/

𝑖HMI

𝑖HMI

Delen

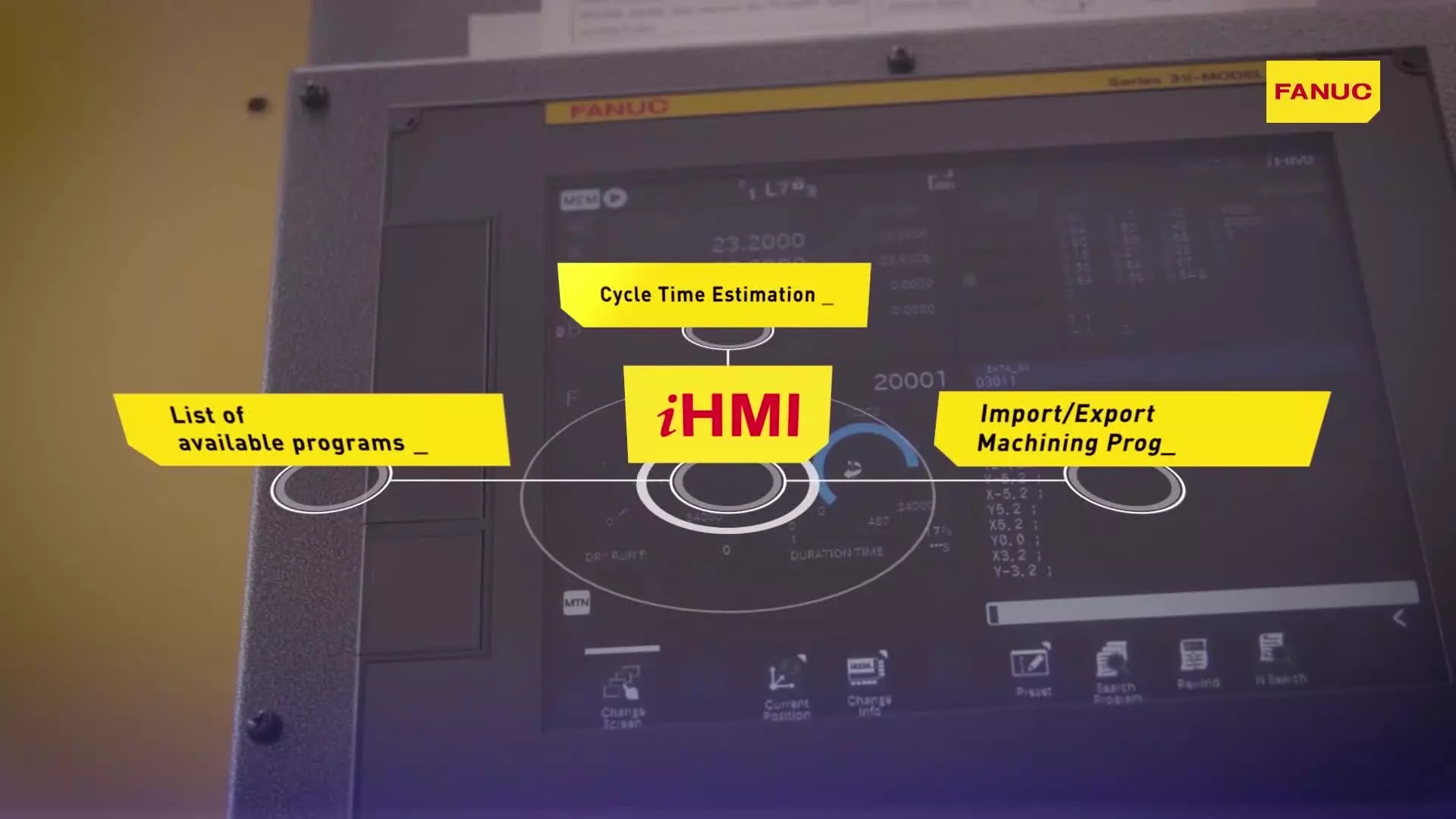

Ontdek de ultieme oplossing voor uw bedrijf met onze FANUC 𝑖HMI. De FANUC 𝑖HMI is ontworpen om de productiecapaciteit te verhogen, de trainingstijd voor operators te verkorten en de algehele efficiëntie op de werkvloer te verbeteren. De FANUC 𝑖HMI is uw toegangspoort tot verbeterde CNC machineprestaties. Investeer vandaag nog in de FANUC 𝑖HMI en ervaar ongeëvenaarde productiviteit en efficiëntie.

Wij bieden schermen in verschillende paneelformaten 10.4" / 15" / 19" / 21.5" om aan uw behoeften te voldoen.

- Inzichten

- Belangrijkste Voordelen

- Belangrijkste Kenmerken

- Documenten

Inzichten

Gestroomlijnde interactie voor CNC uitmuntendheid

Verbeter de efficiëntie, verkort de insteltijden en verhoog de productiviteit met de nieuwste technologie. Bekijk de video voor meer informatie over onze FANUC 𝑖HMI en hoe deze uw bedrijf ten goede komt.

Belangrijkste Voordelen

Voordelen voor uw bedrijf

Revolutionaire Efficiëntie met Intuïtieve Interface

Verhoog de productiviteit met het gebruiksvriendelijke ontwerp van de FANUC 𝑖HMI. Het vermindert de instel- en trainingstijd en vereenvoudigt complexe taken voor een verbeterde operationele efficiëntie.

Uptime Maximaliseren met Geavanceerde Diagnose

Zorg voor een continue werking met de diagnosetools van de 𝑖HMI. Identificeer en verhelp problemen snel waardoor stilstand en onderhoudskosten worden beperkt voor topprestaties.

Naadloze Integratie voor Diverse Industriële Toepassingen

FANUC 𝑖HMI integreert naadloos in verschillende industrieën. De flexibele interface voldoet effectief aan uw unieke productievereisten.

