Options CNC pour la personnalisation

Nous avons le logiciel qu'il vous faut pour adapter votre CNC FANUC à vos besoins. Cela va des petites modifications où vous ajoutez des écrans en utilisant FANUC PICTURE, aux modifications où vous ajoutez des cycles technologiques personnalisés avec Macro executor. Vous pouvez ajouter de nouvelles fonctionnalités à votre CNC avec l'exécuteur de langage C, ou même créer l'IHM par vous-même en utilisant FOCAS.

- Points forts

- Options

Points forts

Avantages pour votre entreprise

Efficacité de la suralimentation

Rationalisez les flux de travail, simplifiez les tâches et donnez aux opérateurs les moyens d'atteindre une productivité maximale.

Libérer le potentiel caché

Créez des solutions logicielles sur mesure avec FOCAS LIBRARY et la personnalisation intuitive de l'écran pour obtenir un avantage concurrentiel.

Renforcer l'expertise

Réglez les machines avec précision, développez des macros personnalisées et optimisez les performances grâce à de puissants outils de configuration.

Options

Découvrez nos options CNC pour la personnalisation

Bibliothèque FOCAS

Boostez vos opérations CNC ! Connectez-vous facilement à votre machine CNC via Ethernet ou fibre optique. Personnalisez les fonctions, modifiez les macroprogrammes et bénéficiez d'un accès intuitif aux outils CNC avancés.

