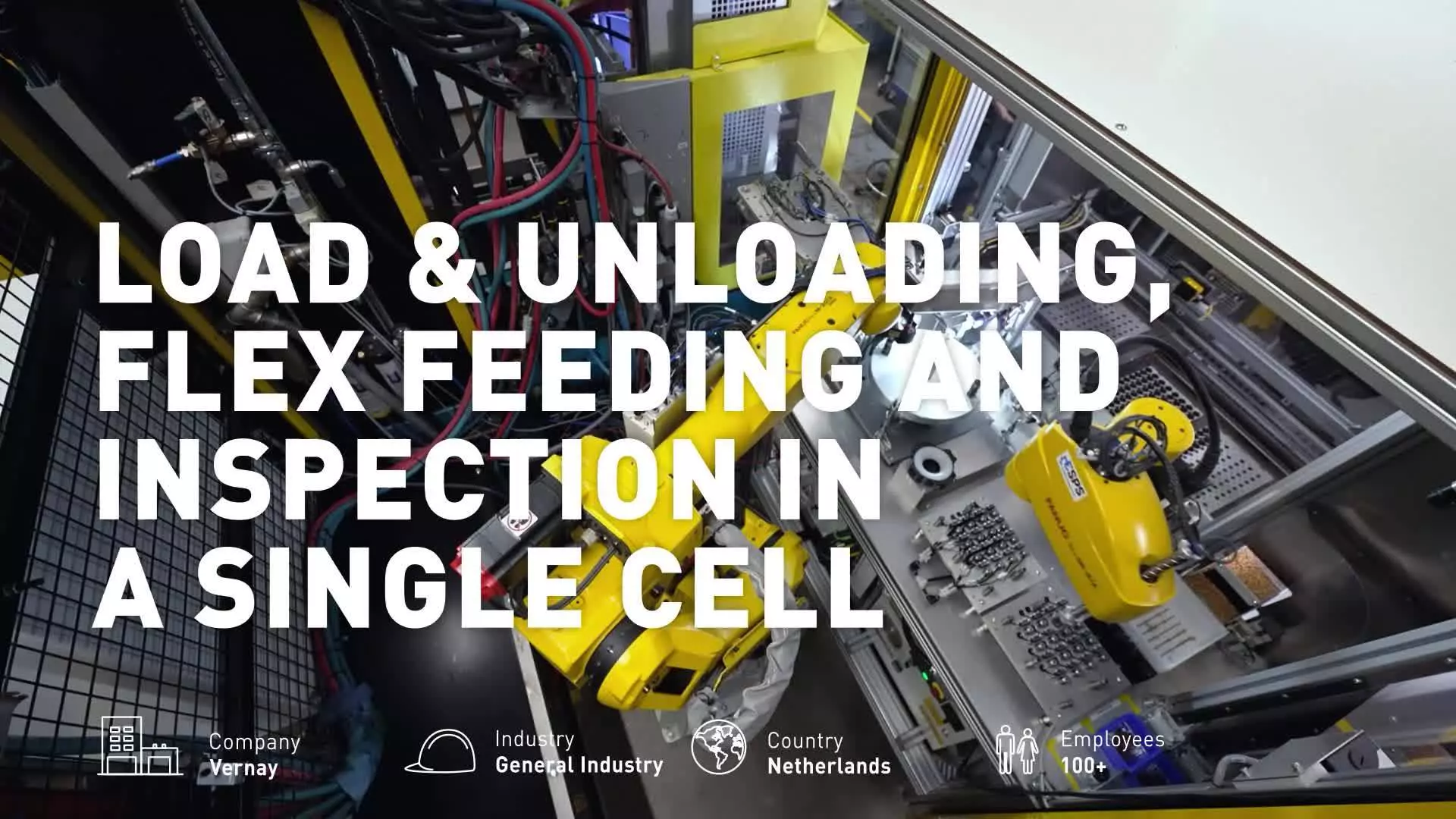

Loading & Unloading, Flex Feeding, and Inspection in a Single Cell

Vernay is globally renowned for flow control solutions, producing over a billion rubber valve components annually across Asia, the Americas, and Europe. Their critical products, used in devices like respirators and EV battery systems, must meet the highest quality standards with zero defects.

Partilhar

Parts are produced 24 hours a day without interruptions.

Global availability of FANUC products and parts.

