Arc Welding

Streamline your Arc Welding Process with FANUC Arc Welding Robots

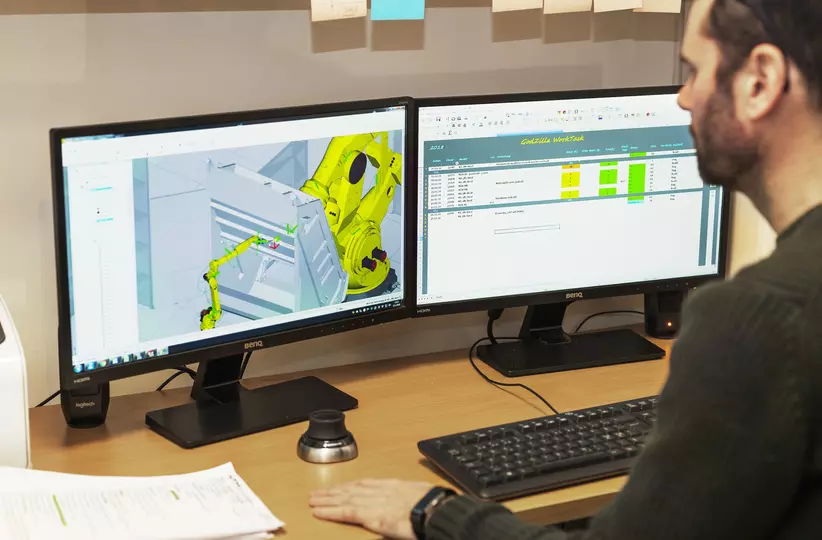

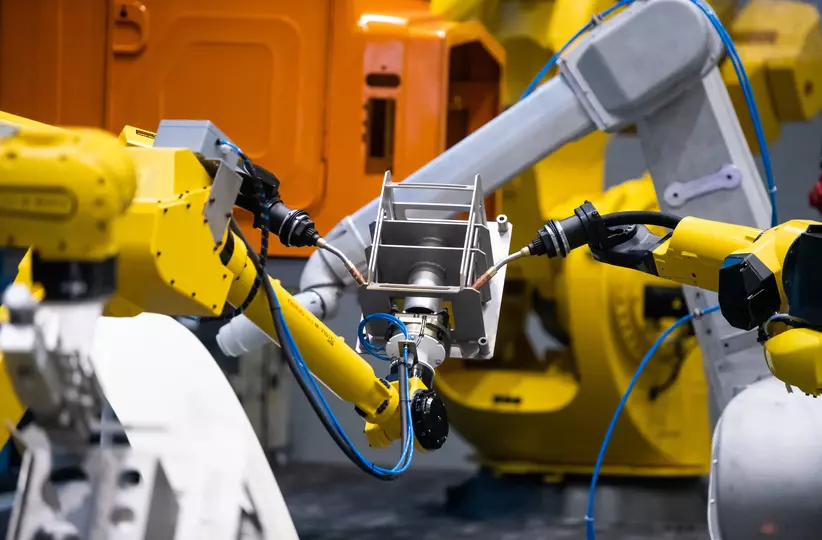

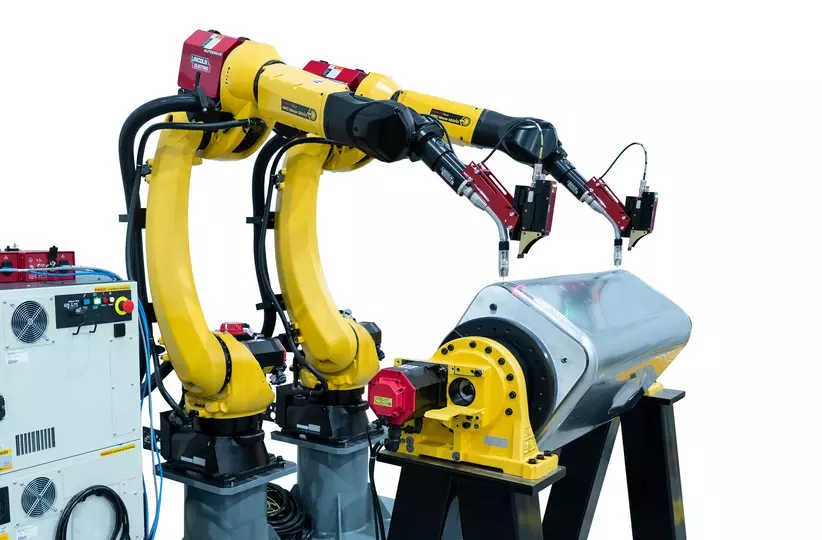

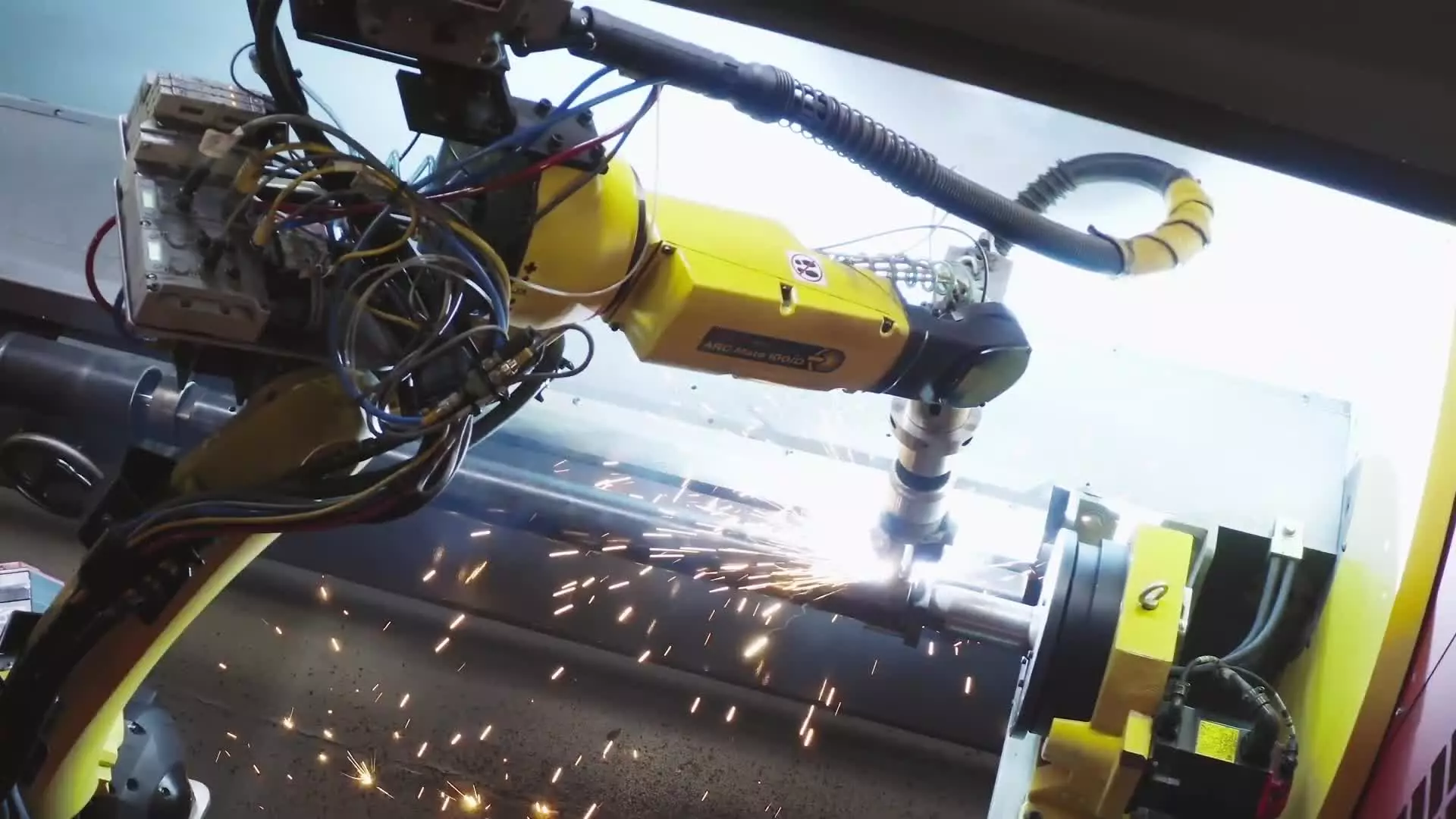

FANUC arc welding robots are renowned for their precision, speed, and versatility. Key features include advanced motion control for accurate welds, user-friendly programming interfaces, slim and hollow wrists and a robust construction for durability in harsh environments. They offer high payload capacities, extensive reach, and multi-axis flexibility, ensuring they can handle complex welding tasks. Integrated safety features, such as collision detection, enhance operational security, while their compatibility with various welding equipment makes them ideal for diverse industrial applications.

