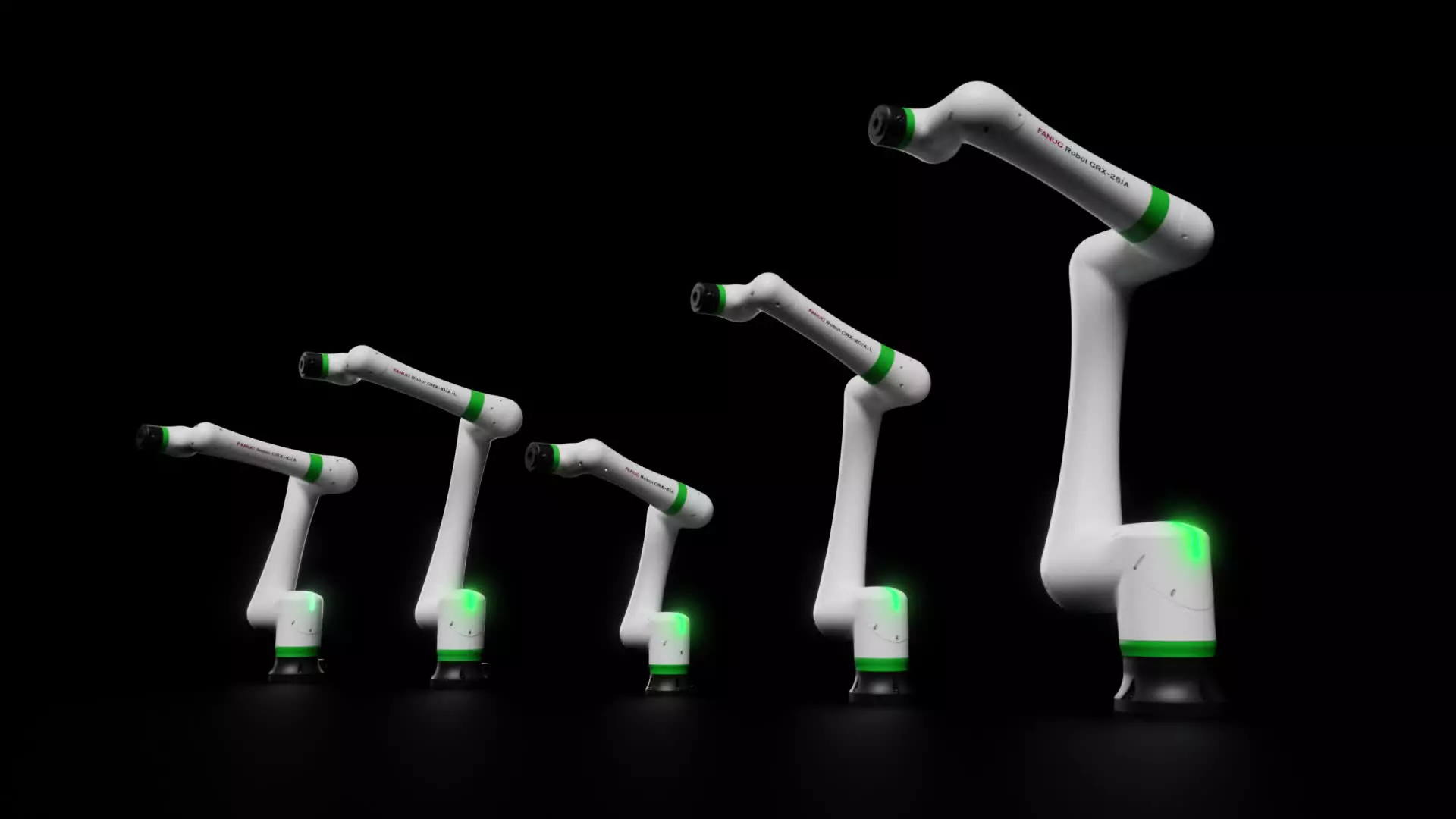

FANUC Collaboratieve Robots

Waar industriële cobots zijn, daar is FANUC

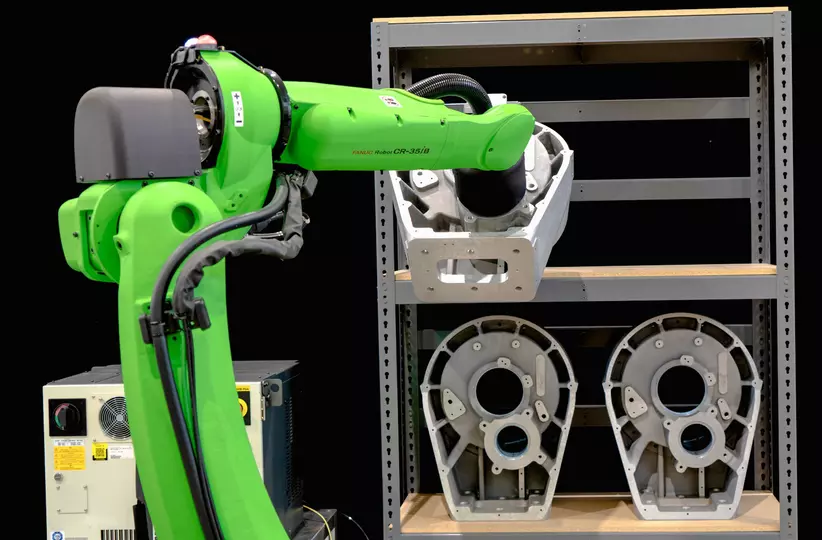

Wanneer u een industriële cobot nodig hebt, hoeft u niet verder te zoeken dan FANUC. Als 's werelds toonaangevende fabrikant van cobots bieden we een verscheidenheid aan uiterst nauwkeurige cobotmodellen die producten tot 50 kg kunnen hanteren. Of u nu ervaring hebt met traditionele industriële robots of nog nooit met een robotarm hebt gewerkt, wij hebben een cobotoplossing die past in uw productieomgeving. Met 50 jaar ervaring in de robotica begrijpen wij de productieomgevingen van vandaag — van kleine series met hoge variatie tot grote series met lage variatie. Dus wanneer het moment daar is om een collaboratieve robottoepassing te overwegen, kunt u op FANUC rekenen om u te helpen de meest efficiënte en kosteneffectieve oplossing te vinden.

Laat u inspireren!

Haal inspiratie uit het succes van anderen

Samen sterk: FANUC cobot is de ideale oplossing voor AS Adhesive Solutions

Automatisering is niet alleen weggelegd voor toepassingen met grote volumes. AS Adhesive Solutions, een gespecialiseerd adviesbureau en partner voor de lijmindustrie, erkent dat ook veel kmo’s die kleinere hoeveelheden verwerken, kunnen profiteren van volledig of gedeeltelijk geautomatiseerde processen. In zulke gevallen biedt een collaboratieve robot (cobot) vaak de meest geschikte oplossing.

Cobot als collega: lichter werk, betere resultaten

Kwaliteitscontroles en verpakken kunnen fysiek zwaar zijn. De integratie van collaboratieve robots kan de ergonomie van dergelijke activiteiten echter aanzienlijk verbeteren.

