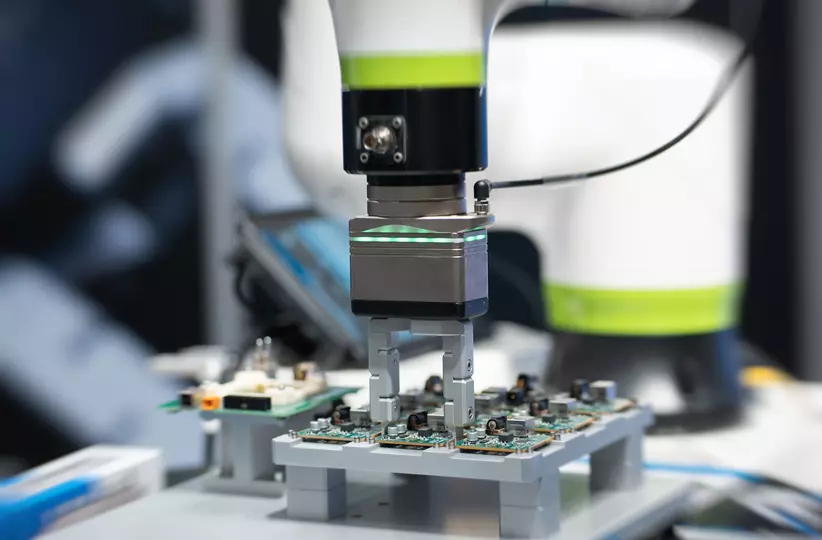

Assembling

Streamline your Assembly Process with FANUC Assembling Robots

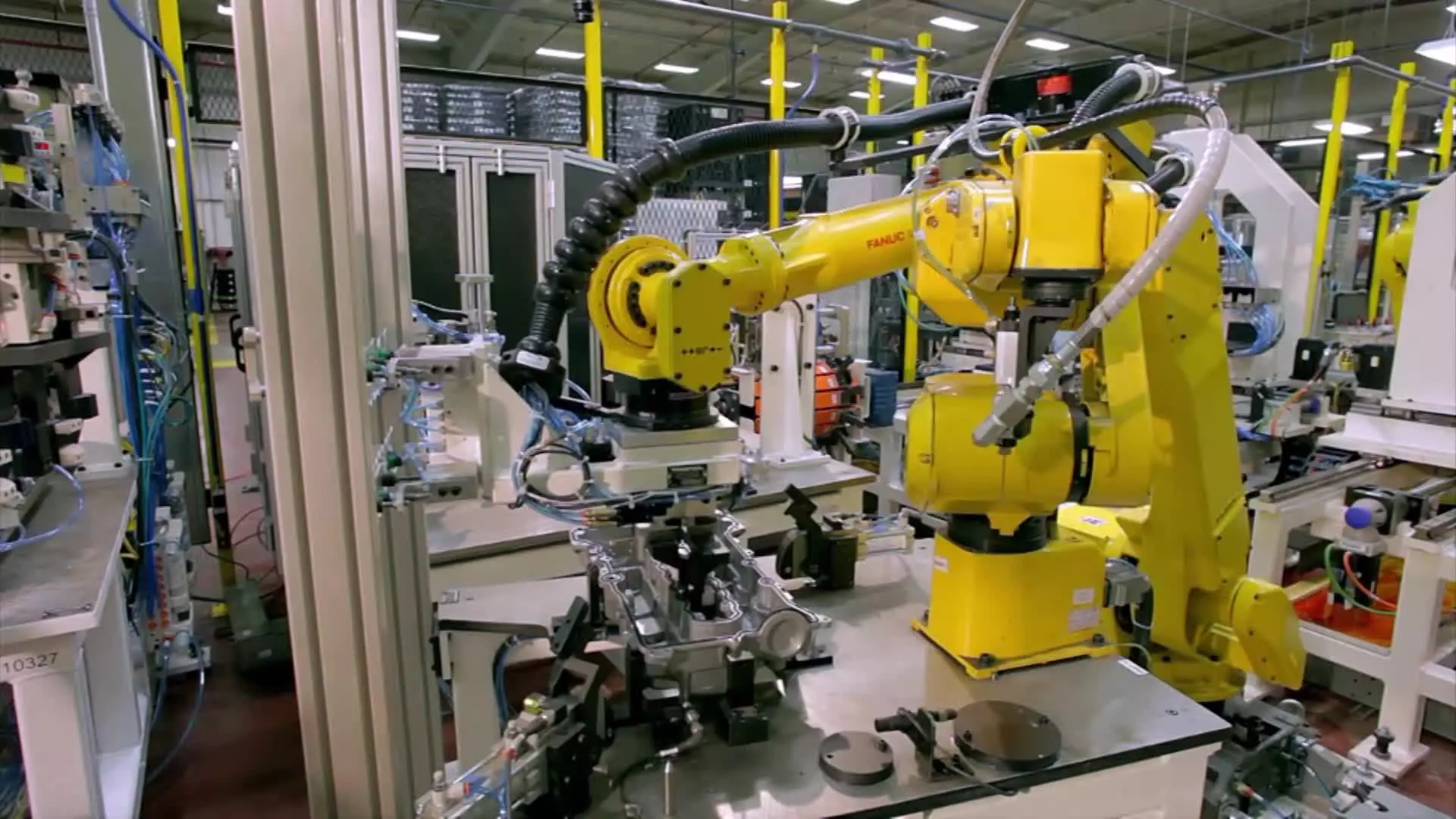

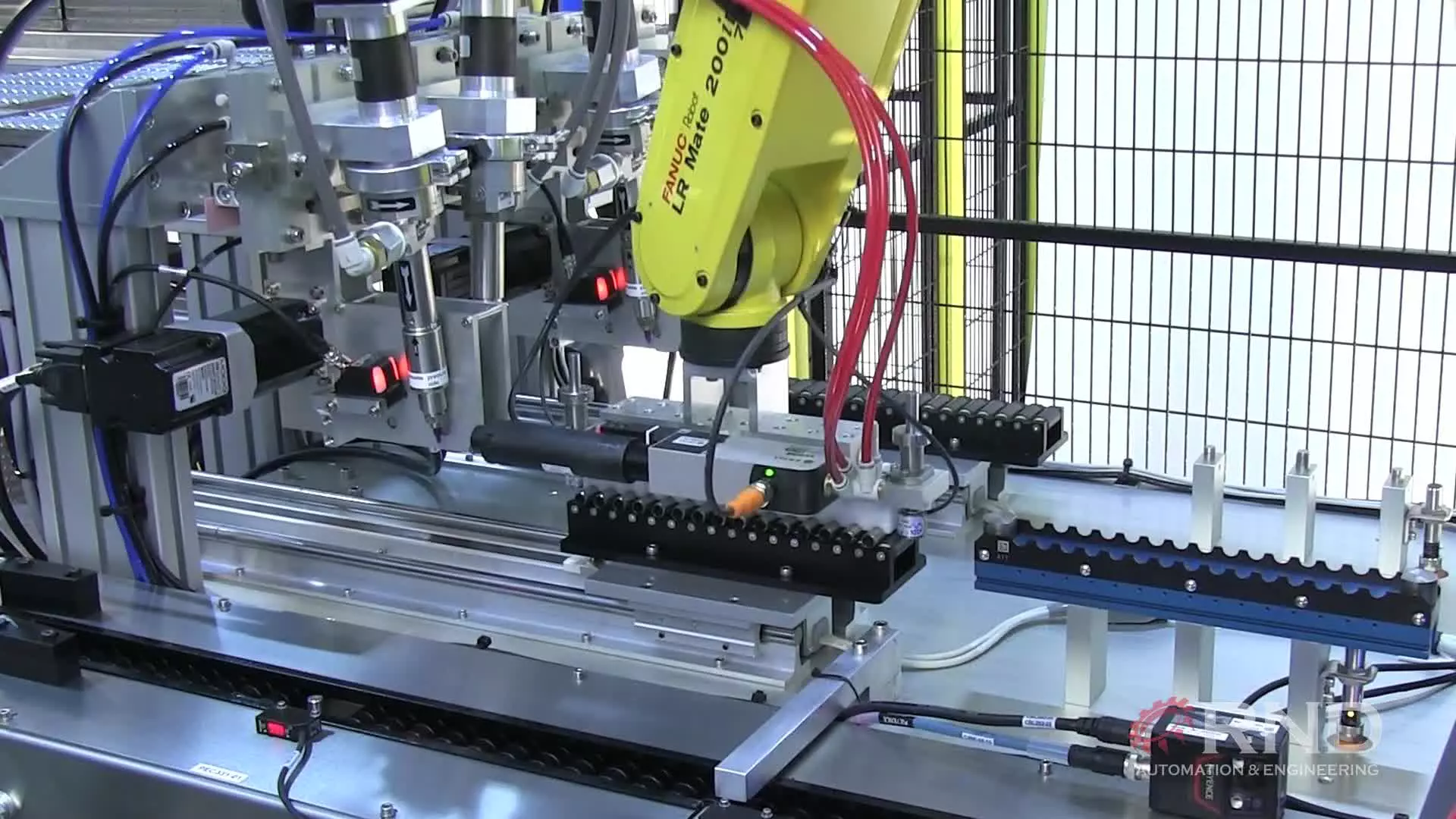

FANUC assembly robots are designed for high efficiency and precision. They feature advanced technology for enhanced performance, including high-speed operations, large payload capacities, and exceptional accuracy. These robots are built with durable materials, ensuring longevity and reliability in various industrial environments. They come equipped with user-friendly interfaces and are compatible with peripheral devices, making integration into your existing systems seamless. Safety is a priority and ensure smooth operation. Additionally, FANUC robots offer flexibility in installation and are suitable for a wide range of applications, from small parts assembly to heavy-duty tasks.

