FANUC Palletising Robots

Power Up Your End-of-Line Efficiency

Streamline your end-of-line operations and boost productivity with FANUC's industry-leading palletising robots. Designed for efficiency and reliability, our innovative robots tackle even the most demanding palletising tasks, handling diverse products and configurations with precision and speed.

To select the correct automated palletising solution, consider payload, reach, duty, cycle time and floor space. Don’t forget the weight of your end of arm tool, dressout and product when selecting the desired payload range.

Get Inspired

Get Inspiration from Others' Success

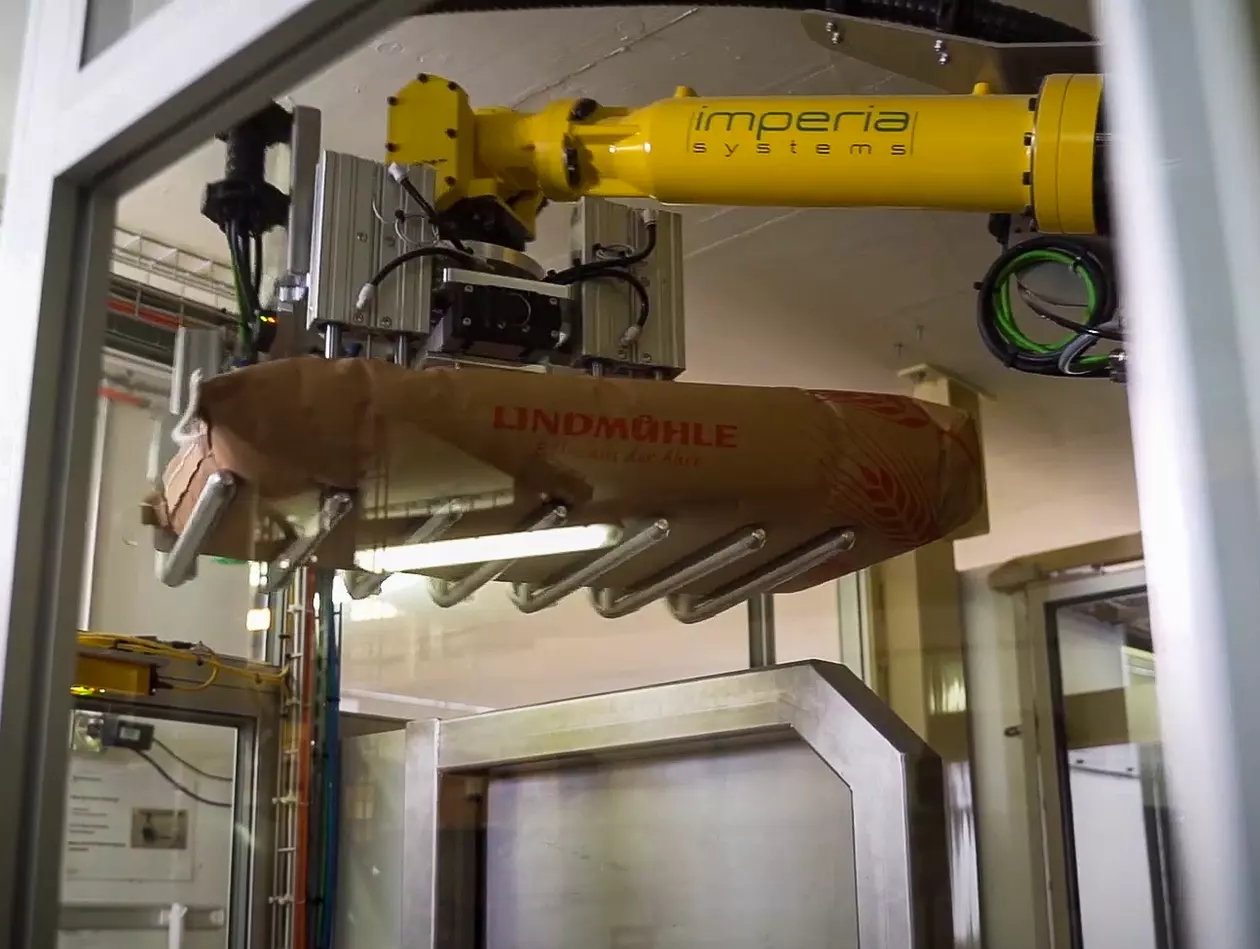

FANUC Robot Raises Palletising Capacity at Flour Plant

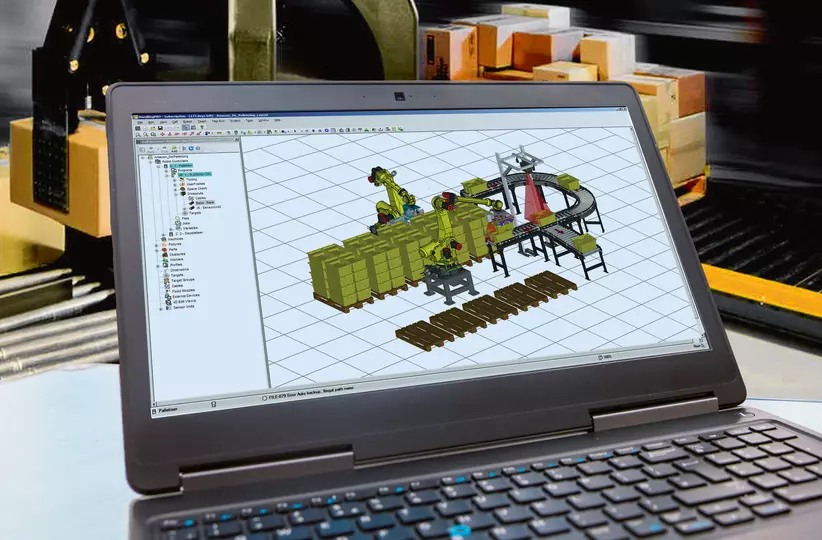

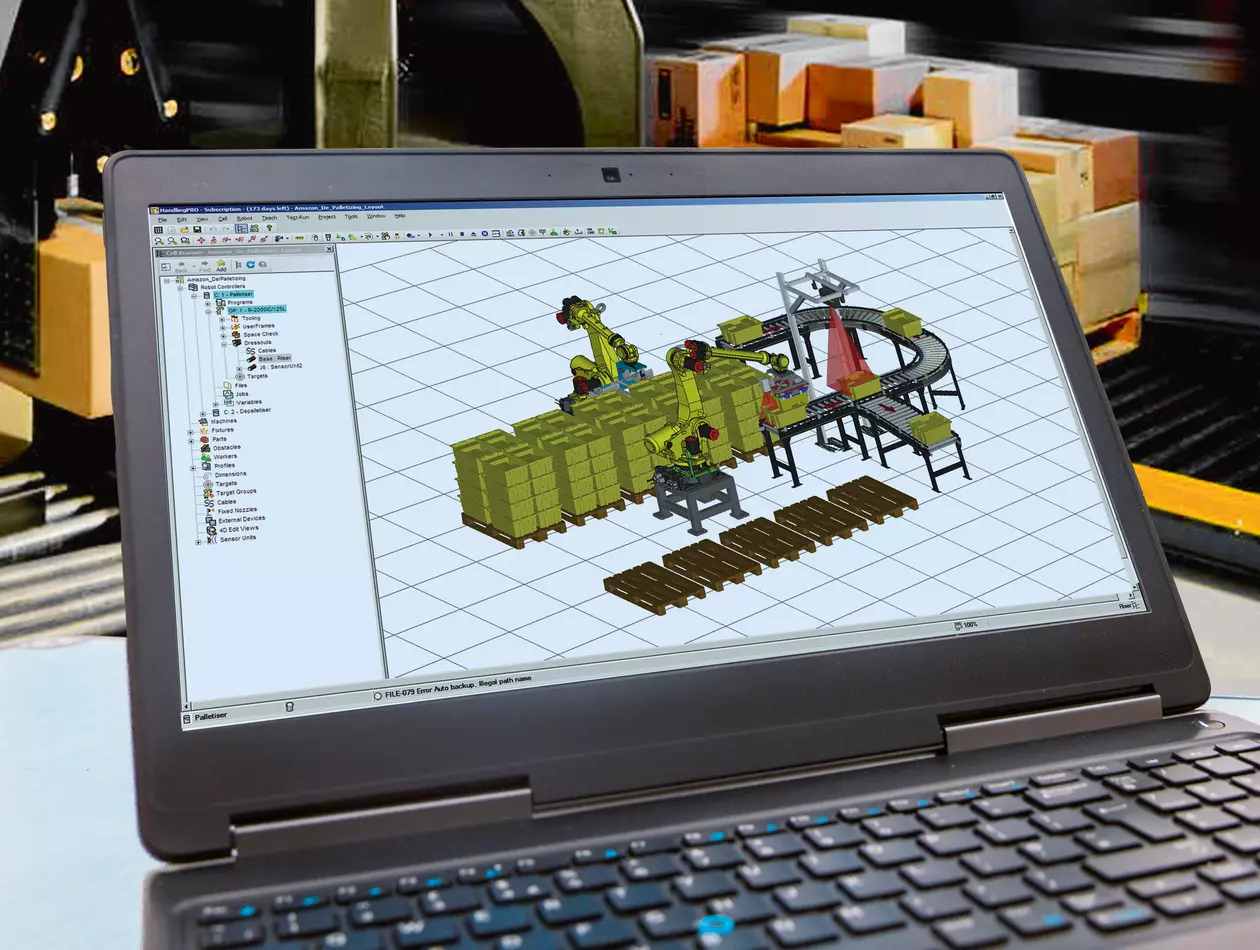

Taking the strain in heavy lifting operations is a classic application for industrial robots. However, implementing robots in lifting tasks not only provides physical relief to workers, it also has the potential to boost throughput, even where space is limited. Flour manufacturer Lindmühle is a case in point, where FANUC simulation software highlighted the optimal robot for the available working envelope.

FANUC Robots Extend the Benefits of Stretch Hood System

Keramik Makina, a FANUC system integrator, combined palletising and shrink hood systems with FANUC robots to form powerful end-of-line solutions at the paint factory of Polisan Kansai in Türkiye.

FANUC Robot Ends Packaging Bottleneck at Food Factory

When implementing improvements to a bottleneck process the common outcome is the emergence of a new bottleneck elsewhere in the factory. Whereas in years gone by this situation would necessitate the recruitment of more labour, automation has today become industry’s go-to solution for bottlenecks. Just ask Brunos, a leading producer of salad dressings, which knows all about the benefits that a robot can bring.

Perfect Fit for Your Application

Palletising

Tailored Solutions for Your Industry

Robotics & Automation for the Automotive Industry

Robotics & Automation for the Aerospace Industry

Food & Beverage

Warehousing, Logistics, Post & Parcel

Robotics & Automation for the Medical Industry