Advanced Injection Moulding for the Medical Industry

Expertise in Medical Device Moulding

Quality, reliability and repeatability are critical in medical product manufacture. For example, the transparency of many medical products means tackling gas venting and changes in viscosity. Here, pre-injection and AI Metering Control functions counter these issues to ensure consistency. In addition, with 6 different screws as standard, ROBOSHOT users can easily accommodate different products.

- Application

- Related products

- Benefits

- Case Studies

Optimised Injection Moulding for Medical Excellence

Harnessing the power of FANUC's precision technology, our injection moulding process delivers maximum quality, reliability, and repeatability, essential for medical manufacturing. With our advanced systems, concerns over gas venting or changing viscosity become obsolete, ensuring flawless production every time. The integrated hot runner control streamlines operations, while our commitment to quality assurance and historical traceability is unwavering, providing easy monitoring and consistency. Profitable versatility is at the core of our process, offering six different screw sizes for diverse product requirements, and with process graphics as standard, we ensure a clear view of production efficiency and excellence.

Hocheffiziente Produktion mit FANUC

Präzisions-Spritzgießen

Einsatzformteil

High-Efficiency Production with FANUC

FANUC's injection moulding solutions redefine high-efficiency production in the medical industry. Our machines ensure maximum quality and consistency, equipped to handle the intricacies of medical-grade materials. The integrated hot runner control and process graphics come standard, offering manufacturers a clear and controlled view of their operations, ensuring every cycle meets the highest standards of medical manufacturing.

Precision Injection Moulding

For medical components where precision is non-negotiable, FANUC's precision injection moulding stands unmatched. With absolute control over processes, including gas venting and viscosity, our machines guarantee repeatability and top-tier product quality. The ability to choose from six different screw sizes allows for profitable versatility, making FANUC's system ideal for a range of precision medical products. Furthermore, easy quality assurance and historical traceability underscore our commitment to reliability in every mould.