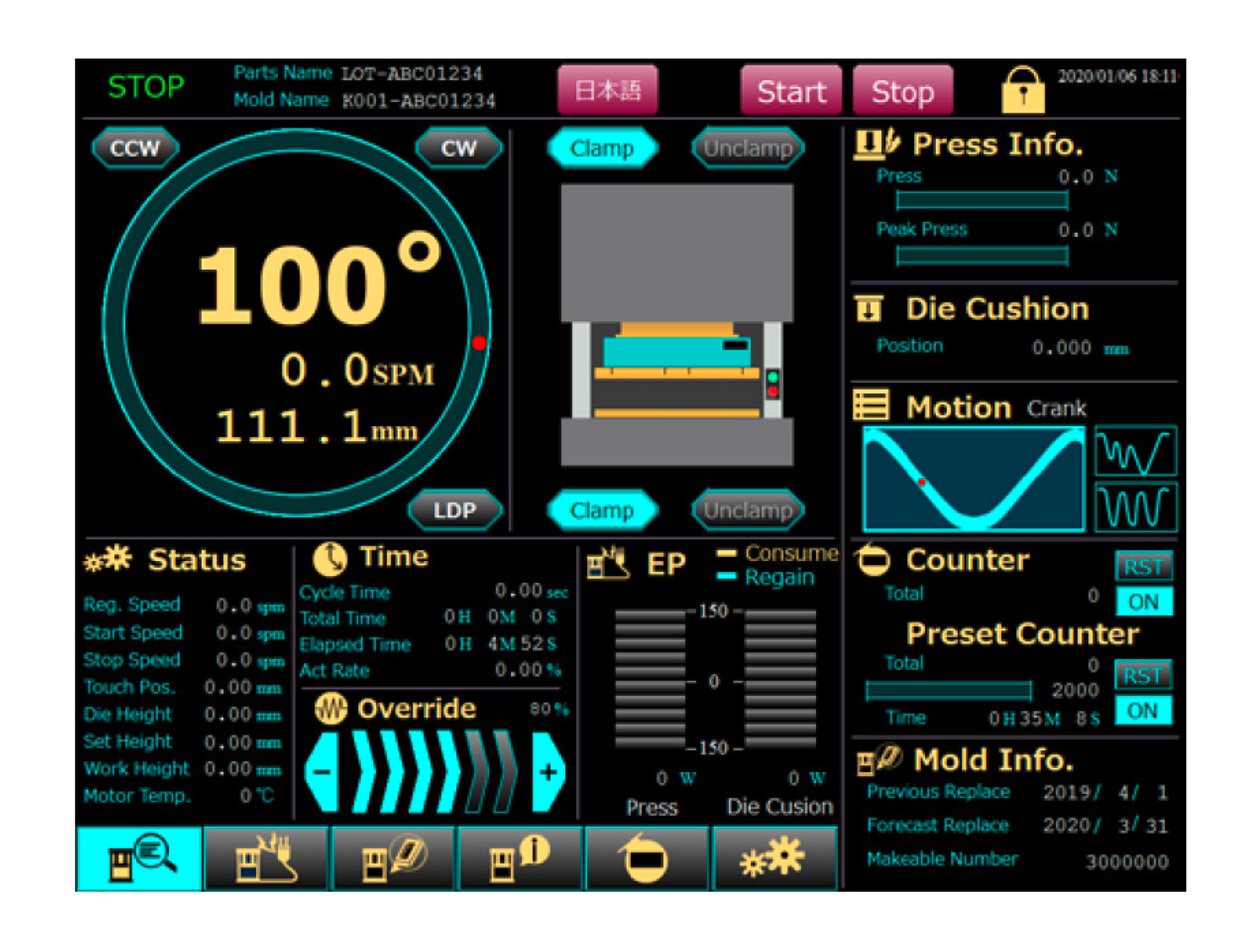

Personnalisation de l'écran - FANUC PICTURE

Personnalisez en toute transparence l'interface opérateur et les écrans IHM pour les tâches complexes. Une personnalisation inégalée, des interfaces améliorées, un fonctionnement fluide et des tableaux de commande sur mesure garantissent une expérience utilisateur optimale.

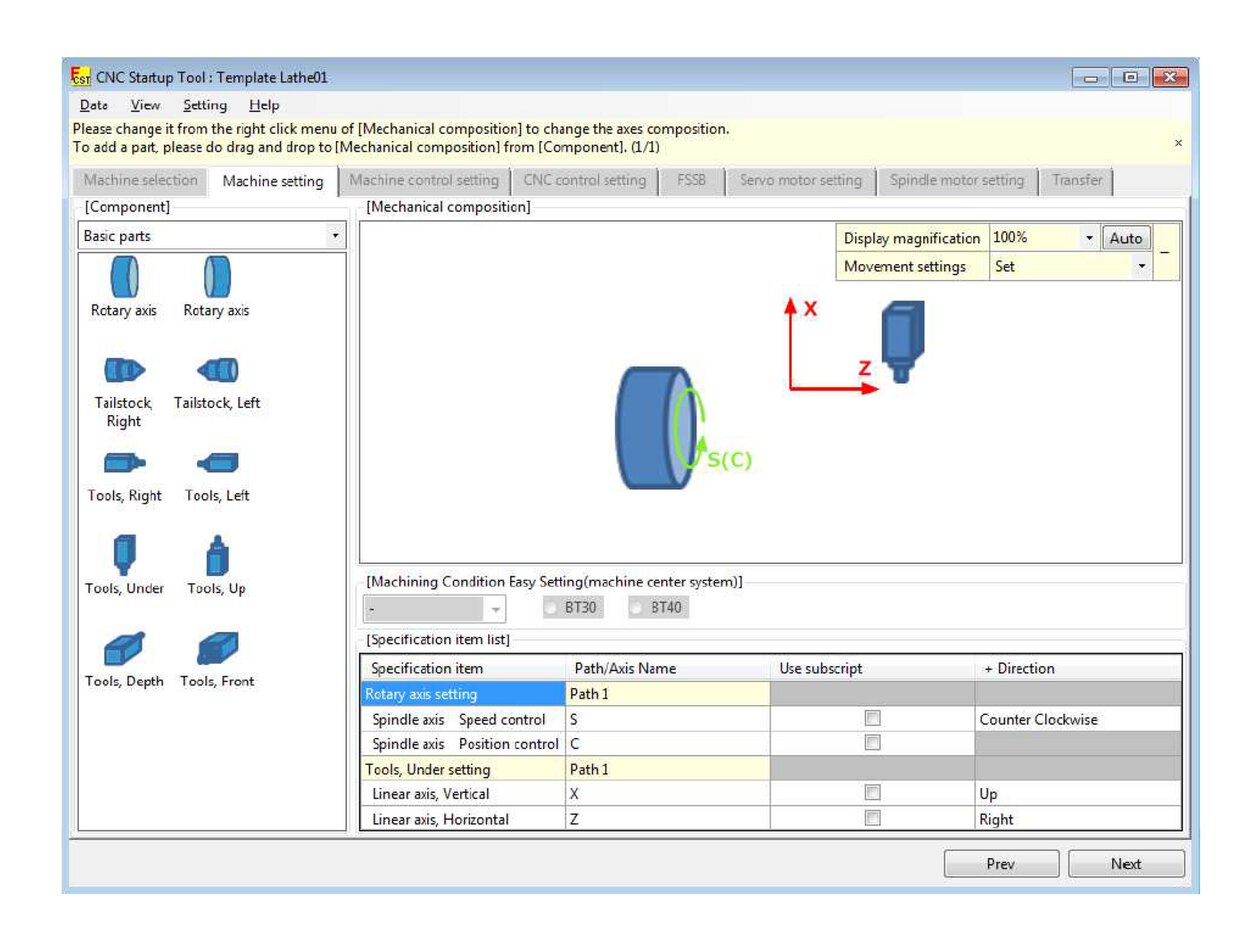

Outils de configuration - FANUC Ladder III, Kit de développement d'applications CNC, Outil de rég...

