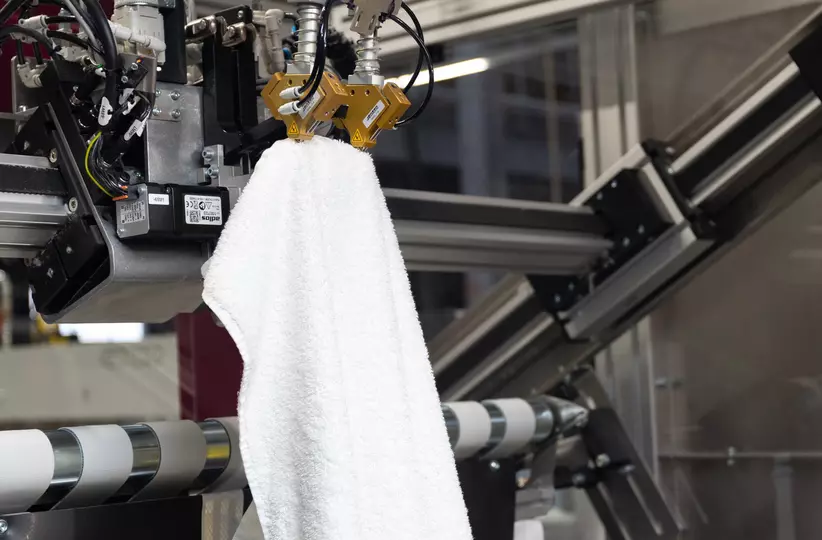

FANUC Robots Wash Away Inefficiency

Laat u inspireren!

Automatisering is het beste medicijn bij DEMO

Een belangrijke speler in de farmaceutische industrie, verbeterde zijn productiemogelijkheden aanzienlijk met FANUC's geautomatiseerde oplossingen. Door de integratie van FANUC robots optimaliseerde DEMO de vul-, verpakkings- en etiketteerprocessen, wat resulteerde in een verbeterde efficiëntie, nauwkeurigheid en algehele productiviteit van hun activiteiten.

De mooie kant van FANUC automatisering bij cosmeticafabrikant

Erkul Cosmetics in Turkije profiteert van tal van kwaliteits- en efficiëntievoordelen dankzij diverse hoogwaardige automatiseringsoplossingen van FANUC. Dit snelgroeiende cosmeticabedrijf wil een nieuwe standaard zetten in de productie binnen zijn sector, gesteund door de concurrentievoordelen die FANUC-technologie biedt.

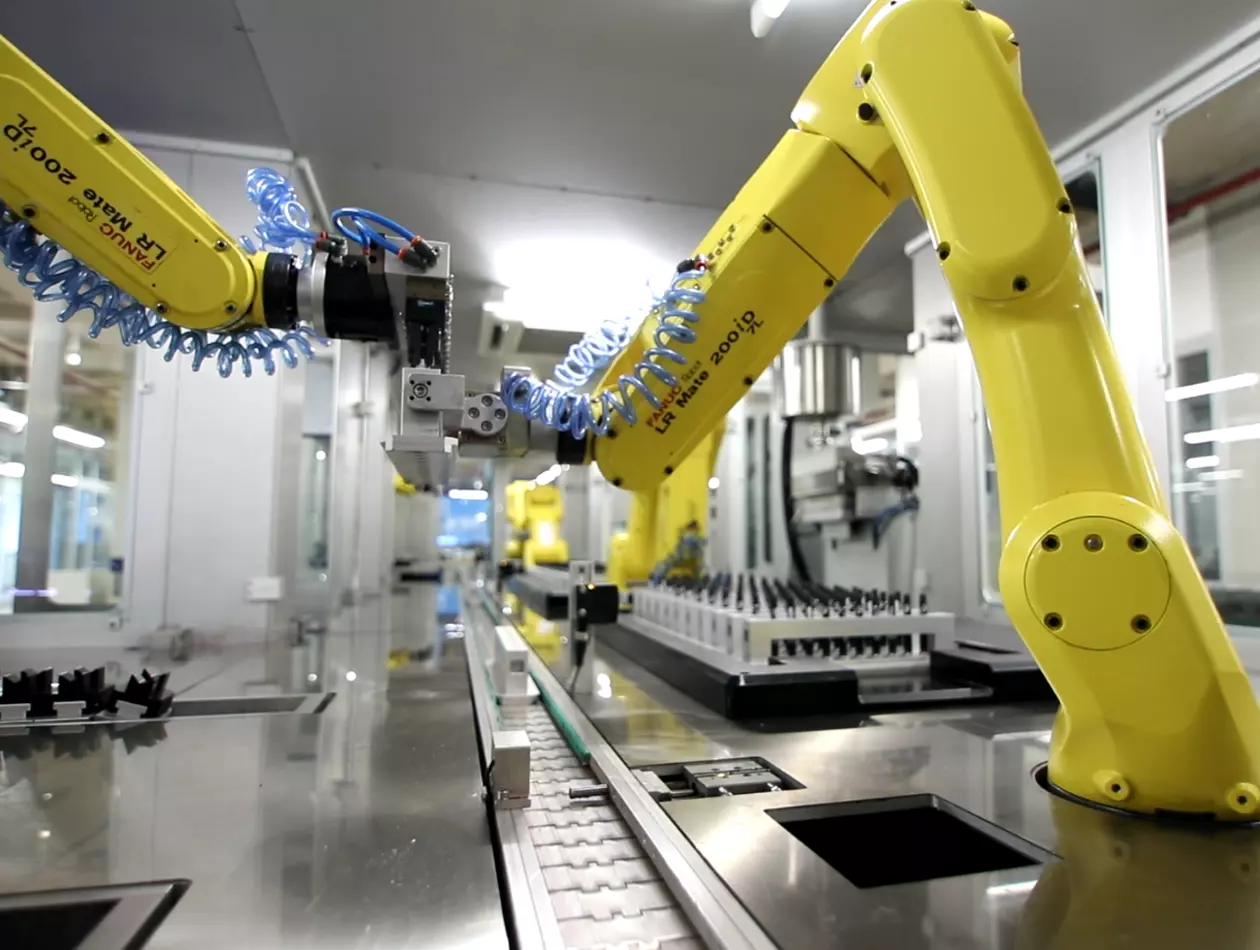

FANUC Robots: een meerwaarde bij muntproductie van Swissmint

Het is geen sinecure om het volledige muntproces te automatiseren, van individuele munten tot afgewerkte gepalletiseerde dozen. Dat was echter de taak waar Swissmint, de federale Munt van Zwitserland, voor stond. Om dit complexe concept te verwezenlijken, zet Swissmint krachtige FANUC robots in voor taken zoals pick-and-place, assemblage van dozen en palletisering.

FANUC Case Studies

Ontdek onze uitgebreide reeks automatiseringsoplossingen voor fabrieken, die worden gepresenteerd in gedetailleerde case studies en zijn ontworpen om elk productieproces te optimaliseren en te stroomlijnen.

Material Handling