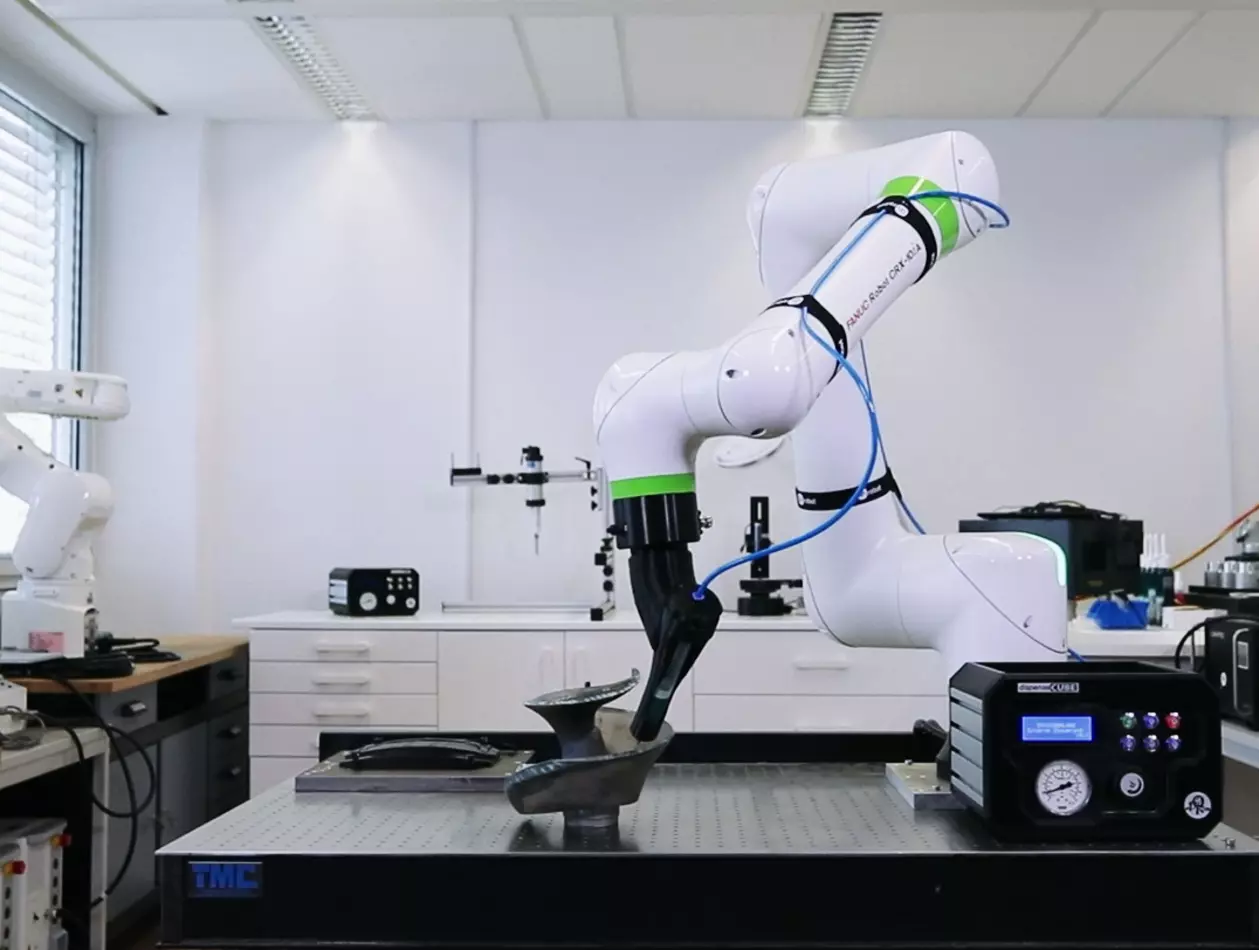

GER4TECH zet alles in beweging met FANUC Cobot

Het ontwikkelen van een nieuwe robot vraagt om expertise, ervaring en vaak samenwerking met partners die gespecialiseerd zijn in specifieke technologiegebieden. Toen GER4TECH op zoek ging naar een specialist in collaboratieve robots om geavanceerde mogelijkheden toe te voegen aan zijn nieuwe autonome mobiele robot (AMR), klopte het bedrijf aan bij FANUC.

