Placing Plastic Injection-Moulding into Packing Trays

Get Inspired

Robots in Dairy Production

Taking on demanding palletising tasks is child's play for robots. For complex applications, well thought-out development and design ensure production efficiency and competitiveness.

Cosmetics Manufacturer Sees the Beauty of FANUC Automation

Erkul Cosmetics in Turkey benefits from a myriad of quality and efficiency benefits provided by various high-performance FANUC automation products. This fast-growing cosmetics enterprise is looking to set a benchmark for manufacturing in its sector, supported by the competitive gains that FANUC solutions provide.

FANUC Robot Takes to Farming

Heavy lifting and physical strain are now a distant memory at Green Services. The automated palletising system featuring the FANUC robot is today providing safe and productive operation.

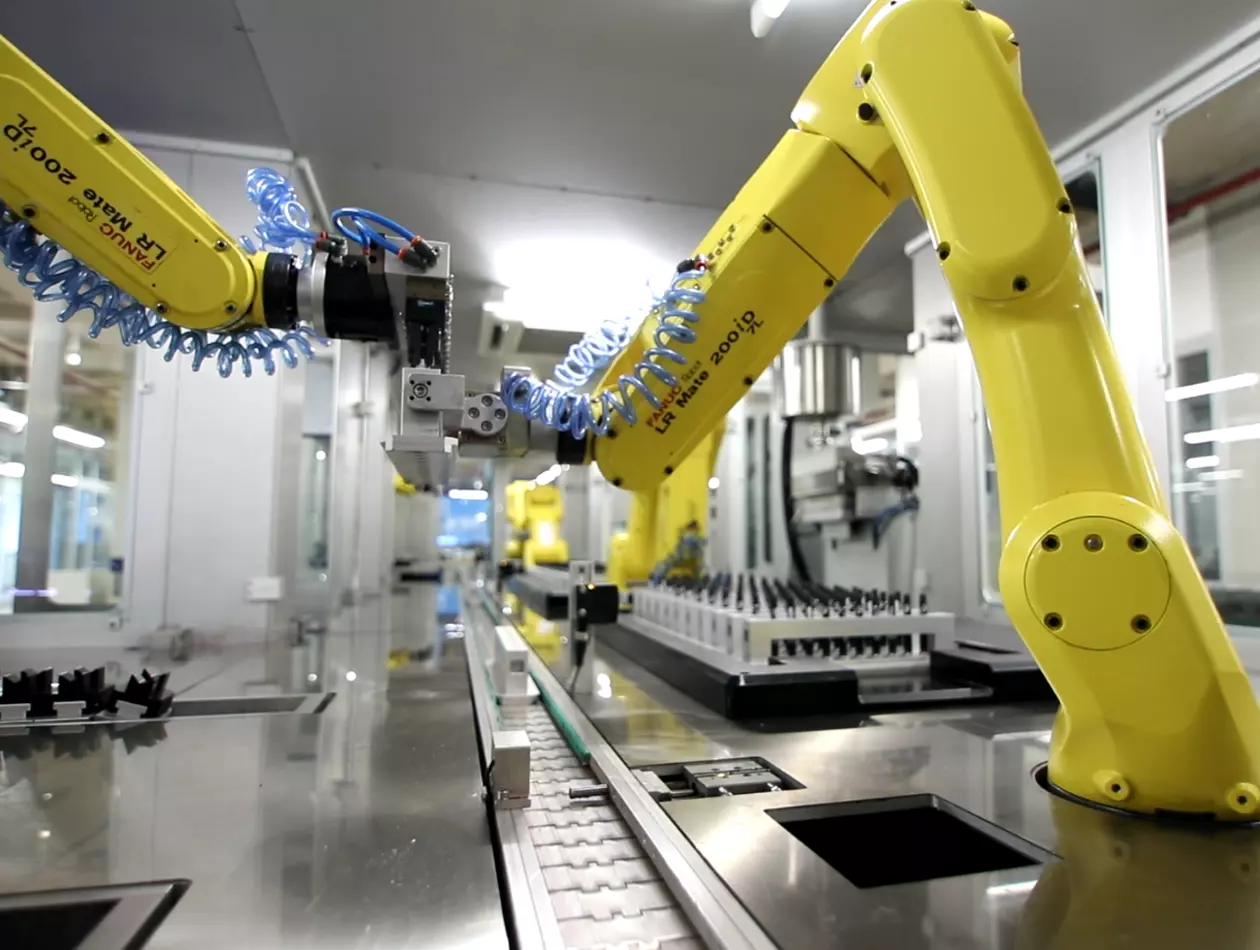

Fully Automated Assembly of Coffee Grinders

In the manufacture of popular household appliances such as coffee grinders, a number of prerequisites determine production success. For instance, only clearly structured, efficient and target-orientated processes will result in the required levels of production reliability. Achieving this ambition becomes significantly more realistic using automation, as market leader Eugster/Frismag AG can testify following its adoption of 14 FANUC LR Mate industrial robots and FANUC ZDT (Zero Down Time), which now enable the continuous automated assembly of a coffee grinder every 7 seconds.