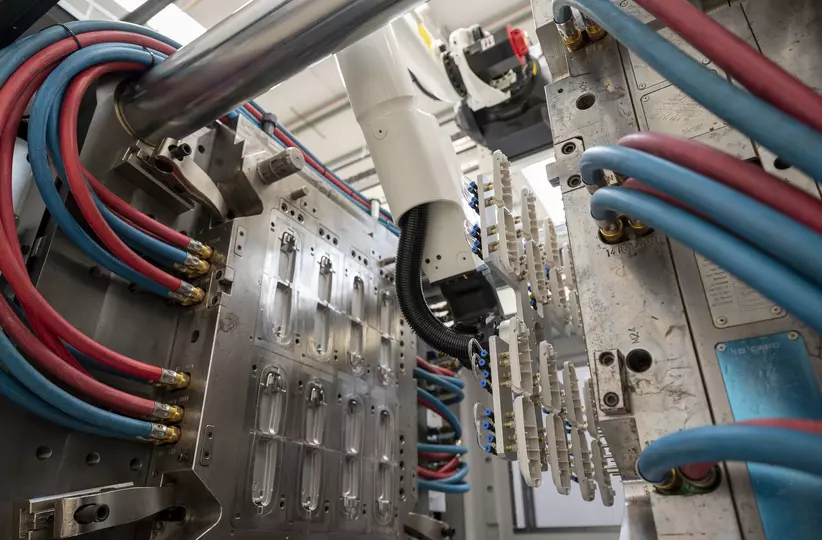

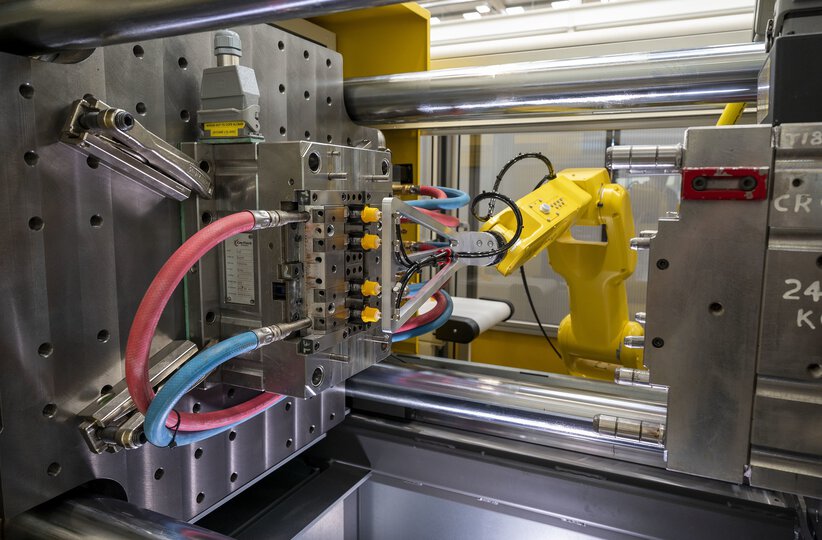

Insert Moulding

FANUC's ROBOSHOT excels in insert moulding applications, offering precision and reliability for embedding metal parts into molded plastic with exceptional accuracy.

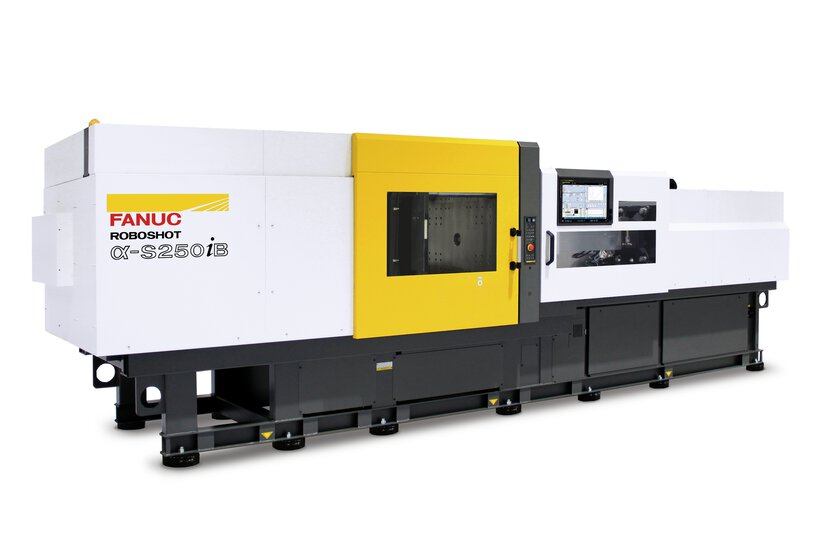

Our ROBOSHOT Injection Moulding Machines

ROBOSHOT 𝛼-S15𝑖B

ROBOSHOT 𝛼-S30𝑖B

ROBOSHOT 𝛼-S50𝑖B

ROBOSHOT 𝛼-S100𝑖B

ROBOSHOT 𝛼-S130𝑖B

ROBOSHOT 𝛼-S150𝑖B

ROBOSHOT 𝛼-S150𝑖B Small Capacity

ROBOSHOT 𝛼-S220𝑖B

ROBOSHOT 𝛼-S250𝑖B

ROBOSHOT 𝛼-S300𝑖B

ROBOSHOT 𝛼-S300𝑖B Small Capacity

ROBOSHOT 𝛼-S300𝑖B Large Capacity

ROBOSHOT 𝛼-S450𝑖B

ROBOSHOT 𝛼-S450𝑖B Large Capacity

Highlights

Medizinisches Paket

ROBOSHOT Roboter-Paket

LSR-Paket

Benefits for your Industry

Precision and Adaptability

Integrated Efficiency

Quality Assurance and Traceability

Data-Driven Precision

Optimised Process Monitoring

Cleanroom Compatibility

Automation-Ready FANUC ROBOSHOT

Compact Design FANUC ROBOSHOT

FANUC ROBOSHOT Maschinen halten die Dinge einfach für SIMON

Großvolumige Kunststoffteile, dünne Wände, keine Defekte, kurze Lieferzeiten in der Automobilindustrie, hohe Anforderungen an die Energieeffizienz. Eine wachsende Zahl von Herstellern begegnet diesen Herausforderungen mit der Investition in die vollelektrischen Hochleistungs-Spritzgießmaschinen ROBOSHOT von FANUC. Zu ihnen gehört auch SIMON Plastics.

Our Solutions for Other Industries

Factory Automation Solutions for any Manufacturing Process

Industries for Automation - FANUC serves any industry to help solve your automation challenges.