ROBOCUT Wire-Cut EDM Machines

Craft a wide number of intricate components with unmatched accuracy and speed with the help of our multipurpose EDM wire-cutting machine.

Get Inspiration from Others' Success

Euroedil

EUROEDIL Enjoys Faster Cutting Rates and Higher Throughput with FANUC Machines

With its new FANUC machines in-site, EUROEDIL has increased its cutting rate and throughput to meet rising volume demands from customers. Moreover, the accuracy and precision of the company’s die-cutting tools have improved noticeably.

Perfect Fit for Your Application

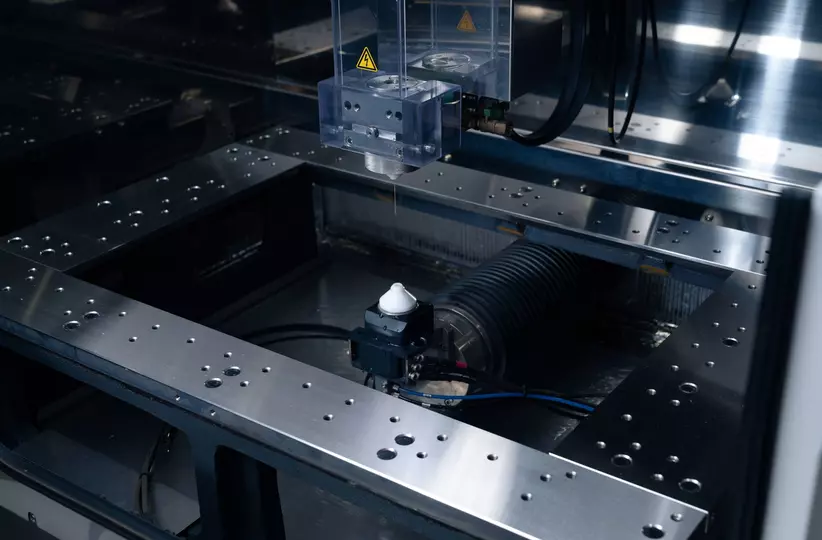

Wire Cutting EDM

Wire EDM (Electrical Discharge Machining) is a precision manufacturing process that uses a thin, electrically charged wire to cut intricate shapes and contours in hard metals and conductive materials. The wire generates a series of rapid electrical discharges, which erode the material with extreme accuracy without applying mechanical force. This non-contact method allows for the production of highly detailed, complex parts with excellent surface finishes, making it essential for industries that require precise machining, such as aerospace, medical, and mould-making.

Tailored Solutions for Your Industry

Electronics

We provide automated solutions for electronics manufacturing and clean room settings.

Complex Machining for the Aerospace Industry

Optimise Aerospace Manufacturing Processes with FANUC’s State-of-the-Art Complex Machining Solutions!

Complex Machining for the Automotive Industry

Precision and Efficiency in Automotive Manufacturing!