Actualités et médias

- Études de cas

- Bibliothèque des médias

- Actualités & communiqués de presse

- Evénements

Études de cas

Découvrez des réalisations remarquables alimentées par les solutions d'automatisation d'usine de FANUC. Voyez comment notre technologie transforme les industries et propulse le succès.

Les robots FANUC permettent un usinage CNC 24 heures sur 24 et 7 jours sur 7 chez RADMOT

Les cellules d'usinage CNC automatisées comprenant diverses machines-outils et robots nécessitent une conception et une intégration astucieuses. Pourquoi ne pas simplifier le processus en se tournant vers le plus grand fabricant mondial de machines-outils CNC et de robots : FANUC. C'est précisément la stratégie adoptée par RADMOT, un important fournisseur de services d'usinage basé en Pologne, lorsqu'il a voulu mettre en place une nouvelle cellule de fraisage CNC comprenant trois centres d'usinage et deux robots pouvant fonctionner sans personnel 24 heures sur 24, 7 jours sur 7, sans qu'il y ait de collisions entre les robots.

Le succès de la cellule du robot FANUC est à l'origine d'une nouvelle source de revenus

À quoi pensent la plupart des entreprises d'usinage à façon lorsqu'elles cherchent à atteindre un niveau supérieur d'efficacité, de productivité et de fiabilité ? La réponse est bien sûr l'automatisation. C'est précisément pour cette raison que la société allemande WU Mechanische Werkstätte GmbH a construit une cellule d'automatisation - équipée d'un robot industriel FANUC - pour charger et décharger l'une de ses propres machines-outils. Deux ans plus tard, un visiteur a tellement apprécié le concept qu'il a demandé à WU de lui en construire une. Ce fut le début d'une nouvelle source de revenus basée sur la conception et la construction de cellules d'automatisation équipées de robots industriels haute performance de FANUC.

Assemblage entièrement automatisé de moulins à café

Dans la fabrication d'appareils ménagers courants tels que les moulins à café, un certain nombre de conditions préalables déterminent le succès de la production. Par exemple, seuls des processus clairement structurés, efficaces et orientés vers des objectifs précis permettront d'atteindre les niveaux requis de fiabilité de la production. La réalisation de cette ambition devient nettement plus réaliste grâce à l'automatisation, comme le leader du marché Eugster/Frismag AG peut en témoigner après avoir adopté 14 robots industriels FANUC LR Mate et FANUC ZDT (Zero Down Time), qui permettent désormais l'assemblage automatisé en continu d'un moulin à café toutes les 7 secondes.

Trois robots FANUC améliorent l'efficacité de l'emballage chez Inoverde

Dans une usine de distribution de produits frais qui évolue rapidement, l'efficacité des opérations d'emballage automatisées est primordiale pour répondre à la demande. Grâce à cette approche, les utilisateurs de robots bénéficient également d'une réduction des efforts physiques des employés, d'une manipulation plus douce des produits délicats tels que les fruits et les légumes, et d'un processus plus uniforme et reproductible. Parmi les dernières usines à bénéficier de toute cette valeur ajoutée figure le site de Bätterkinden, en Suisse, du grand distributeur alimentaire Inoverde, où les opérations de remplissage, d'emballage et de palettisation des carottes bénéficient de l'introduction de trois robots industriels FANUC.

La CNC FANUC multi-capacités donne une nouvelle dimension au tournage vertical

Le développement d'une nouvelle approche d'un processus séculaire tel que le tournage requiert des niveaux surhumains de créativité et d'innovation. De plus, la concrétisation de ces nouvelles visions et concepts de machines nécessite une technologie de commande extrêmement avancée. Dans cette optique, le constructeur de machines-outils FFG Werke savait exactement vers qui se tourner pour trouver un système CNC doté des capacités et des performances nécessaires pour compléter son nouveau centre d'usinage vertical révolutionnaire : FANUC.

Bibliothèque des médias

Découvrez et téléchargez des images, des vidéos et des documents officiels de FANUC dans notre médiathèque.

Trouver des contacts avec les médias

Contactez nos spécialistes des relations publiques et de la communication de FANUC Europe

Articles de presse

Le nouveau robot FANUC à charge utile et à longue portée simplifie les applications lourdes.

EuroSkills - Concours européen pour les jeunes experts en robotique

Le nouveau robot palettiseur pour charges utiles lourdes de FANUC permet de soulever plus de char...