Get Inspired

Get Inspiration from Other's Success

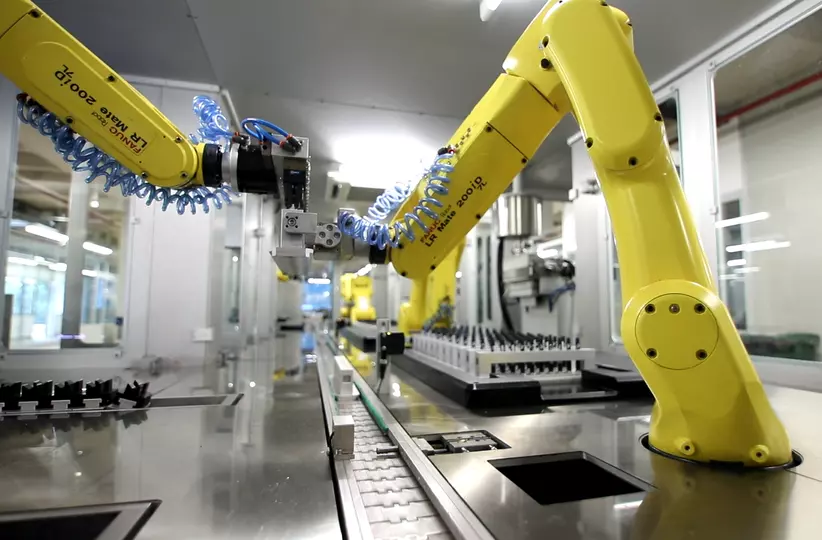

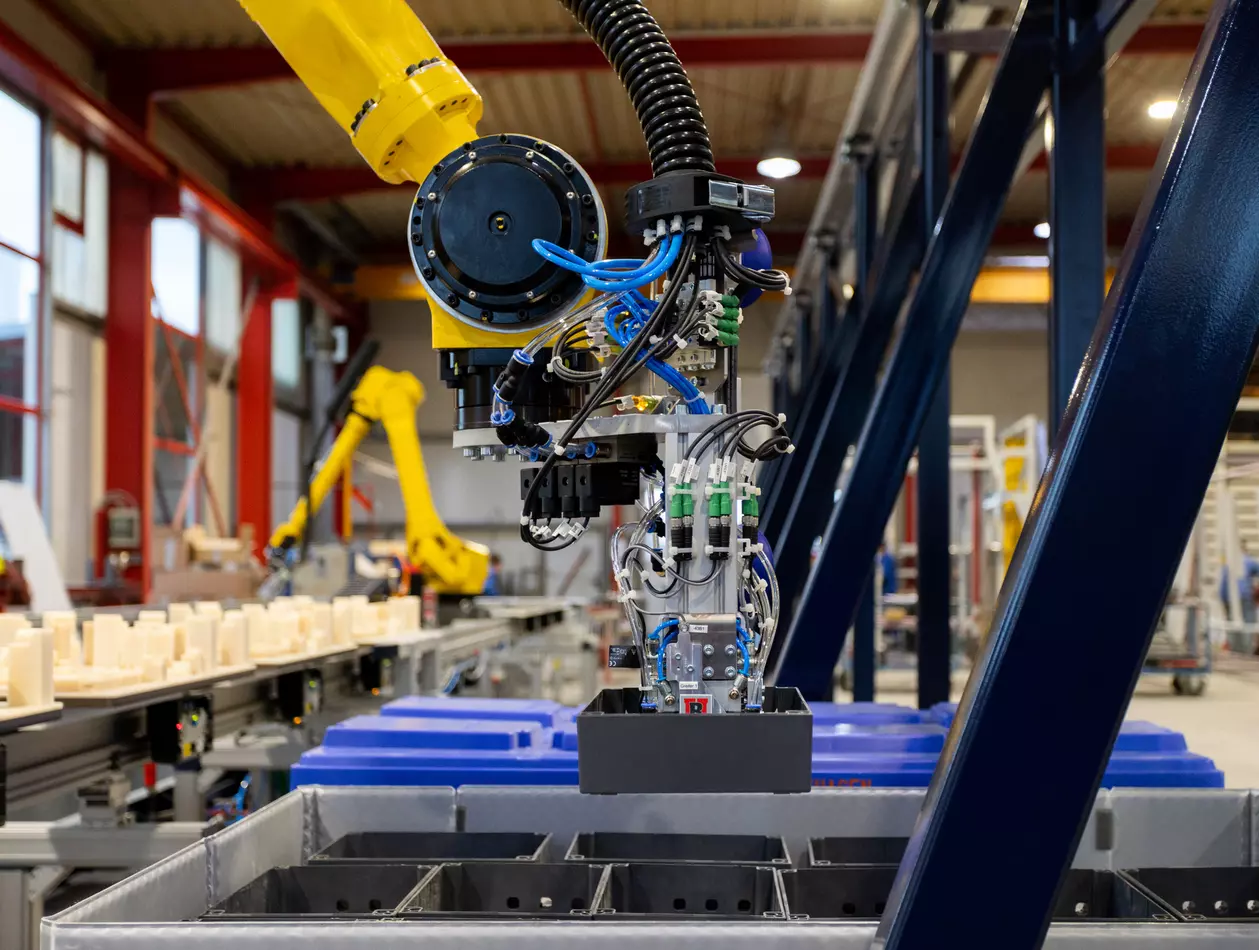

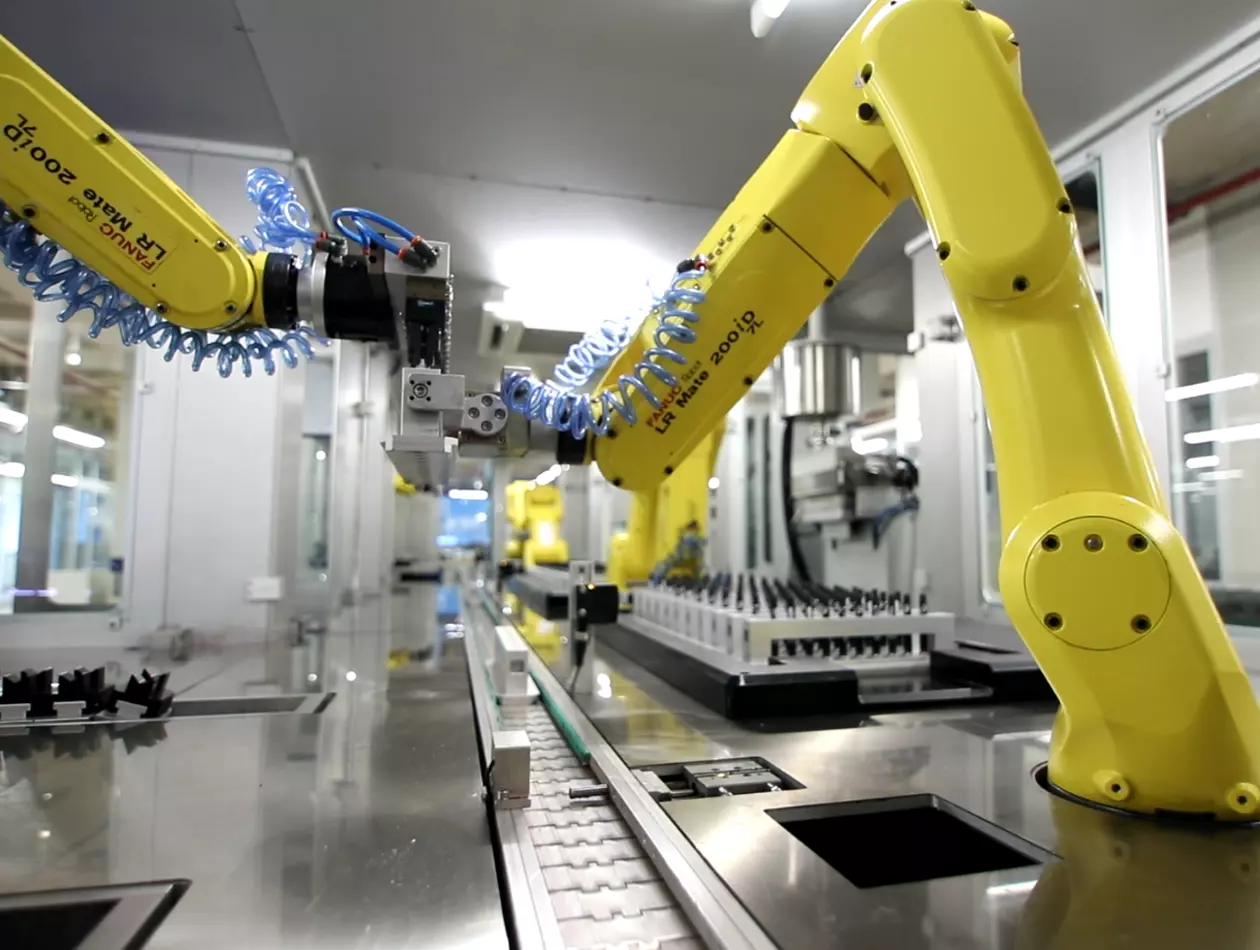

Fully Automated Assembly of Coffee Grinders

In the manufacture of popular household appliances such as coffee grinders, a number of prerequisites determine production success. For