M-710𝑖C/50

Get Inspired

Get Inspiration from Other's Success

Automation is the Best Medicine at DEMO

A key player in the pharmaceutical industry, significantly improved its production capabilities with FANUC's automated solutions. By integrating FANUC robots, DEMO optimised the filling, packaging, and labeling processes, resulting in enhanced efficiency, accuracy, and overall productivity in their operations.

Trio of FANUC Robots Boost Packing Efficiency at Inoverde

In a fast-moving fresh-food distribution plant, efficiency through automated packing operations is paramount to keep pace with demand. As a by-product of this approach, robot adopters also gain from less physical strain for employees, gentler handling of delicate produce like fruit and vegetables, and more a uniform and repeatable process. Among the latest factories to benefit from all this added value is the Bätterkinden, Switzerland facility of major food distributor Inoverde, where carrot filling, packing and palletising operations are benefiting from the introduction of three FANUC industrial robots.

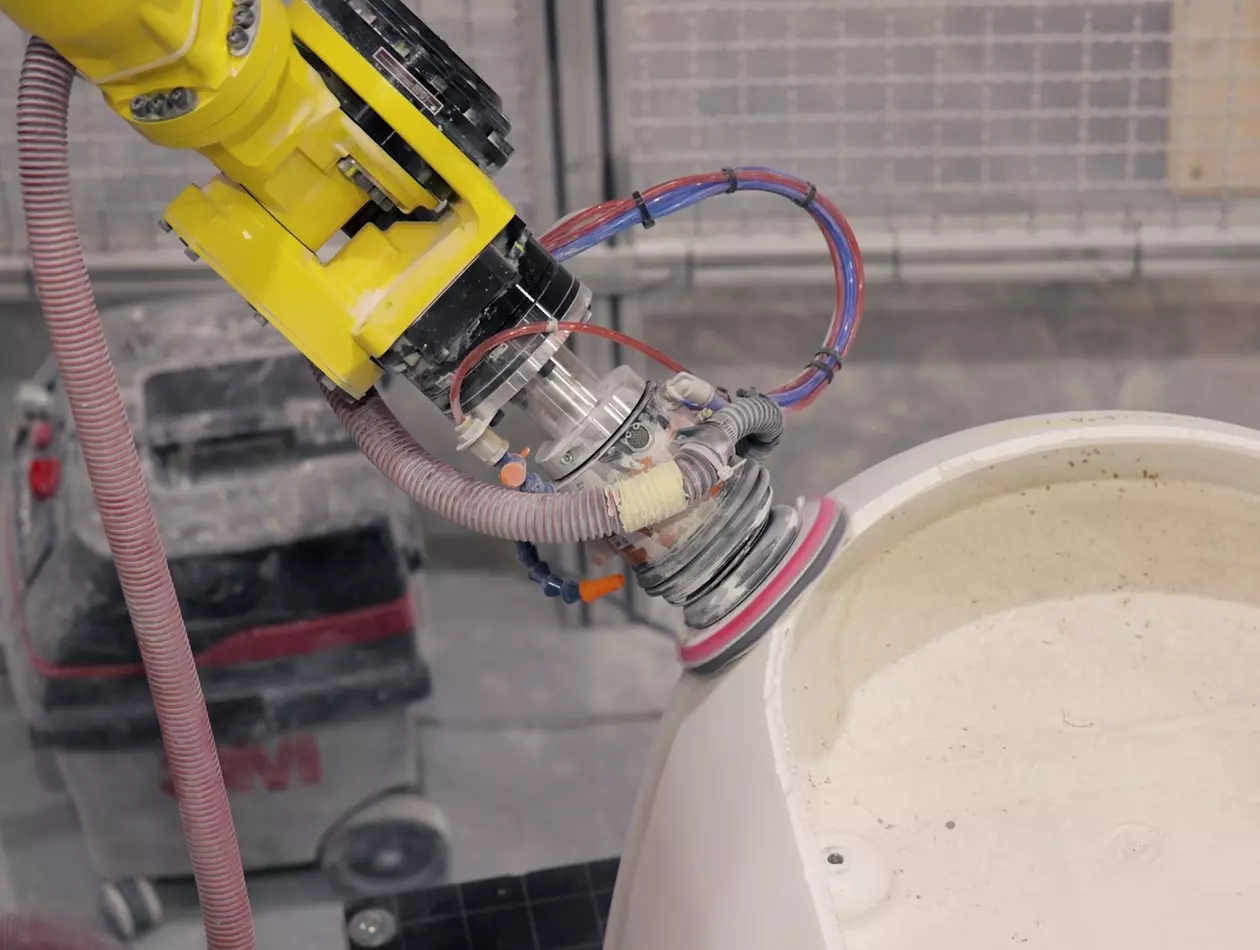

Sink and Bathtub Manufacturer Soaks Up the Benefits of FANUC Automation

Many tasks throughout industry are tailor-made for automation. Grinding and polishing are among this number, particularly when challenging materials make these processes slow and onerous for human operatives.

FANUC Robot Ends Packaging Bottleneck at Food Factory

When implementing improvements to a bottleneck process the common outcome is the emergence of a new bottleneck elsewhere in the factory. Whereas in years gone by this situation would necessitate the recruitment of more labour, automation has today become industry’s go-to solution for bottlenecks. Just ask Brunos, a leading producer of salad dressings, which knows all about the benefits that a robot can bring.

Perfect Fit for Your Application

Material Handling

Tailored Solutions for Your Industry

Robotics & Automation for the Aerospace Industry

Robotics & Automation for the Automotive Industry

Electric Vehicles

Electronics

Food & Beverage

Robotics & Automation for the Medical Industry