Verbeterd Gegevensbeheer voor Geïnformeerde Besluitvorming

Maak gebruik van realtime informatie en analyses van het gegevensbeheer van 𝑖HMI. Hierdoor kunt u beter geïnformeerde keuzes maken, processen optimaliseren en een concurrerende marktpositie behouden.

Maak uw Activiteiten Klaar voor de Toekomst met Schaalbare Oplossingen

Investeer in de toekomst met de schaalbare architectuur van 𝑖HMI. Pas u aan aan nieuwe technologieën en geef werknemers nieuwe mogelijkheden zodat u voorop blijft lopen met trends in de sector.

Belangrijkste Kenmerken

Functies ontworpen voor uw succes

Verbeter uw CNC-ervaring. Zorg voor een revolutie in uw CNC activiteiten met de FANUC 𝑖HMI, onze intelligente mens-machine interface ontworpen om de productiviteit en uptime te maximaliseren.

Deze gebruiksvriendelijke interface heeft een slank, vlak touchscreen scherm en intuïtieve navigatie, waardoor het voor operators eenvoudig te gebruiken is:

Complexe bewerkingsprocessen eenvoudig programmeren

dankzij duidelijke menu's, een modern ontwerp en geanimeerde functies.

Productieschema's optimaliseren

met verbeterde zichtbaarheid en controle over machinefuncties.

Fouten en correcties minimaliseren

door een gestroomlijnde gebruikerservaring.

Onderhoudsplanning en -uitvoering verbeteren

voor maximale uptime van de machine.

Documenten

Download aanvullende informatie

Krijg toegang tot essentiële technische specificaties en waardevolle informatie over onze producten via onze downloads. Deze zullen je helpen om de juiste beslissingen te nemen en het meeste uit je FANUC producten te halen.

Contacteer ons

Oplossingen

CUSTOMER SERVICE

ONDERWIJS

NIEUWS & MEDIA

CONTACT