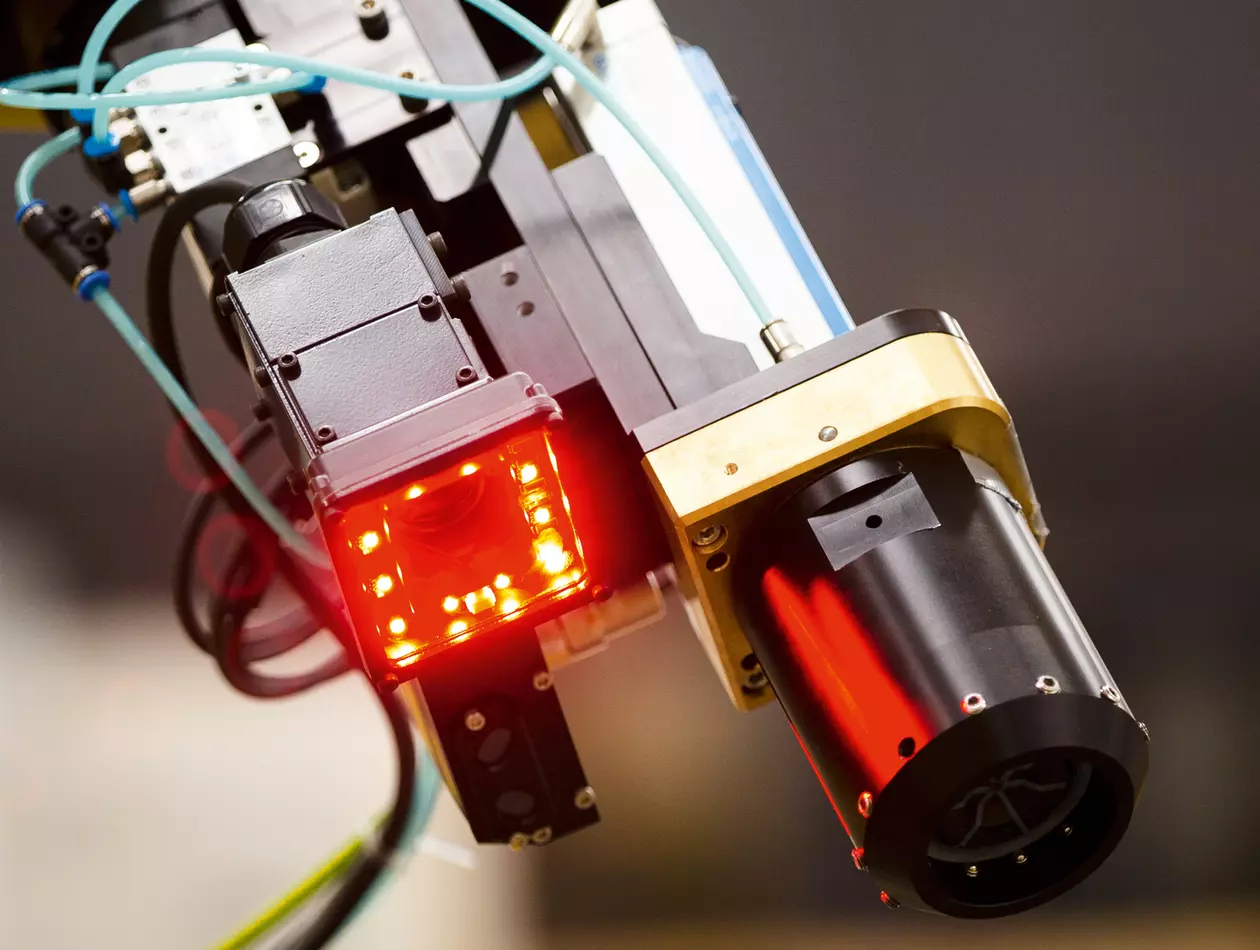

Quality control inspection with the SCARA robot.

Get Inspired

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Carga e Descarga de máquinas

Automatize a carga/descarga de máquinas com robôs para melhorar significativamente a sua produção, proporcionando uma precisão superior e um funcionamento contínuo, ao contrário do controlo manual. Aumente a eficiência, obtenha uma produção consistente, reduza os custos de mão de obra e acrescente um valor substancial a todo o seu processo de produção.

Sistemas de Inspeção Visual

A tecnologia de inspeção visual melhora os seus processos de fabrico com sistemas automatizados baseados em imagem que inspeccionam e analisam objectos com precisão. As soluções avançadas de inspeção visual utilizam câmaras, sensores e software de ponta para captar e processar imagens, detetar defeitos, medir dimensões e garantir que os seus produtos cumprem os mais elevados padrões de qualidade.

Manipulação de materiais

Automatize a manipulação de materiais com robôs industriais para obter inúmeras vantagens para a sua empresa. Aumente significativamente a eficiência e a produtividade, reduzindo o tempo e o esforço necessários para o manuseamento manual. Permita que os robôs funcionem continuamente sem fadiga para garantir um desempenho consistente e minimizar os erros, conduzindo a um maior rendimento e a tempos de processamento mais rápidos.

All Industries

Explore our comprehensive range of factory automation solutions, designed to optimise and streamline any manufacturing process.