instance, only clearly structured, efficient and target-orientated processes will result in the required levels of production reliability. Achieving this ambition becomes significantly more realistic using automation, as market leader Eugster/Frismag AG can testify following its adoption of 14 FANUC LR Mate industrial robots and FANUC ZDT (Zero Down Time), which now enable the continuous automated assembly of a coffee grinder every 7 seconds.

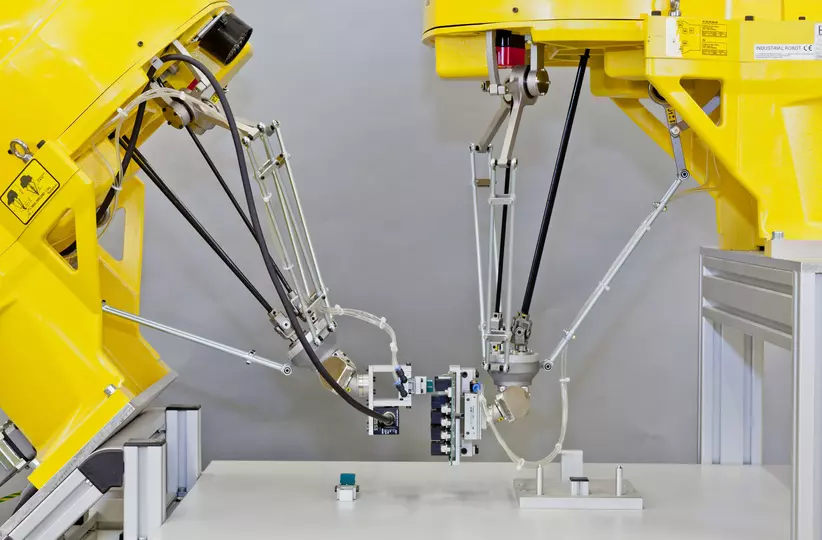

Assembly Order Picking with Two Robots on a 13 Metre Traversing Axis

Automating a production line can be done flexibly and in a small space. Customised solutions and safety software functions are a key element for successful implementation.