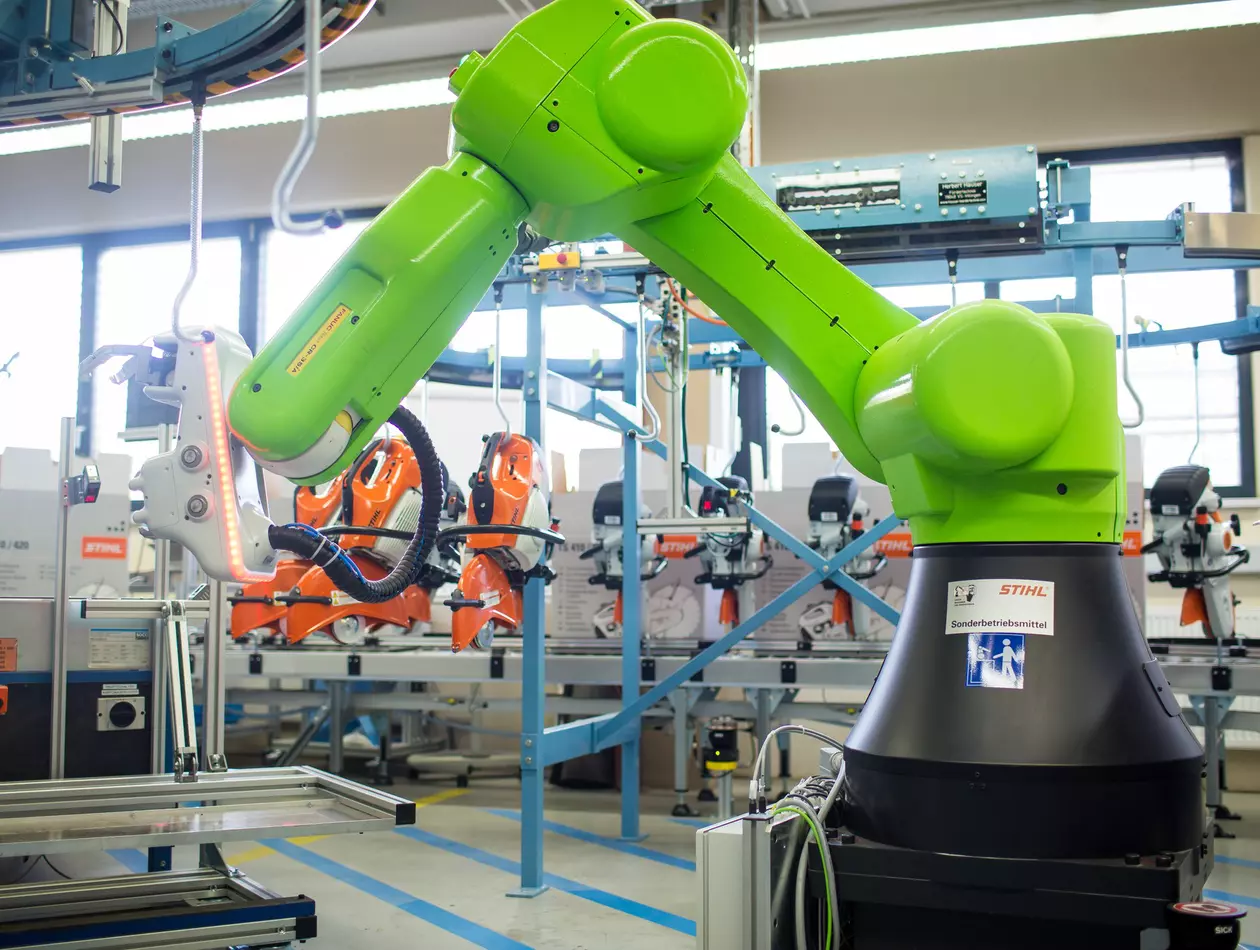

FANUC's CRX Cobot verhoogt productieflexibiliteit

Bonvicini Carpenteria geniet vandaag van nog hogere niveaus van kwaliteit en flexibiliteit. Het bedrijf kan eenvoudig schakelen tussen automatiseringsoplossingen wanneer de productievolumes daarom vragen. Bonvicini Carpenteria profiteert met name van eenvoudige en snelle robotprogrammering met functies zoals drag-and-drop en een intuïtievetabletinterface.