Get Inspired

Get Inspiration from Other's Success

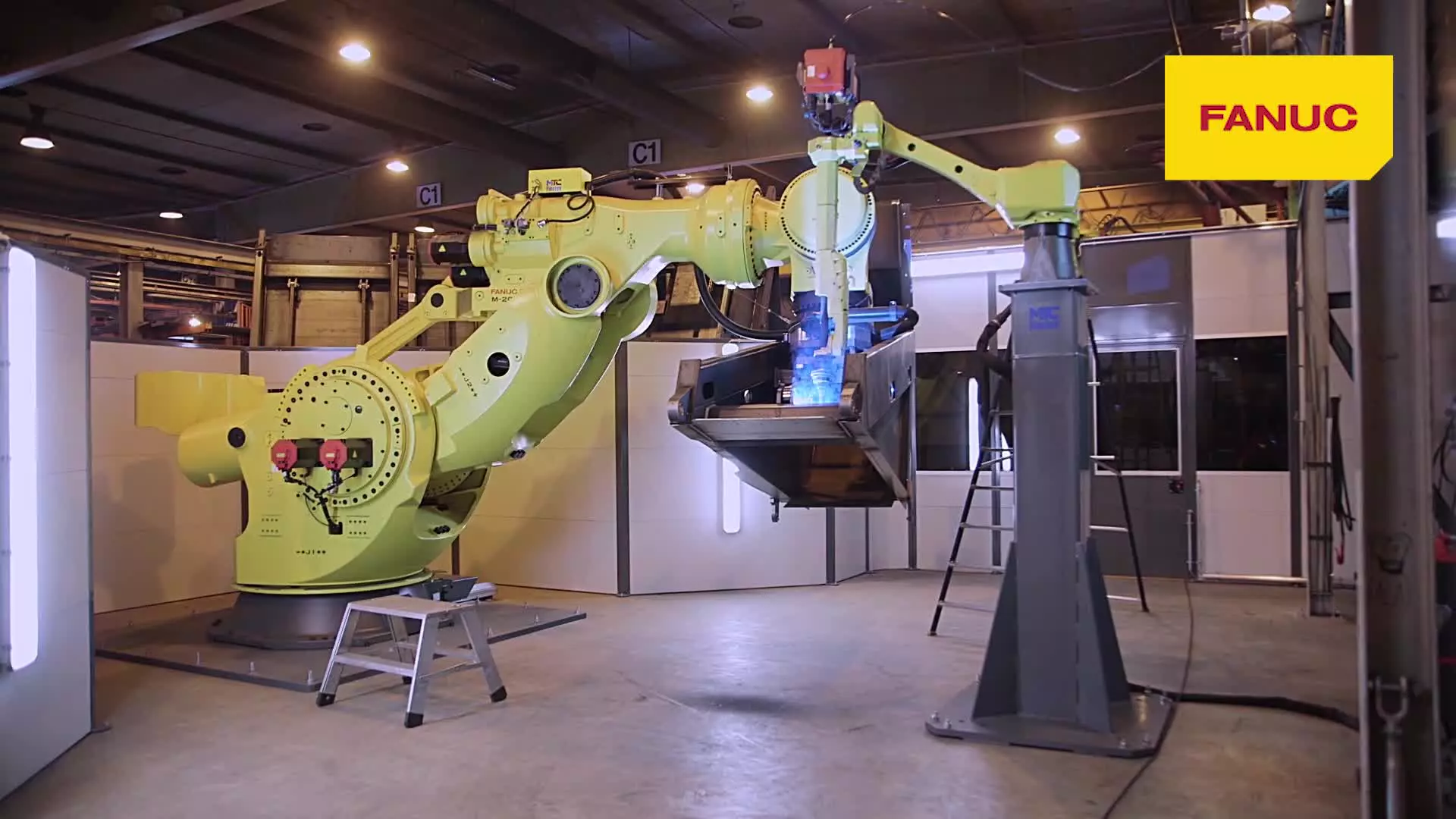

Heavy Lifting for Truck Construction

NTM was able to increase the production capacity for its refuse collection vehicles by opting to automate the night shift. By using a heavy-duty robot that can lift up to two tonnes and a robotic welding solution, the company's Finnish plant can now work unmanned at night or on weekends.