FANUC obtient la note GOLD en matière de développement durable

FANUC présente l'automatisation pratique à Automatica

FANUC soutient le projet de la Deutsche Bahn

Les nouveaux robots de la série M-710 offrent un design attrayant et des améliorations notables

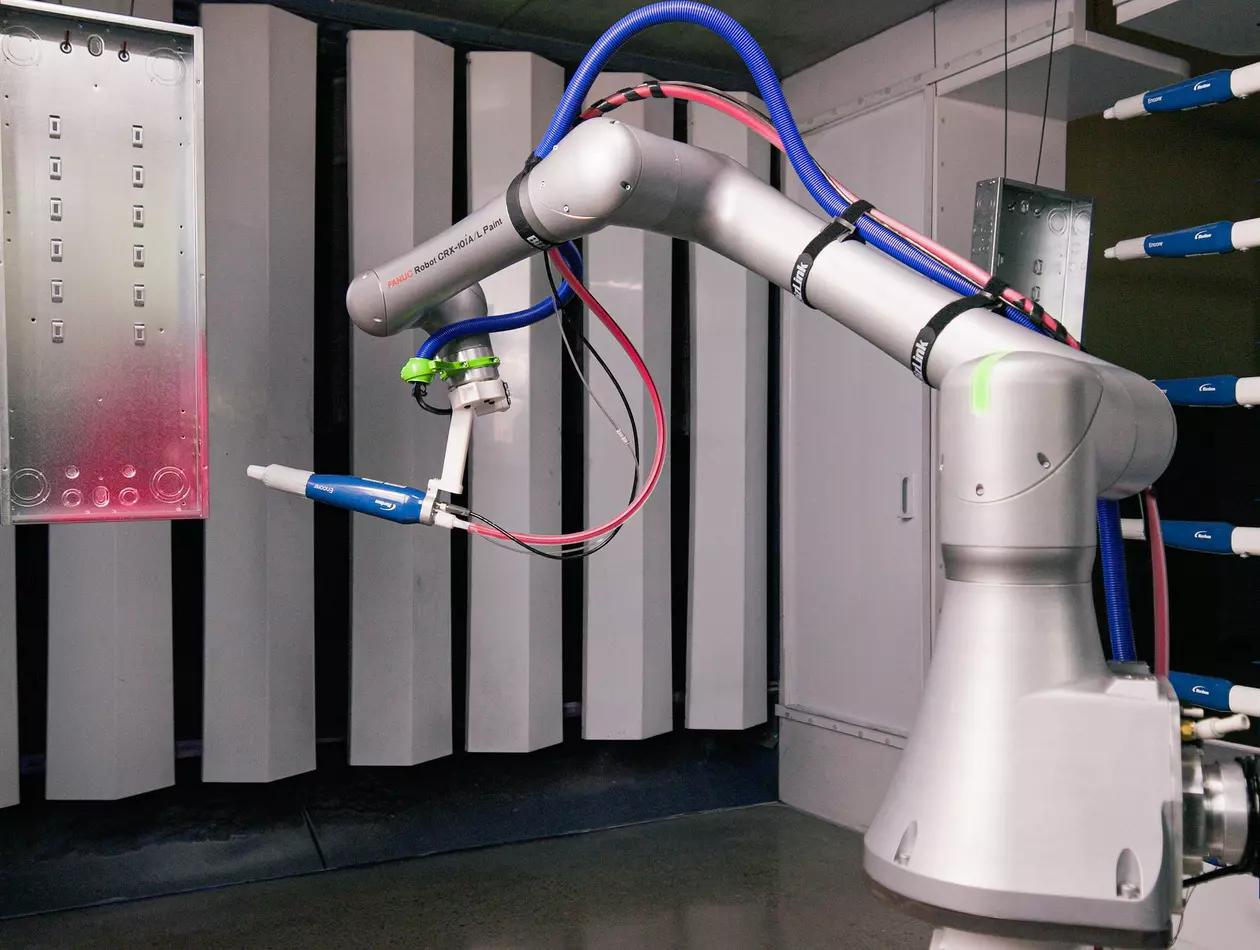

FANUC dévoile le premier robot de peinture collaboratif antidéflagrant du marché

Le robot FANUC SCARA résiste aux procédures de nettoyage