‘Breakthrough’ automated broccoli harvester turns to FANUC for a helping hand

FANUC robots have been integrated into a ‘breakthrough’ selective automated broccoli harvesting system, which has the potential to revolutionise the UK vegetable industry in the face of spiralling production costs.

Over 75,000 tonnes of broccoli are grown and harvested across the UK each year. Commercial growers typically rely on a team of seven people to manually harvest crops. The monotonous work often takes place in unpleasant working conditions and can lead to repetitive strain injuries and other long-term health conditions.

Labour is a significant cost for UK growers, and changes to the National Living Wage are set to see manual harvesting costs increase by 35% by 2021, thus threatening the competitiveness of UK growers and potentially driving production to low-cost countries overseas.

To help future-proof production for UK broccoli growers, agricultural R&D specialists KMS Projects conceived the idea to create a selective automated harvester that could reduce the need for manual harvesting, subsequently reducing production costs and improving harvesting speeds.

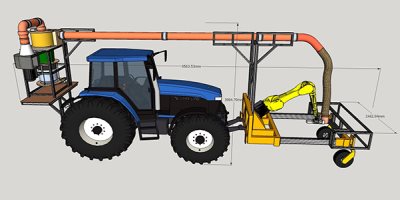

The automated harvester sees three FANUC 6-axis M-20iB robots mounted onto a rig, powered and driven by a tractor. Each robot arm is fitted with a cutting tool, and can harvest a head of broccoli every three seconds – twice as fast as a manual picker. The hollow wrist and body of the M20iB robots not only keep weight to a minimum, but are also rated to IP67, to guarantee reliable operation outside and protect against dust, soil and water ingress. State-of-the-art servo technology and 6-axis range of movement also help to facilitate fast, intricate operation within the harvester’s confined rig area.

A built-in visual detection system works in conjunction with the FANUC robots to ensure only those broccoli heads which meet pre-determined size requirements are harvested. As well as being faster than manual harvesting, thanks to its intelligent vision system the automated rig is able to work effectively throughout the night to further boost productivity.

Realtime data analysis can be monitored both from a HMI in the tractor cabin, and remotely from a central office.

While the system is currently tailored to broccoli harvesting, it has the potential to be adapted to automate the harvesting of other brassica and leaf crops such as cabbage and lettuce, both in the UK and beyond.

While the system is currently tailored to broccoli harvesting, it has the potential to be adapted to automate the harvesting of other brassica and leaf crops such as cabbage and lettuce, both in the UK and beyond.

Peter Keeling at KMS Projects, adds: “While the UK’s agricultural industry is an integral element of our national supply chain, growers are facing spiralling production and harvesting costs which have the potential to cripple the industry, and drive production overseas. Having grown cauliflower myself, I know all too well the monotonous and labour intensive task of manually harvesting vegetables. We have spent the last ten years developing what we believe to be the first automated selective harvesting rig. FANUC has been a central partner for many years, from the initial testing and simulation stages using simple cardboard boxes, right the way through to the design of our single-module pre-production rig in time for the UK’s 2018 broccoli season. We will conduct further field trials this year, and use the empirical data to fine tune the performance, with a view to building a small number of three-headed rigs in time for commercial use in the 2019 season. In short, this has the potential to help growers drive growth and become more profitable.”

Oliver Selby, Technical Sales Support Engineer at FANUC UK, comments: “The benefits of industrial automation are far-reaching and it is fantastic to see KMS Projects using FANUC robots to make a tangible difference to home-grown vegetable production. Broccoli picking is just one great example for the use of robotics in agriculture. In time, we will see more and more applications develop as the industry accepts and adopts the need for automation in order to stay competitive. There is no escaping from the fact that UK growers are facing significant cost increases over the coming years, however innovations such as this can go a long way to offsetting the potential negative impact and help future proof the industry for years to come.”

For more information on KMS Projects’ automated broccoli harvester, please visit: https://www.kmsprojects.co.uk/.

For more information on FANUC’s range of industrial robots, please visit: www.fanuc.eu/robots.

ENDS

For all media enquiries, please contact:

Andy Williams at WPR Agency

Tel: +44 (0) 121 456 3004

E-mail:

andy@wpragency.co.uk

FANUC UK

At its state-of-the-art headquarters in Ansty Park, Coventry, FANUC UK brings together world-leading capabilities in industrial robots, machine tools and plastic injection moulding machines to facilitate the complete integration of factory automation systems for UK manufacturers.

FANUC UK works in partnership with FANUC Europe Corporation to provide a range of customer support services, including sales, product support, parts, repairs, and training, as well as development of bespoke engineering systems. FANUC UK is a subsidiary of FANUC Europe Corporation and employs approximately 107 staff.

FANUC Corporation

The FANUC Corporation is a world leader in factory automation for CNC control systems, robots and production machinery (ROBODRILL, ROBOCUT and ROBOSHOT). Since 1956, FANUC has pioneered the development of numerically controlled machines in the automation industry. With 263 locations supporting 108 countries worldwide and more than 7,000 employees, FANUC offers a dense network in sales, technical support, research & development, logistics and customer service.

For more information on FANUC, or to see its current product range, please visit:

www.fanuc.eu/uk/en.

More information can be acquired here:

FANUC UK Limited

Sapphire Way

Ansty Business Park

Coventry