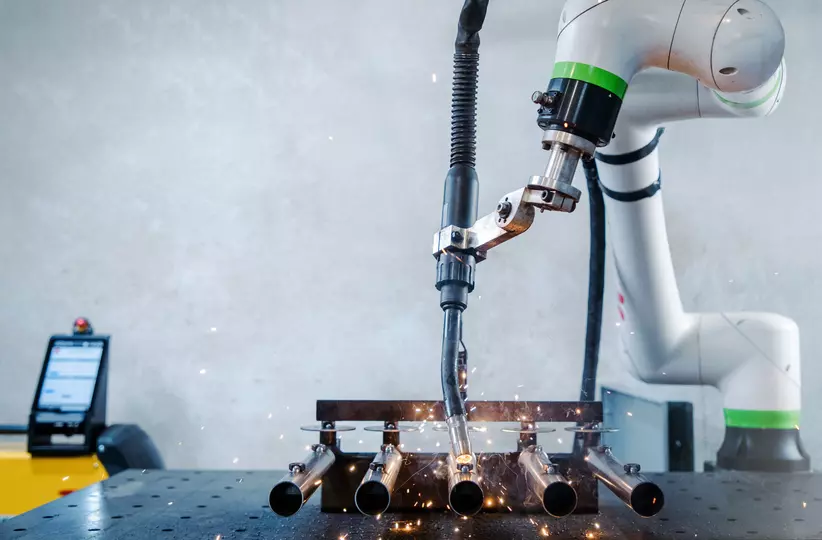

FANUC's CRX Cobot Boosts Production Flexibility

Bonvicini Carpenteria today enjoys even higher levels of quality and flexibility. The company can flex between automation solutions whenever production volumes dictate. In particular, Bonvicini Carpenteria is taking advantage of easy and fast robot programming with features such as drag and drop functionality and a simple tablet interface.

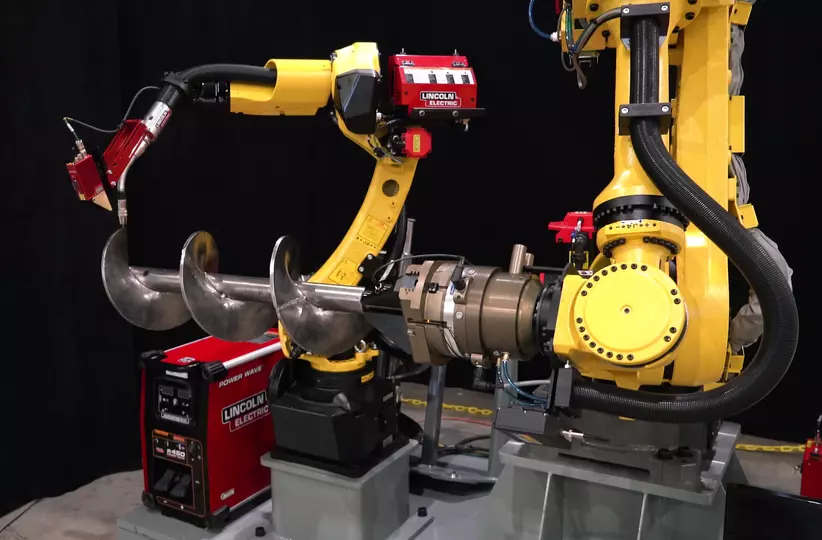

Securely Welded With the FANUC ARC Welding Robot

Robots are ideal for the automation of welding tasks. Their high-quality work becomes even more amazing when large welding components come into play.