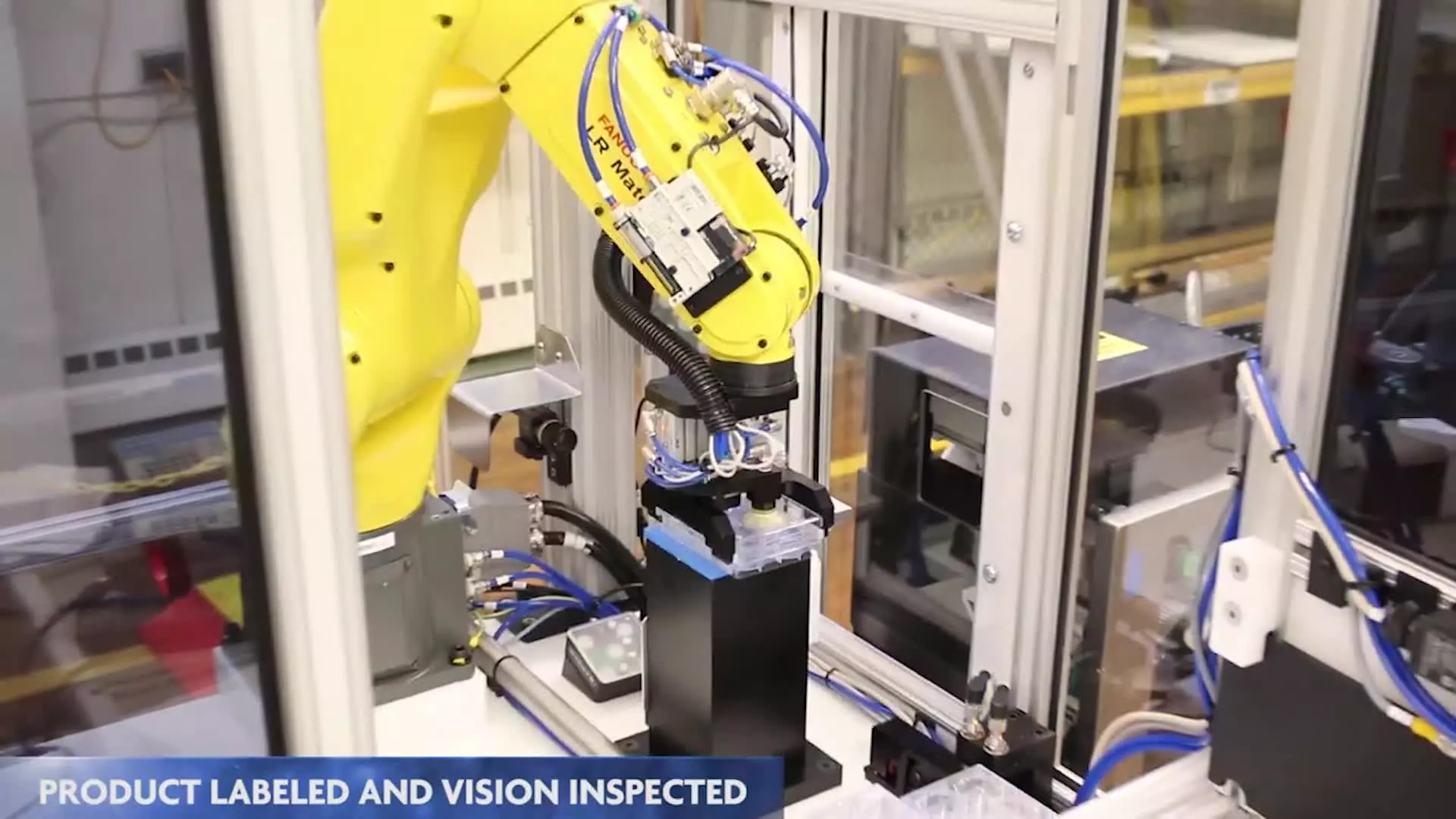

Cosmetics Manufacturer Sees the Beauty of FANUC Automation

Erkul Cosmetics in Turkey benefits from a myriad of quality and efficiency benefits provided by various high-performance FANUC automation products. This fast-growing cosmetics enterprise is looking to set a benchmark for manufacturing in its sector, supported by the competitive gains that FANUC solutions provide.