Améliorez l'efficacité de vos opérations industrielles grâce à nos outils. Simplifiez la programmation, personnalisez les systèmes et obtenez des réglages efficaces et précis pour une productivité accrue.

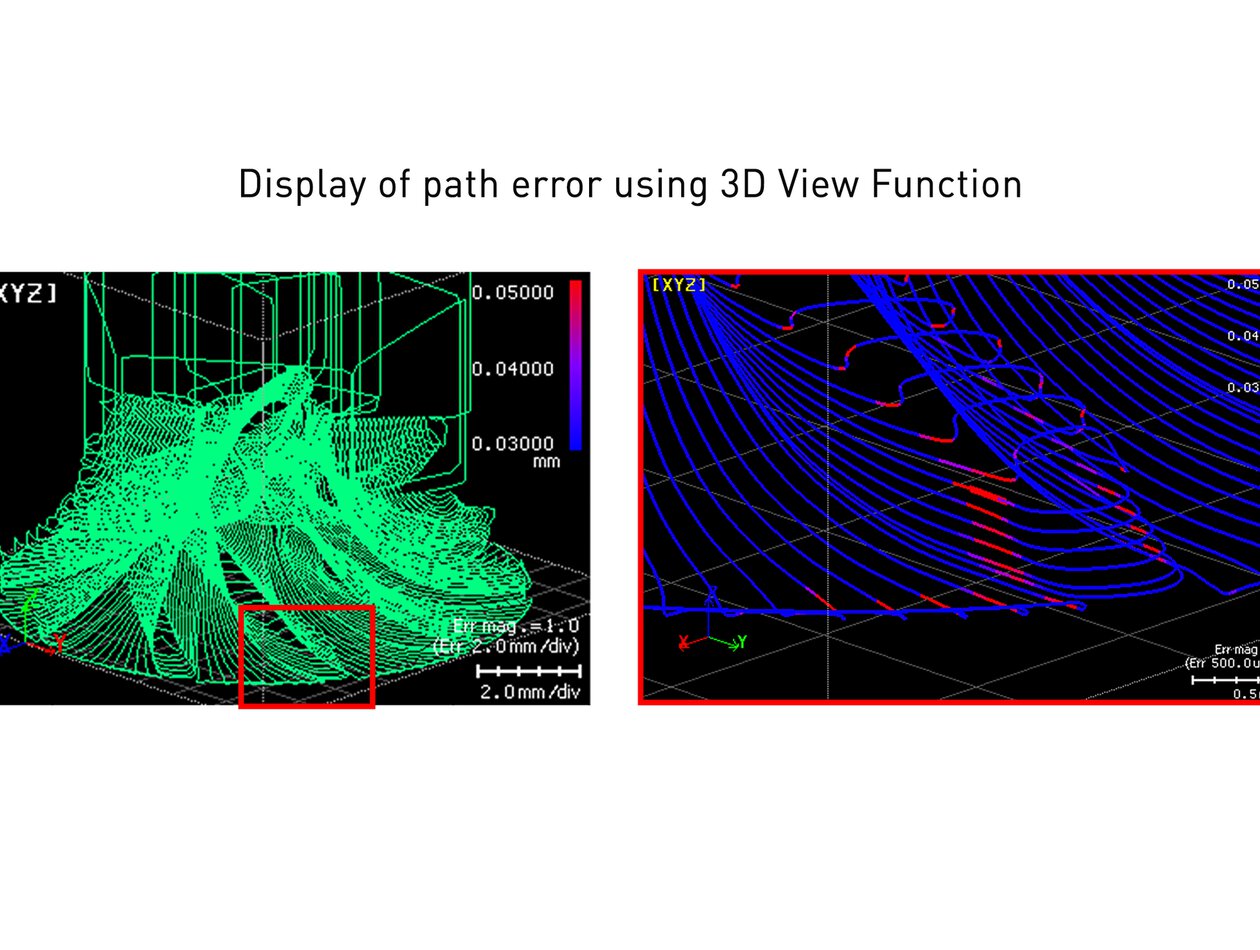

GUIDE SERVO

Boostez l'automatisation grâce à une technologie servo de pointe. Faites l'expérience de la précision, de l'intégration parfaite et des performances optimales. Durable, économe en énergie, avec une as