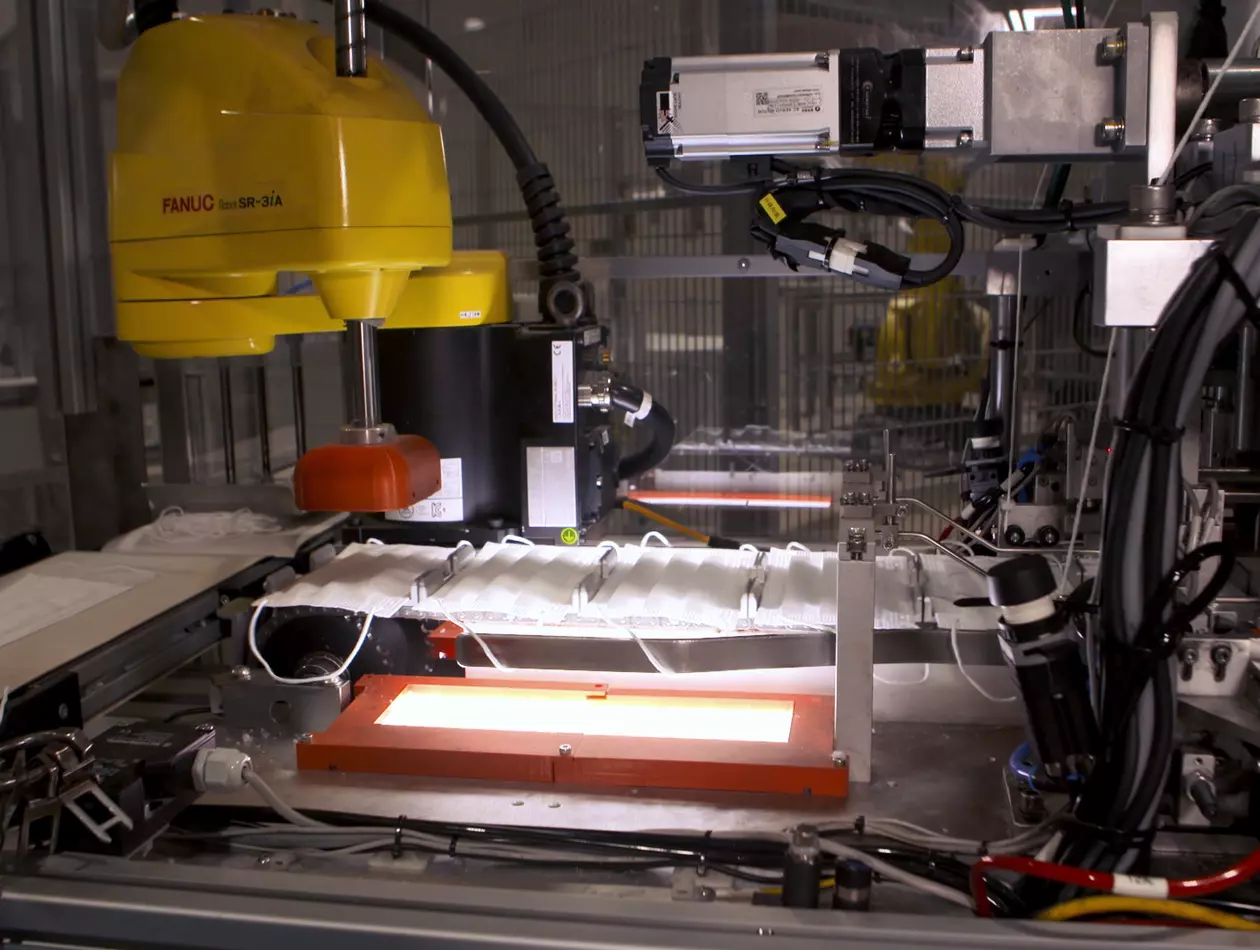

FANUC Robots Help Mask Producer Face up to the Challenge

When production demand accelerates dramatically in a short space of time, robots and automation can help meet requirements much faster than many realise. However, this outcome depends heavily on the selection of robots that are easy to install, program and commission.

FANUC Case Studies

Explore our comprehensive range of factory automation solutions, showcased in detailed case studies, and designed to optimise and streamline any manufacturing process.

Machine Tending