Transform your Industry with FANUC Assembly Robots

Automotive

Aerospace

Electric Vehicles

All Industries

Learn More about our Infinite Possibilities

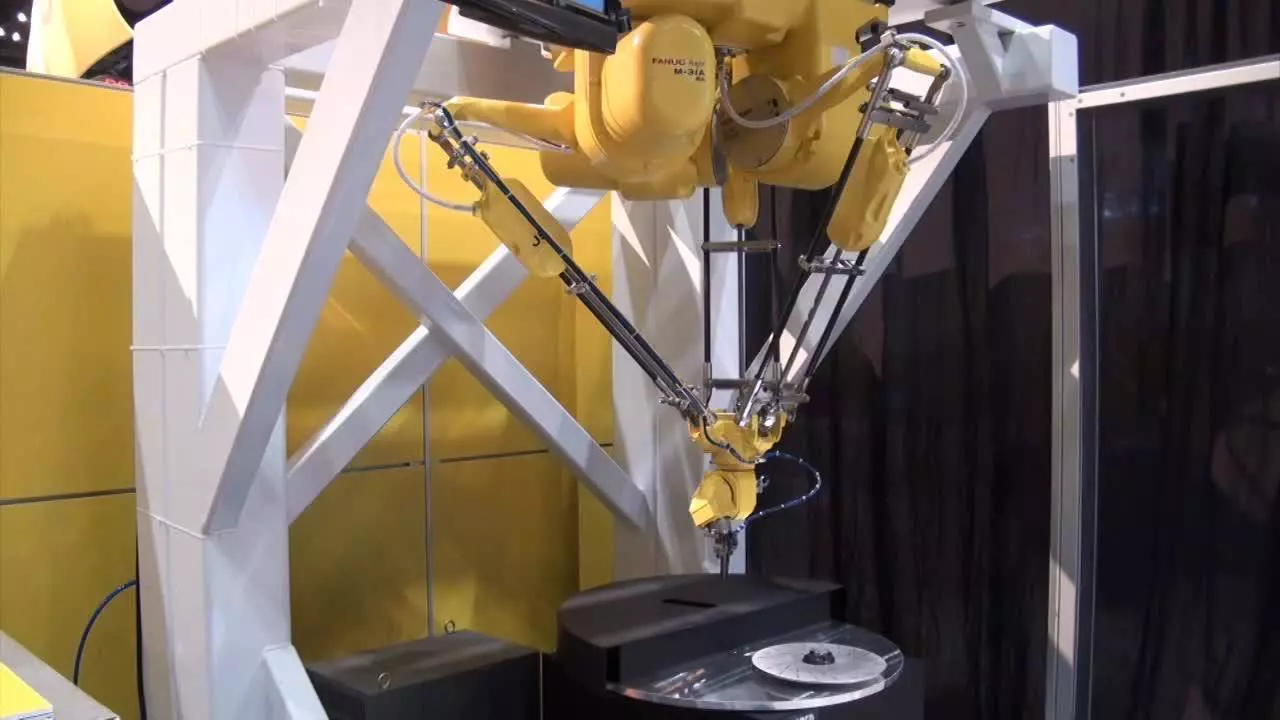

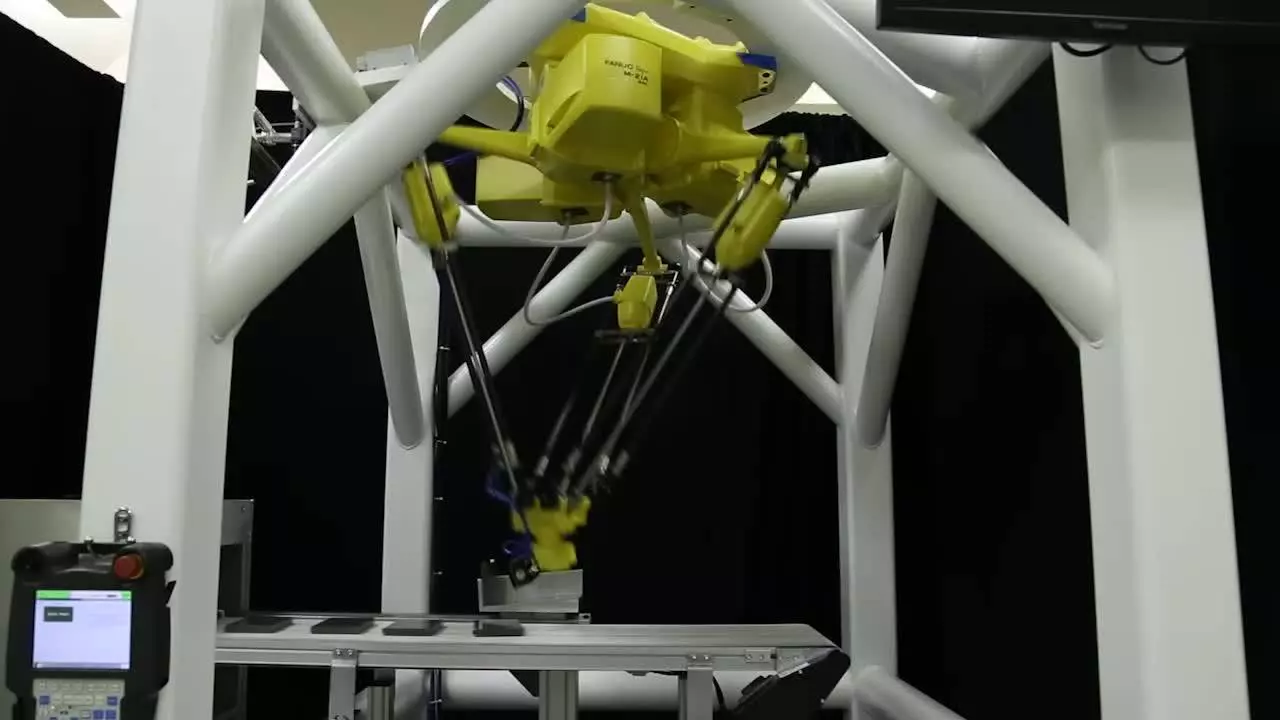

Six-Axis FANUC M-3iA Delta Robot Assembles a Blower Fan

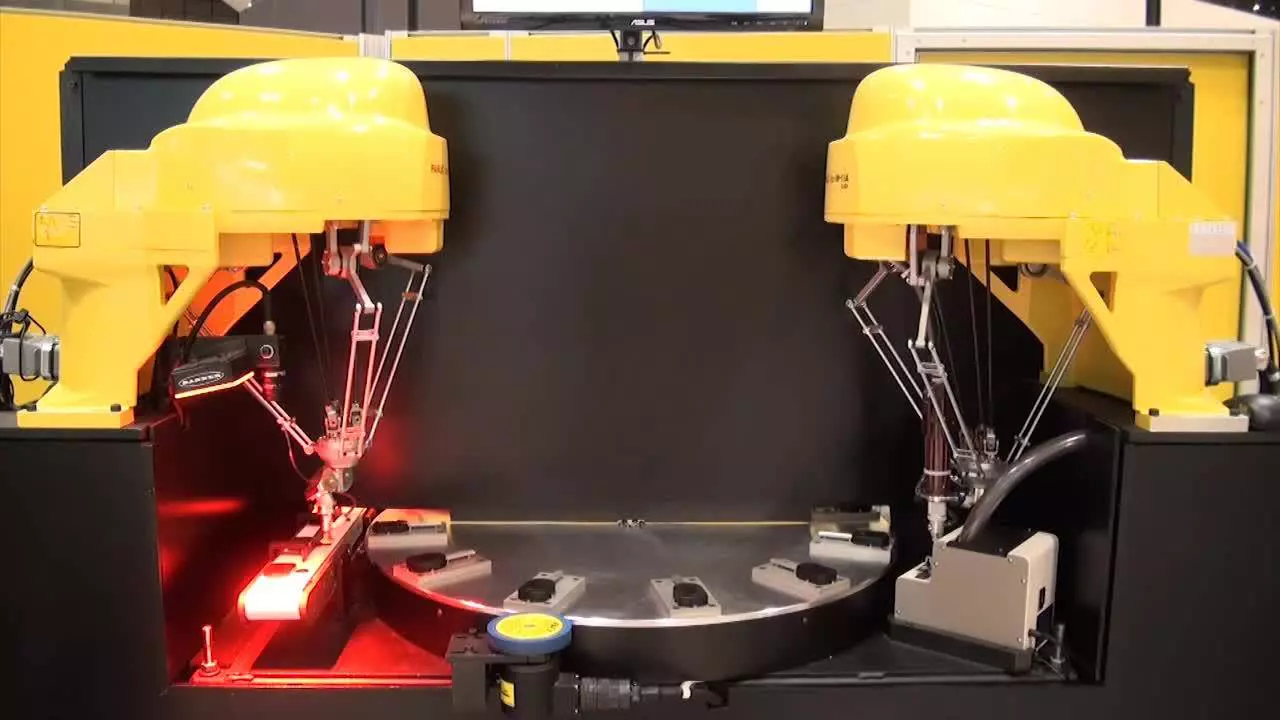

FANUC M-1iA Robot - Key Fob Assembly

FANUC M-1iA Robot - Electric Connector Assembly

FANUC M-2iA/3AL Robot Assembles Car Battery Cells with Visual Line Tracking

FANUC SR-3iA SCARA Robot Battery Pack Assembly

Mobile Collaborative Robot - FANUC CR-7iA/L Uses AGV to Move Between Robotic Assembly Stations

Our Solutions for Other Applications

Boost Efficiency, Precision, and Productivity with FANUC's Solutions for Different Applications

From high-precision robotics to smart automation, we provide the solutions to elevate your manufacturing processes.