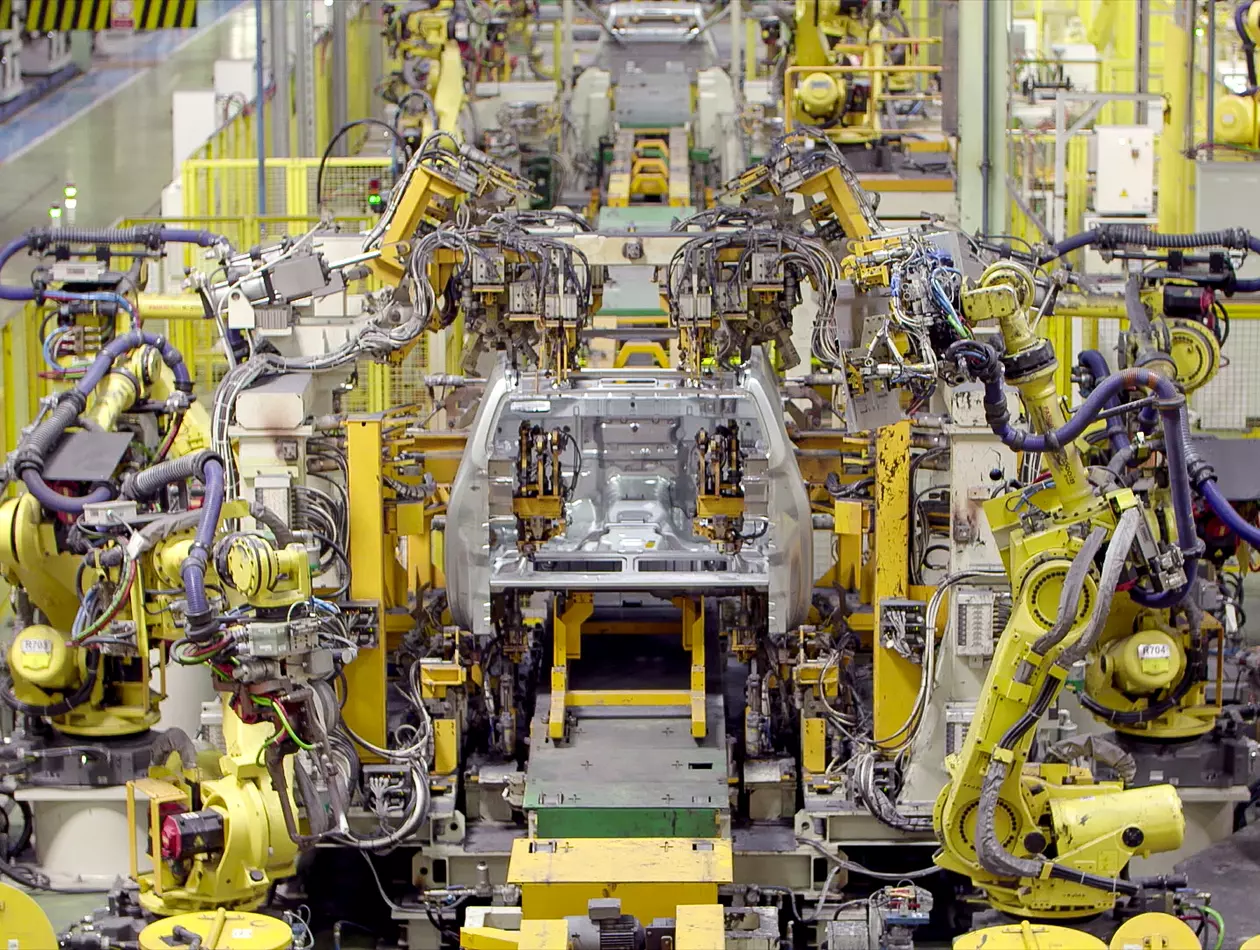

FANUC Robots Optimise High-Volume Production at Nissan

Industrial robots have become an integral part of the modern automotive production line. Each task they perform is vital, not only to meet the necessary levels of efficiency and productivity, but also to meet the highest standards of quality and safety. FANUC is the robot of choice for many of the world’s leading automotive giants, with Nissan providing a notable case in point.

Transform your Industry with FANUC Arc Welding Robots

Automotive

Electric Vehicles

All Industries

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.