“In the laundry industry, everything that arrives usually requires clearing the next day,” states Bernhard Aschenbrenner, Managing Director, Wäscherei Aschenbrenner. “For this reason, we are grateful for any help, especially if it’s well qualified and permanent.”

“In the laundry industry, everything that arrives usually requires clearing the next day,” states Bernhard Aschenbrenner, Managing Director, Wäscherei Aschenbrenner. “For this reason, we are grateful for any help, especially if it’s well qualified and permanent.”

Little comes more qualified and permanent than a fully automated solution. Step forward Sewts GmbH and its VELUM automation system.

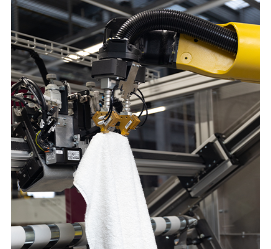

Industrial laundries wash and dry textiles in a highly automated environment to cope with large quantities of dirty linen. However, there remains a requirement for manual work to fill a few gaps in the automation chain. For instance, each folding machine typically requires an employee who feeds the laundry and spreads it out without wrinkles. Sewts’ VELUM provides the solution by feeding towels and other terry-cloth items into folding machines. The success of the system relies on two FANUC industrial robots.

“We chose FANUC because they believed in VELUM from the very beginning,” says Till Rickert, Co-Founder and CPO of Sewts. “We talked to several robot manufacturers, but FANUC showed their innovation spirit from the start. They even provided us with robots so we could develop a prototype.”

Another prerequisite for VELUM was its need for a highly reliable robot that could cope with very aggressive dust.

“FANUC, with its many years of proven and reliable robots, was very convincing,” says Rickert. “From the outset we had professional and friendly co-operation with the FANUC team, who provided us with dedicated contacts in both sales and technical service.”

The first robotic task inside the two fully contained VELUM automation cells at Wäscherei Aschenbrenner, affectionately named Bobby and Betty, is the pre-separation of washed and dried towels. An AI vision system guides a FANUC M-10iD/12 robot to the optimal location to activate the gripping of an individual towel. Once picked, the robot places the towel on a conveyor, which transports it to a second robot station. Here, another M-10iD/12 robot picks the towel from the conveyor and places it between a pair of grippers mounted on a horizontal linear rail. These grippers move in opposite directions to fully extend the towel ready for folding.

Ultimately, the VELUM system provides a very efficient and effective way of automating this previously manual task, overcoming labour shortages and reducing process costs.