De perfecte match voor uw toepassing

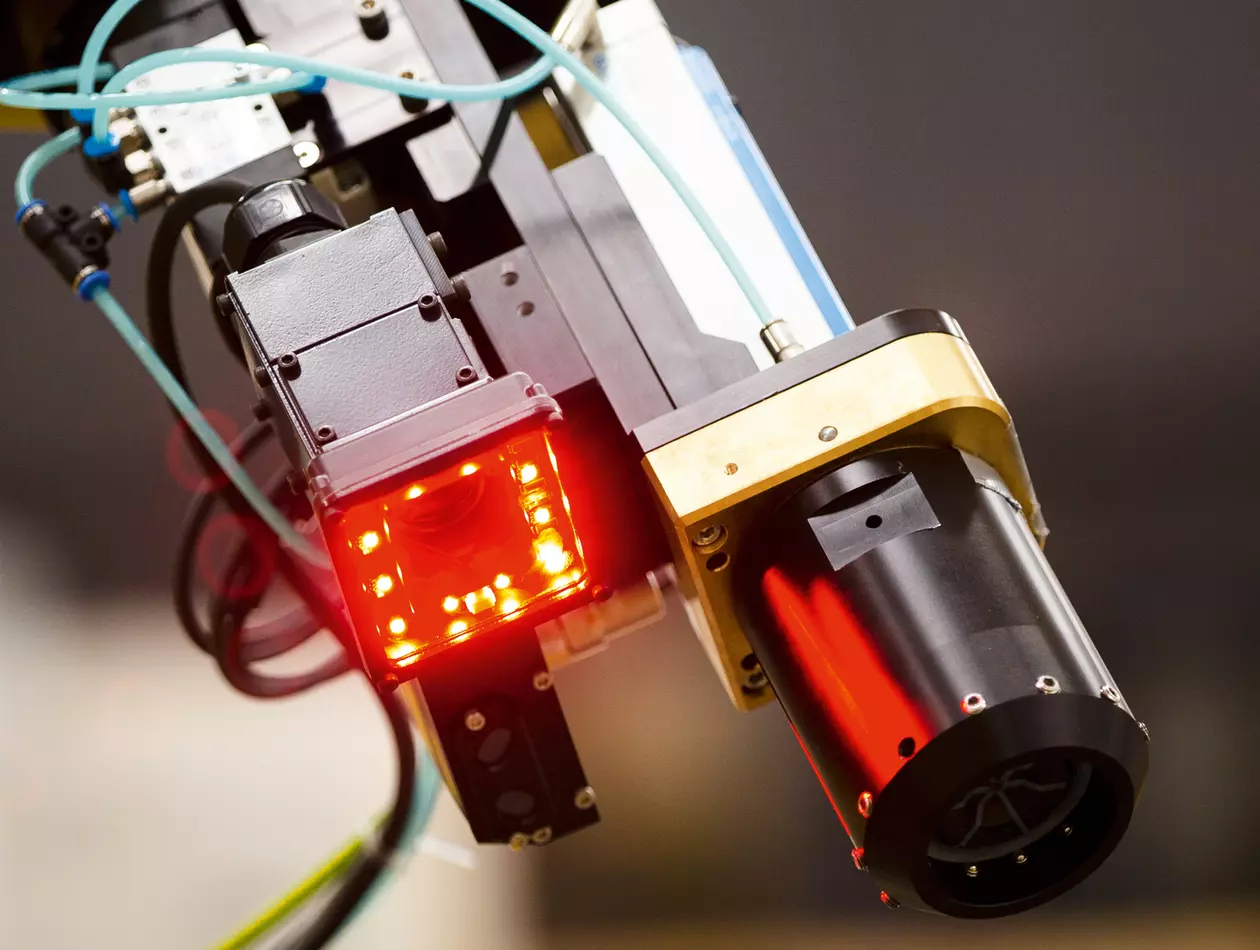

Booglassen

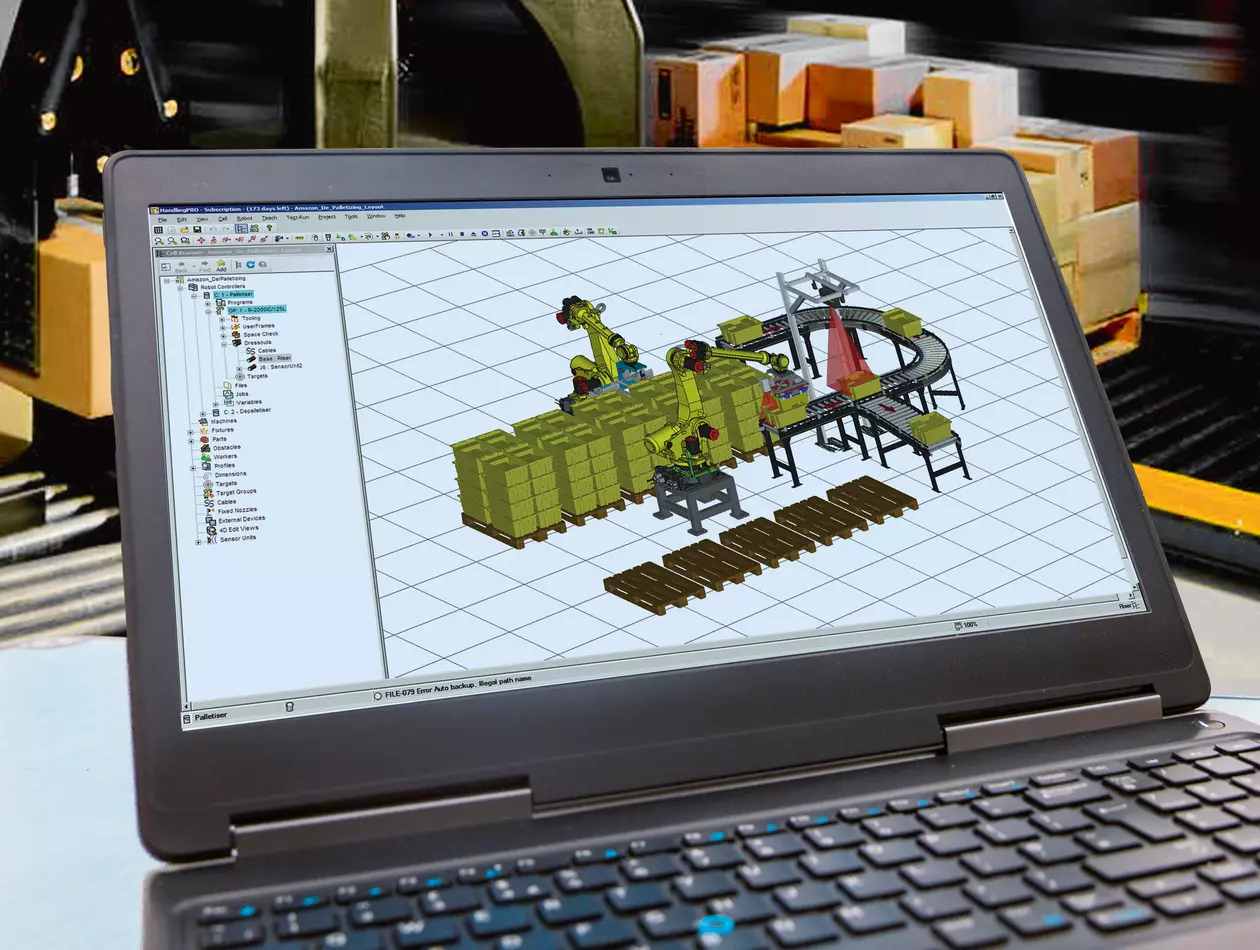

Palletiseren

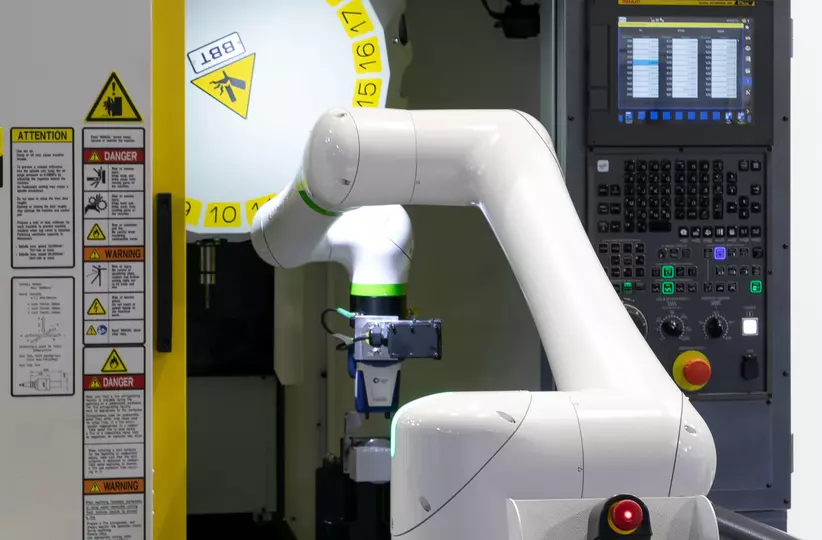

Machinebelading

Vision Inspectie

Material Handling

Assemblage

Oplossingen op maat voor uw industrie

Robots en automatisering voor de automotive industrie

Robots en automatisering voor de Luchtvaartindustrie

Elektrische voertuigen

Food & Beverage

Elektronica