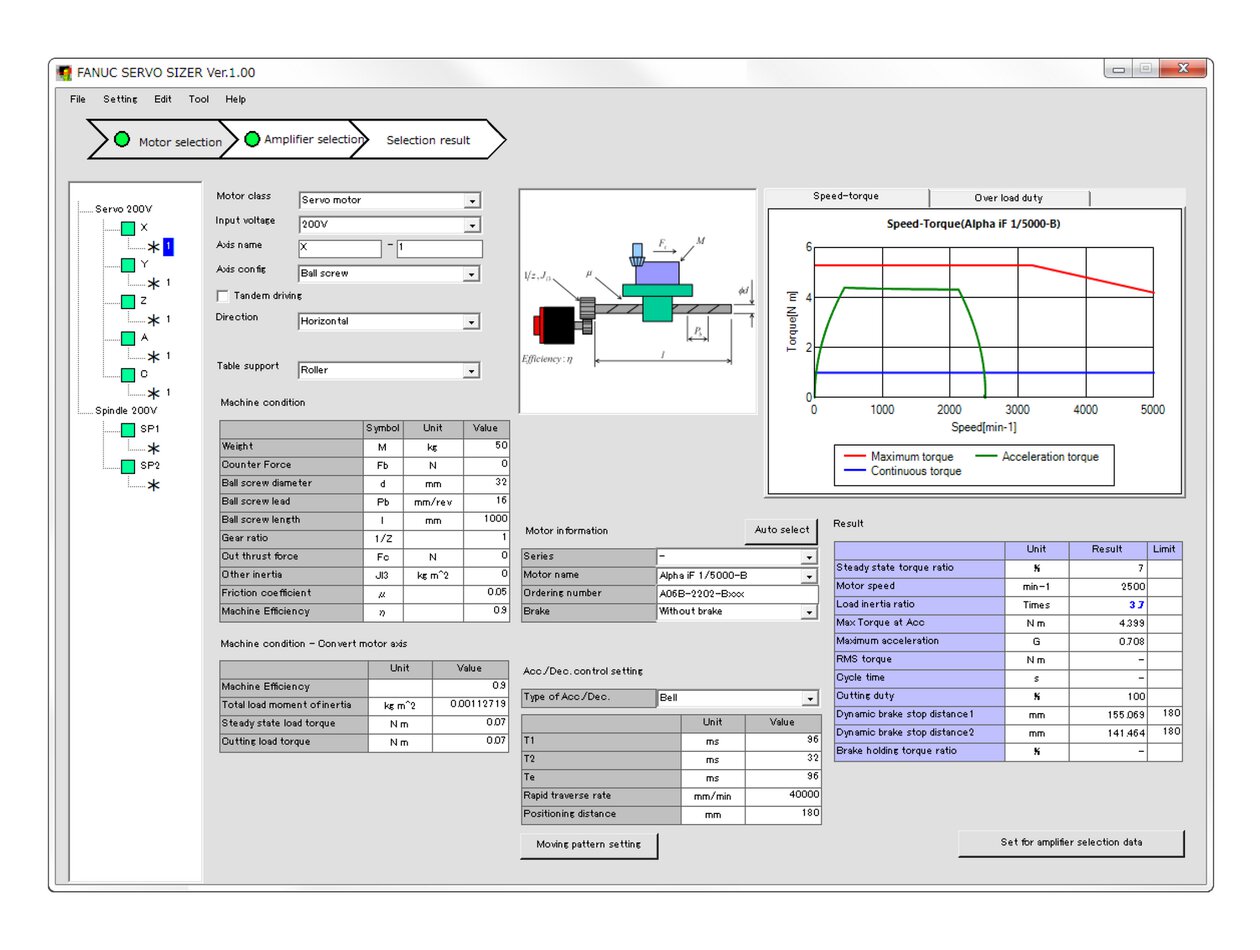

Servo Sizer

Sélectionnez facilement les moteurs et les amplificateurs grâce à FANUC Servo Sizer. Saisissez vos spécifications et vos conditions de fonctionnement pour obtenir des recommandations optimales sur les moteurs et les amplificateurs. Gratuit et intuitif.

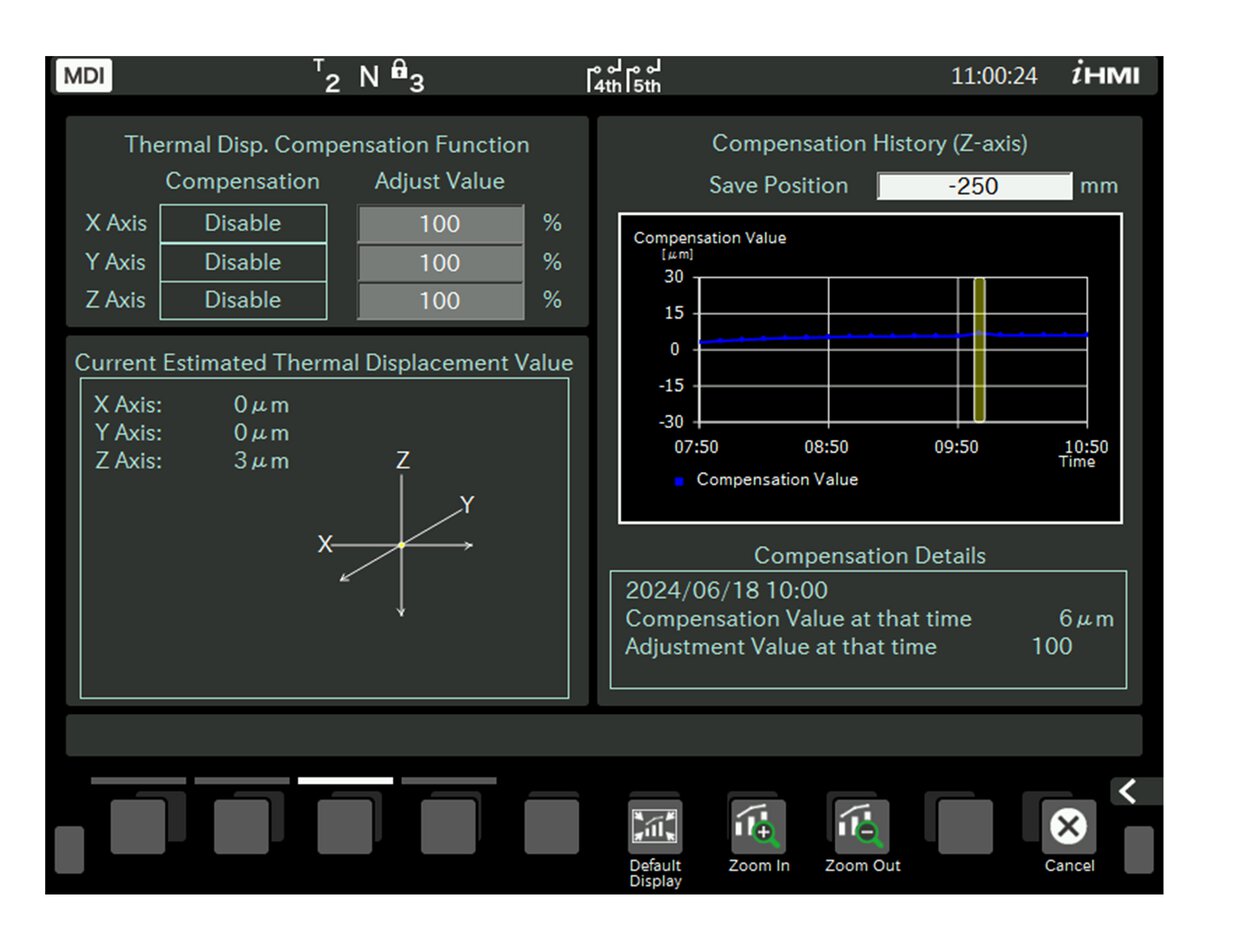

Compensation du déplacement thermique IA

Faites l'expérience d'une précision et d'une efficacité inégalées dans les machines industrielles. Notre solution minimise le déplacement thermique, ce qui garantit une précision constante, une réduction des temps d'arrêt et une meilleure productivité.

Prenez contact avec nous

Solutions

SERVICE CLIENT

ÉDUCATION

ACTUALITÉS ET MÉDIAS

A PROPOS DE FANUC

CONTACT